Overview

In modern manufacturing, jigs and fixtures play a crucial role in ensuring precision, consistency, and efficiency across production processes. These specialized tools are essential for maintaining accuracy and repeatability in the machining and assembly of interchangeable components — especially in high-volume industries such as automotive, aerospace, and electronics.

While both are designed to enhance productivity and reduce errors, their functions differ slightly:

- Jigs serve as guides for machining tools, ensuring that each operation is performed accurately and uniformly.

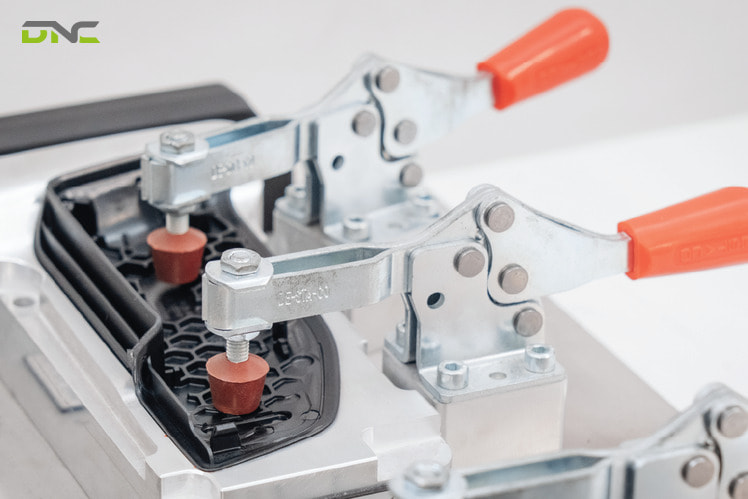

- Fixtures hold and secure the workpiece firmly in place during machining, providing stability and precision.

How DNC Automation Delivers Custom Jigs and Fixtures?

At DNC Automation, we specialize in the design, manufacturing, and installation of customized jigs and fixtures tailored to each client’s production requirements. With a strong focus on precision engineering and process optimization, DNC ensures every solution meets the highest standards of accuracy, durability, and efficiency.

Our implementation process typically includes the following key stages:

- Consultation & Requirement Analysis – Understanding client needs, component specifications, and production workflow to determine the most effective jig and fixture solution.

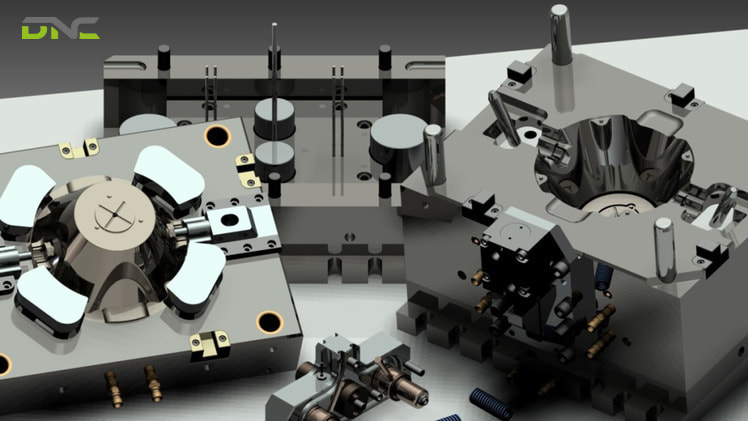

- 3D Design & Simulation – Using advanced CAD/CAM software to create detailed designs and simulate performance for maximum accuracy and functionality.

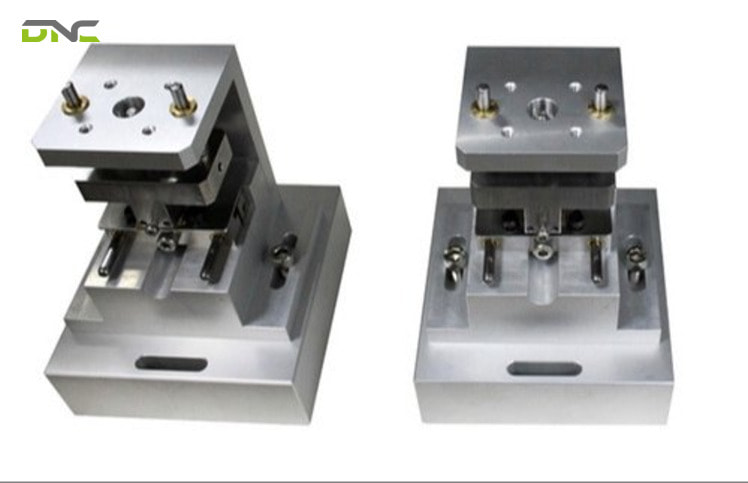

- Fabrication & Precision Testing – Manufacturing with state-of-the-art CNC machinery and verifying dimensional accuracy through rigorous testing and inspection.

