Automated Storage & Retrieval System (ASRS)

Moving pallets and packages around your warehouse is not always easy. We know that managing a warehouse has many challenges for distribution center managers like you. Some of these challenges include high labor costs, low productivity and efficiency, and high safety risks for employees.

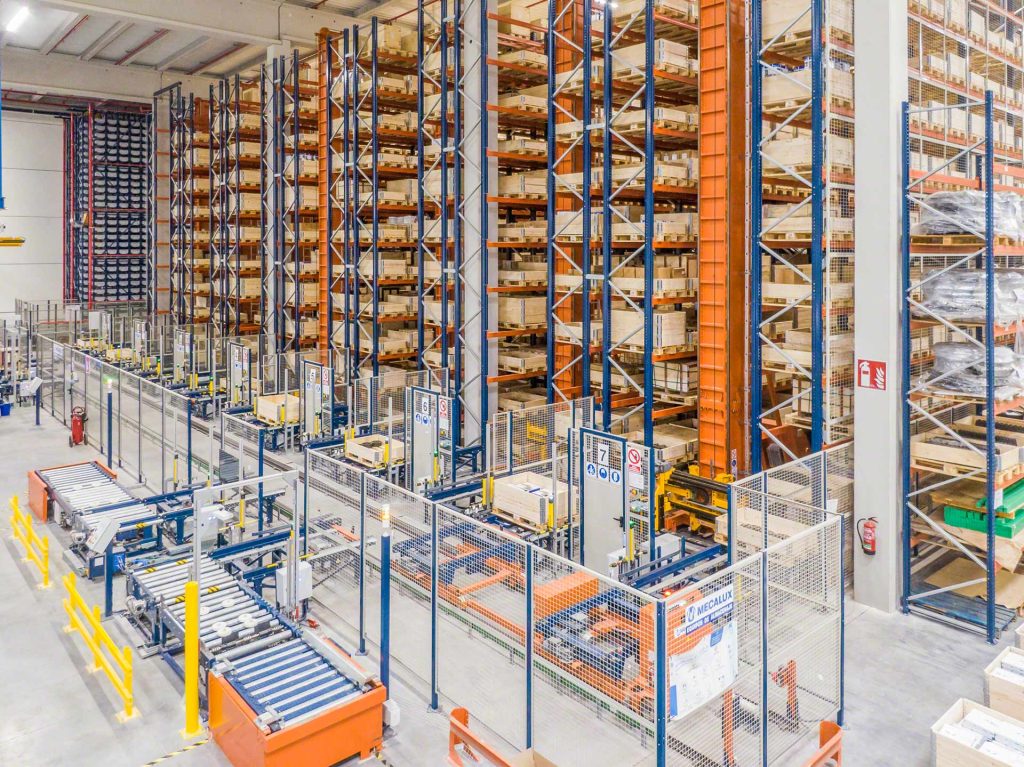

To overcome these challenges, our clients have success with automated storage and retrieval systems or ASRS. Currently, more than 10% of warehouses in the US use automated warehousing equipment. What about yours?

But does your warehouse really need an automated warehouse system? How can they help your warehouse optimization efforts? Well, let’s learn what ASRS is, its use cases, its benefits, and more.