Pneumatic Conveyor System: Design, Types & Uses

Handling powders, granules, and bulk materials efficiently is a major challenge in automated production environments. Spillage, contamination, dust control, and inconsistent flow often disrupt operations. A pneumatic conveyor system addresses these pain points by providing enclosed, clean, and automation-ready material transport.

What Is a Pneumatic Conveyor System?

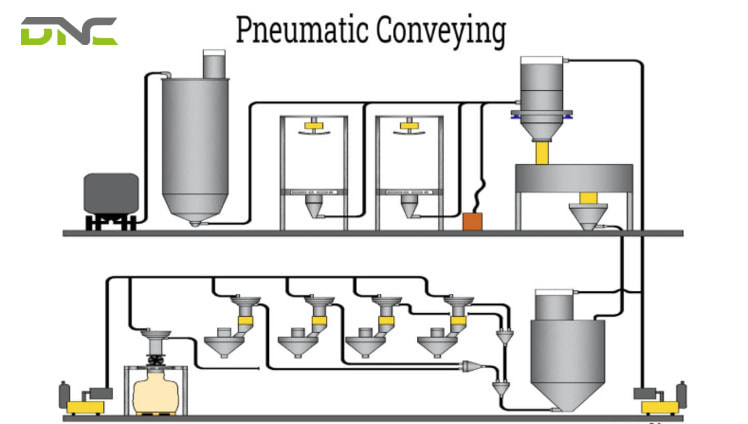

A pneumatic conveyor system is an industrial material handling solution that transports bulk materials through pipelines using air or gas flow. Instead of mechanical belts or rollers, the system relies on controlled air pressure or vacuum to move powders, granules, and small solids efficiently. This enclosed conveying method helps prevent contamination, reduce dust emissions, and maintain product integrity.

Pneumatic conveyor systems are widely used in automated production lines where hygiene, flexibility, and long-distance conveying are critical. Their ability to integrate with automation controls makes them suitable for modern manufacturing and processing environments.

How does a Pneumatic Conveyor System work?

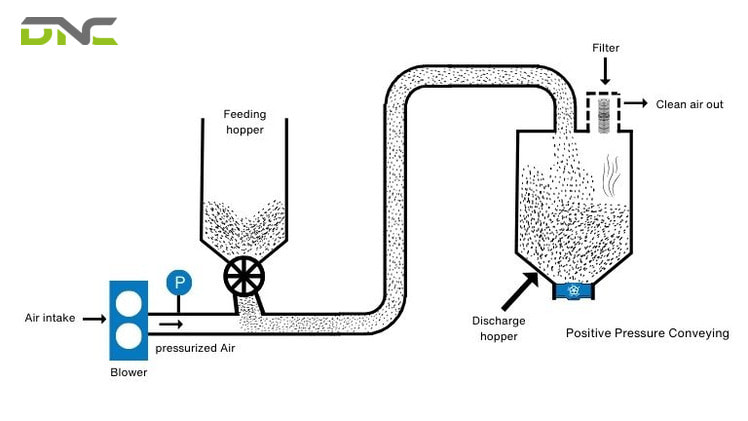

A Pneumatic Conveyor System works by using a high-pressure air stream or vacuum to move materials through a closed pipeline. Depending on the production requirements, the system can operate in two main modes: push (using compressed air) or suction (using vacuum).

The operating process consists of the following 5 steps:

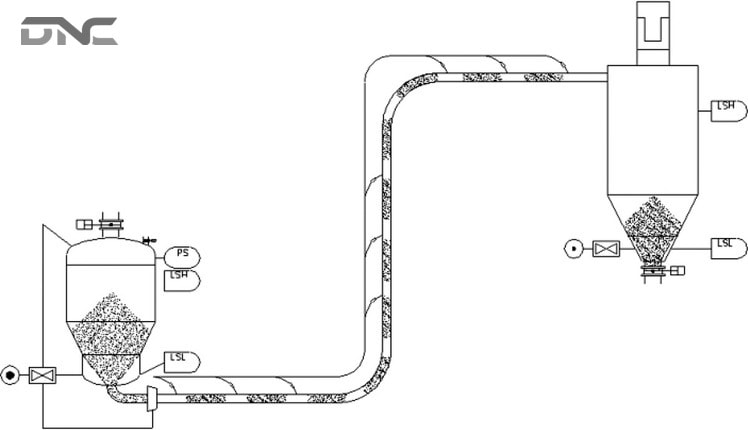

- Air supply: An air compressor or vacuum device creates a strong air stream in the pipeline system.

- Feeding: Materials are fed into the pipeline through a feeding device, such as a rotary valve, hopper, or feeder.

- Conveying: The air stream carries the material through the pipeline to the desired destination.

- Material separation: At the end of the pipeline, the system separates the material and the air (usually with a filter or cyclone separator), returning the material to a storage tank or further processing equipment.

- Gas release: The separated gas is discharged into the environment or recycled.

Pneumatic conveyor system can operate in two main modes: push (using compressed air) or suction (using vacuum)

What are the advantages of Pneumatic Conveyor System?