- Installation & After-Sales Support – On-site setup, operator training, and regular maintenance services to ensure long-term reliability and performance.

With an experienced team of engineers and modern machining equipment, DNC Automation provides a complete, end-to-end solution that enhances manufacturing efficiency and product quality.

DNC Automation Delivers Custom Jigs and Fixtures

Key Benefits of Using DNC’s Custom Jigs and Fixtures

At DNC Automation, each solution is engineered to help automotive and industrial manufacturers in Malaysia achieve consistent quality and long-term productivity gains. Here are 6 benefits of Jigs and Fixtures:

- High Precision and Repeatability: DNC’s jigs and fixtures ensure accurate positioning and consistent results, reducing human error and maintaining quality across every production batch.

- Faster Production Cycles: Custom designs help minimize setup time and streamline operations, allowing manufacturers to achieve higher throughput and shorter lead times.

- Cost and Waste Reduction: By improving accuracy and minimizing rework, DNC’s solutions lower material waste and overall production costs.

- Enhanced Operator Safety: Secure clamping and stable setups reduce manual handling, minimizing the risk of accidents during machining or welding.

- Customization and Flexibility: Each jig and fixture is tailored to the client’s specific parts and processes, adaptable for future product changes or upgrades.

- Longer Tool and Machine Life: Stable, precise tooling reduces vibration and wear, extending the lifespan of cutting tools and machinery.

Benefits of Using DNC’s Custom Jigs and Fixtures

Frequently Asked Questions About Jigs and Fixtures

Here are some common questions manufacturers in Malaysia often ask about jigs and fixtures, beyond the main topics covered in our article:

- What is the difference between a standard fixture and a custom fixture?

Standard fixtures are off-the-shelf solutions suitable for general tasks and low-volume production. Custom fixtures, however, are specifically designed for unique parts, production processes, and tolerances. DNC Automation specializes in creating custom solutions that perfectly match the client’s requirements, ensuring maximum efficiency and accuracy.

2. How long does it take to design and produce a custom jig or fixture?

The timeline depends on the complexity of the part, material selection, and production volume. Simple fixtures can be designed and fabricated within a few weeks, while highly specialized jigs with multiple components or tight tolerances may take several months.

DNC follows a structured workflow including requirement analysis, 3D design, simulation, fabrication, and testing, ensuring on-time delivery without compromising quality.

3. Can jigs and fixtures be used across different production lines?

Typically, jigs and fixtures are designed for a specific part or process. However, DNC offers modular and adjustable designs that can be adapted to multiple product variants or different production lines, providing flexibility for manufacturers who need to scale or diversify operations.

4. How do jigs and fixtures impact product quality?

The main benefit of using precision jigs and fixtures is the enhanced accuracy and repeatability. By holding parts securely and guiding tools precisely, human error is minimized.

This leads to fewer defects, higher consistency, and ensures that every component meets the strictest industry standards, particularly important in automotive, aerospace, and electronics manufacturing.

5. What materials are typically used to manufacture jigs and fixtures?

Material choice depends on the application and required durability. Common options include hardened steel for heavy-duty machining, aluminum for lightweight components, and composite materials for specific applications requiring corrosion resistance or reduced weight. DNC selects materials carefully to balance longevity, cost, and precision.

6. Do jigs and fixtures require maintenance?

Yes. Regular maintenance, such as cleaning, inspection, and recalibration, is crucial to ensure long-term accuracy and prevent wear from affecting production quality. DNC provides guidance and support for maintenance routines, helping clients maximize the lifespan of their tools.

Frequently Asked Questions About Jigs and Fixtures

Why Choose DNC Automation for Jigs and Fixtures in Malaysia?

Choosing the right partner for jigs and fixtures is crucial for precision manufacturing. DNC Automation stands out as a trusted provider in Malaysia, offering comprehensive solutions backed by extensive experience and technical expertise.

- DNC is a leading technology, automation, and engineering company in Malaysia with over 15 years of experience in the field of automation

- System integration machinery, Internet of Things (IoT), Industry 4.0, and WinCC Scada System

- Diverse designs and sizes are suitable for many domestic and foreign houses. The equipment is 100% genuine and imported from Malaysia.

Please contact us via the hotline below if you have any questions about the product, we are happy to answer you!

DNC Automation Malaysia