Why should businesses choose Scraper Conveyor for production lines?

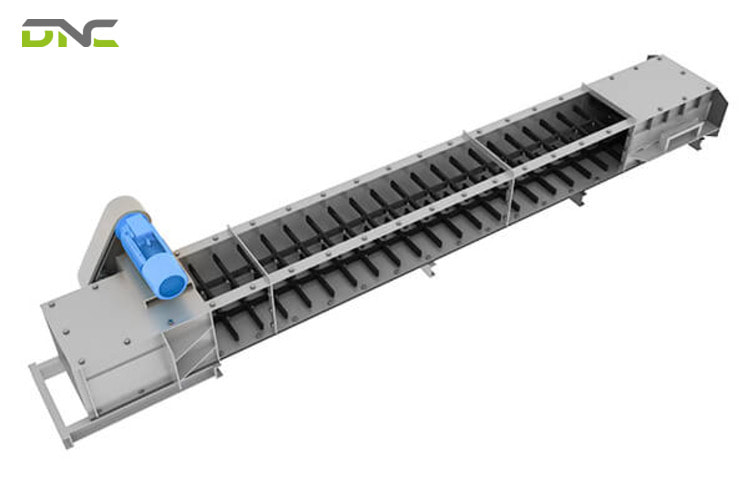

Scraper Conveyor is a conveyor solution designed to transport solid materials in harsh industrial environments, with a transport capacity of up to 100 tons per hour. With conveyor lengths of up to 100 meters and widths ranging from 300mm to 1500mm, this system is suitable for a wide range of applications from mining, food processing, to cement production and waste treatment. Join DNC Automation to learn more about the structure, benefits, applications and important technical parameters of this system in the article below.

What is a Scraper Conveyor?

A Scraper Conveyor is a conveyor in the automation industry, designed to move solid, granular, or powdery materials from one place to another in manufacturing, processing, or mining plants. This system works on the principle of using a scraper chain to push the material along a fixed track.

Technical specifications of Scraper Conveyor

- Size (length x width x height): 1500 x 500 x 1200 (mm)

- Load capacity: 500 kg/m to 5000 kg/m (depending on material type and capacity requirements)

- Speed: 0.1 m/s to 1 m/s

- Maximum slope: Usually from 15° to 45°

- Scraper size: 100 mm to 500 mm.

- Number of scrapers: 4 to 10 scrapers (depending on conveyor length and material load to be transported)

- Conveyor frame: Usually made of carbon steel, stainless steel or anti-corrosion alloys.

- Operating temperature: -10°C to 60°C

- Warranty: 12 months

How many parts does a Scraper Conveyor consist of?

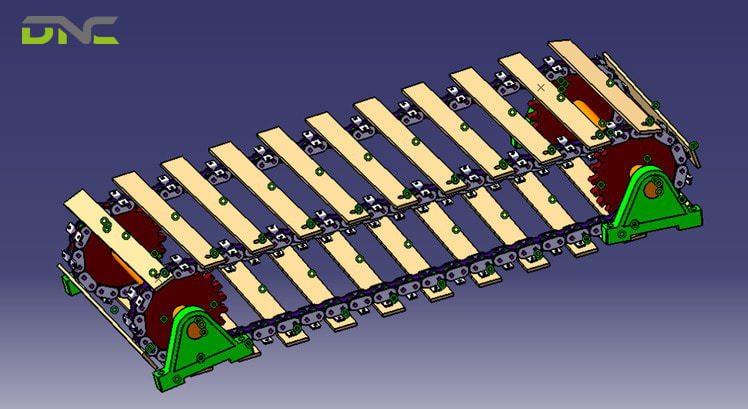

To better understand how a Scraper Conveyor works and is effective, it is important to understand the structure of the system. The structure of a Scraper Conveyor includes the following 4 main parts:

Conveyor frame

The frame is the main load-bearing part of the system, helping to keep the entire conveyor stable and sturdy during operation. The frame is usually made of steel or other durable materials, ensuring high durability in harsh production environments.

Drive chain or chain

The drive system of a Scraper Conveyor includes a chain or chain that moves the scrapers along the conveyor frame. These chains are designed to be sturdy enough to withstand heavy loads and operate continuously without damage.

Scraper

The scrapers are the parts that help transport materials along the conveyor. Rakes are typically attached to a chain or conveyor and can be designed as metal or hard plastic plates. These rakes push the material towards the conveyor outlet.

Guide Rails

Guide rails help guide the chain or conveyor accurately during operation. The rails can be made of steel or hardened materials to ensure accuracy and stability.

In addition to the main parts on the Scraper Conveyor, there are other supporting parts such as: Motor & Reducer, control system, safety system.

The structure of a Scraper Conveyor includes the following 4 main parts: Conveyor frame, Drive chain or chain, Scraper, Guide Rails

What are the benefits of using Scraper Conveyor in the factory?

Using Scraper Conveyor in the factory brings many outstanding benefits to help optimize the production and operation process.

- Efficient in transporting materials: Scraper conveyors are capable of transporting solid materials, powders, granules, or materials with special properties such as wet or sticky.

- Reduce operating costs: By minimizing manual steps and automating the transport process, Scraper Conveyor helps reduce labor costs and increase work efficiency.

- Reduce risks and improve labor safety: Automating the transport process helps minimize human intervention in dangerous or heavy steps, thereby improving the safety level in the factory and minimizing the risk of work accidents.

- High durability: Scraper Conveyor can operate in harsh environmental conditions such as high temperature, high humidity, or environments with abrasive materials.

- Increased Productivity: Scraper Conveyor is capable of operating 24/7 without major interruptions, helping to maintain stable production and increase overall productivity.

Using Scraper Conveyor in the factory brings many outstanding benefits to help optimize the production and operation process.

What are the considerations for selecting the right Scraper Conveyor for your plant?

When selecting the right Scraper Conveyor line for your plant, there are several important factors to consider to ensure operational efficiency and cost optimization. Here are some of the factors to consider:

- Type of material to be conveyed: Each type of material has different characteristics in terms of size, weight, moisture, and chemical properties, so it is necessary to choose a Scraper Conveyor that is capable of handling that material efficiently.

- Load capacity and capacity: Determining the volume of material to be conveyed in an hour or day will help you choose a system with the right capacity.

- Compatibility with other systems: The Scraper Conveyor system needs to be compatible with other equipment in the plant’s production line, such as automation, control and monitoring systems, to ensure synchronization during operation.

- Speed and performance: Material transport speed is an important factor to ensure the conveyor operates efficiently and without interruption. Depending on production needs, you can choose a conveyor with a fast or stable speed.

- Maintenance costs and service life: It is necessary to choose a product with high durability, easy maintenance and replacement of components when needed.

What are the considerations for selecting the right Scraper Conveyor for your plant?

Where to buy a reputable automatic Scraper conveyor?

If you are uncertain about where to purchase a Scraper conveyor, DNC Automation is an excellent option for you. Many customers have trusted DNC to provide automation solutions in the production process and have had positive experiences because:

- DNC is a leading technology, automation, and engineering company in Malaysia with over 15 years of experience in the field of automation

- System integration machinery, Internet of Things (IoT), Industry 4.0, and WinCC Scada System

- Diverse designs and sizes are suitable for many domestic and foreign houses. The equipment is 100% genuine and imported from Malaysia.

Please contact us via the hotline below if you have any questions about the product, we are happy to answer you!

- 6 views

- 0 Comment

Recent Comments