The application of Pneumatic Conveyor System in the factory brings many outstanding benefits compared to traditional transportation methods. Let’s explore the outstanding advantages of this conveyor with DNC:

- Saving installation space: Thanks to the flexible pipe system design, pneumatic conveyors can be easily arranged around other production equipment or go through narrow areas, helping optimize factory space.

- Limit dust and pollution: The closed pipe system helps to minimize dust and material leakage into the environment, ensuring hygiene and safety standards in production, especially in the food, pharmaceutical and chemical industries.

- Suitable for many types of materials: From fine powders, small particles to pellets or light materials, pneumatic conveyor system can handle them effectively thanks to the ability to adjust pressure and air flow.

- Increased productivity: Thanks to its continuous, high-speed and fully automated transport capabilities, pneumatic conveyor systems help shorten material loading times, reduce waiting times, thereby increasing the total production output of the factory.

- High integration capabilities: Pneumatic conveyors can be programmed and connected to automated production equipment such as packaging machines, storage silos or the overall production line, increasing efficiency and reducing operating costs.

What are the advantages of Pneumatic Conveyor System?

What are the disadvantages of Pneumatic Conveyor System?

In addition to its outstanding advantages, Pneumatic Conveyor System also has some limitations that businesses need to consider before investing.

- High energy consumption: The system requires air compressors or vacuum generators to operate continuously, resulting in higher power consumption than some traditional mechanical conveying systems.

- High initial investment costs: Installing pneumatic systems, closed pipelines and related equipment requires a relatively large initial investment cost, especially for factories that need to transport large volumes or long distances.

- Risk of pipe wear: With highly corrosive or abrasive materials (such as metal powders, sand, etc.), the pneumatic conveying process can wear out the pipes over time, requiring more frequent replacement or maintenance.

Pneumatic Conveyor System also has some limitations that businesses need to consider before investing.

Pneumatic Conveyor System vs Mechanical Conveyor

Choosing between a pneumatic conveyor system and a mechanical conveyor depends on material characteristics, layout constraints, hygiene requirements, and automation goals. Understanding the fundamental differences between these two conveying methods helps engineers and decision-makers select the most efficient and cost-effective solution for long-term operation.

| Comparison Criteria | Pneumatic Conveyor System | Mechanical Conveyor System |

| Conveying method | Uses air or gas flow to transport materials through enclosed pipelines | Uses belts, rollers, screws, or chains for direct mechanical movement |

| Material type | Ideal for powders, granules, and fine bulk materials | Best for large, uniform, and solid items |

| Cleanliness | Fully enclosed design supports dust-free and hygienic conveying | Open or semi-enclosed, higher risk of dust and spillage |

| Layout flexibility | Highly flexible routing with vertical and horizontal conveying | Requires more space and fixed layouts |

| Automation compatibility | Easily integrated with automated control systems | Automation possible but often requires additional mechanical components |

| Energy consumption | Generally higher, especially in dilute phase systems | More energy-efficient for continuous, heavy-duty transport |

| Maintenance needs | Fewer moving parts, lower mechanical wear | Regular maintenance required for belts, rollers, and chains |

This comparison highlights how pneumatic conveyor systems excel in cleanliness, flexibility, and automation, while mechanical conveyors offer simplicity and energy efficiency for specific material handling applications.

How is the Pneumatic Conveyor System used in various industries?

- Food and beverage industry: Transporting powdered, granular, or dry products such as flour, sugar, coffee, spices, cereals, or food grains.

- Pharmaceutical industry: Transporting powdered pharmaceutical ingredients, tablets, and drug manufacturing materials without affecting product quality.

- Chemical industry: Pneumatic systems also help transport corrosive, flammable, or moisture-sensitive materials without risk.

- Mining and mineral processing industry: Transporting minerals such as coal, rock, ore, or grains from mining sites to processing plants.

- Plastic and rubber industry: Helps minimize exposure to air and avoid damage or breakage of plastic granules during production.

In short, pneumatic conveyor systems not only provide high efficiency in material transportation but also play an important role in optimizing production processes, minimizing pollution and improving safety in many different industries.

How is the Pneumatic Conveyor System used in various industries?

How to Choose the Right Pneumatic Conveyor System

Selecting the right pneumatic conveyor system requires balancing performance, cost, and operational needs.

A systematic evaluation ensures long-term efficiency.

- Define process requirements: Identify material type, throughput, and distance to determine suitable conveying method.

- Evaluate system scalability: Choose designs that allow future expansion or integration with automation upgrades.

- Work with experienced system designers: Professional engineering support reduces risk and improves system reliability.

Where to buy a reputable automatic Pneumatic conveyor system?

If you are uncertain about where to purchase a Pneumatic conveyor system, DNC Automation is an excellent option for you. Many customers have trusted DNC to provide automation solutions in the production process and have had positive experiences because:

- DNC is a leading technology, automation, and engineering company in Malaysia with over 15 years of experience in the field of automation

- System integration machinery, Internet of Things (IoT), Industry 4.0, and WinCC Scada System

- Diverse designs and sizes are suitable for many domestic and foreign houses. The equipment is 100% genuine and imported from Malaysia.

Please contact us via the hotline below if you have any questions about the product, we are happy to answer you!

- 19 views

- 0 Comment

Recent Comments