Overview About Automatic Weight And Packing Machine

An automatic weight packing machine is a precision-driven system designed to weigh, fill, and seal products like rice, snacks, sugar, and fertilizers efficiently. Using load cells and digital control systems, it ensures each pack meets exact weight specifications while minimizing waste and maximizing productivity. Ideal for Malaysia’s growing manufacturing and food industries, these machines play a vital role in achieving consistent product quality, optimizing labor costs, and supporting the nation’s Industry 4.0 automation goals.

How Does It Work?

The process involves a series of integrated steps designed for accuracy and efficiency:

- Feeding – The raw product is transferred via a feeder or conveyor into the weighing unit.

- Weighing – The machine’s load cells calculate the exact weight according to the preset value.

- Filling – Once the correct weight is reached, the product is released into a bag, pouch, or container.

- Sealing – Heat or impulse sealing systems close the package securely.

- Labeling and Discharge – The finished product is labeled and discharged onto the conveyor for the next process.

How Does It Work?

What Types of Automatic Weight Packing Machines?

Different machine designs suit various industries and production requirements.

Linear Weigher Packing Machine

Best suited for granules, powders, fertilizers, and detergents. It features multiple linear feeding channels that weigh and fill products sequentially, offering excellent accuracy for mid-speed operations.

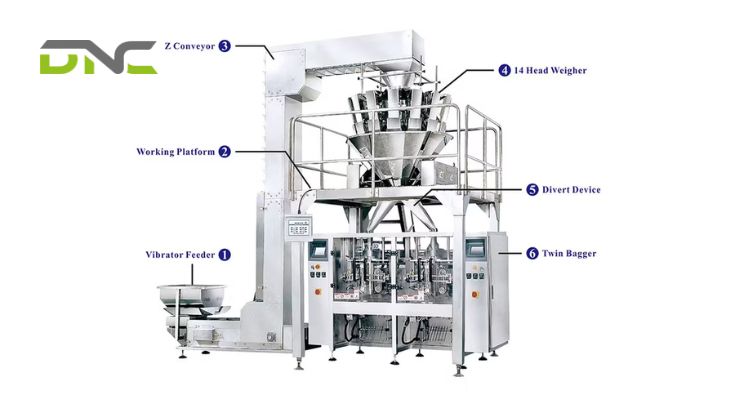

Multihead Weigher Packing Machine

Widely used in the food industry for snacks, frozen foods, and coffee. It uses 10 or 14 heads that combine weight readings to achieve exact target weights. The result: faster throughput and consistent packaging quality.

Semi vs. Fully Automatic Systems

Semi-automatic machines still require operator involvement for bag placement or sealing, while fully automatic systems integrate conveyors, sealers, and labelers for continuous, hands-free packaging. Choosing between them depends on production volume, budget, and labor availability.

Benefits of Using Automatic Weight Packing Systems

Automation delivers measurable returns in performance, consistency, and operational cost reduction.

- High Accuracy and Reduced Product Loss: Load cells and digital controllers ensure each pack meets the desired weight. This reduces product giveaway and material waste – a critical factor for manufacturers handling expensive raw materials.

- Improved Efficiency and Productivity: Automatic systems maintain consistent packaging speeds, minimizing downtime between batches. Servo motors and synchronized conveyors boost cycle time efficiency, helping companies achieve higher throughput and improved OEE scores.

- Cost and Labor Optimization: By automating weighing and sealing, companies can operate longer hours with fewer workers. This not only mitigates Malaysia’s ongoing labor shortage but also ensures consistent quality output and a faster ROI.

- Enhanced Hygiene and Product Safety: Automatic systems eliminate manual contact, maintaining food-grade safety and cleanliness. Stainless-steel construction and dust extraction systems meet GMP and HACCP requirements for hygiene compliance.

- Data Traceability and Process Control: With integrated PLC and SCADA systems, manufacturers can log weight accuracy, sealing temperatures, and cycle counts. This digital traceability supports audits, quality control, and continuous improvement initiatives.

Benefits of Using Automatic Weight Packing Systems

Industrial Applications Automatic Weight Packing Machine in Malaysia

Automatic weight packing machines are adaptable across multiple sectors:

- Food and Beverage Industry: Used for rice, coffee, spices, and frozen goods. Multihead weighers ensure accuracy and minimize waste, supporting Malaysia’s fast-growing packaged food market.

- Agriculture and Fertilizer: Bulk bagging of seeds, fertilizers, and animal feed. Heavy-duty systems handle coarse materials efficiently, improving productivity for agro-based industries.

- Chemical and Construction Materials: Perfect for powders, detergents, cement, and sand. Machines are equipped with dust control and anti-corrosion seals for safe handling of industrial materials.

Why Choose DNC Automation for Weight Packing Solutions?

With over a decade of experience in factory automation and packaging integration, DNC Automation stands out as Malaysia’s trusted partner for custom-designed weight packing systems.

DNC Automation – The best choice for weight packing solutions?

- Turnkey Solutions: From design, simulation, installation to after-sales support.

- Integration Expertise: Seamless link between PLC, HMI, conveyors, and SCADA systems.

- Local Support: Fast service response and spare parts availability across Malaysia.

Partnering with DNC Automation ensures your production line operates with precision, efficiency, and full Industry 4.0 readiness.

- 0 views

- 0 Comment

Recent Comments