Automatic Handling and Packaging Lines | A Complete Guide for Manufacturers

As Malaysia accelerates toward Industry 4.0, manufacturers are seeking smarter, faster, and more consistent production solutions. Automatic handling and packaging lines integrate robotics, conveyors, and intelligent control systems to improve efficiency, quality, and compliance in modern factories.

What Are Automatic Handling and Packaging Lines?

Automatic handling and packaging lines form the backbone of modern manufacturing — connecting every stage from material movement to final product packaging through synchronized automation and control.

What Are Automatic Handling and Packaging Lines?

How Automatic Handling and Packaging Lines Work

To understand their value, it’s essential to see how each process stage — from feeding to palletizing – operates under centralized control.

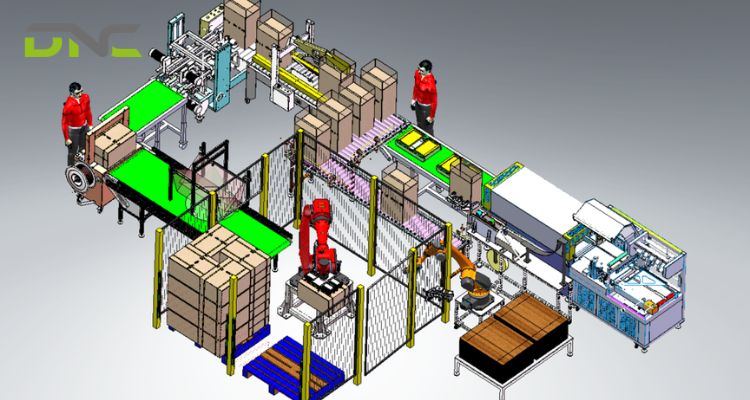

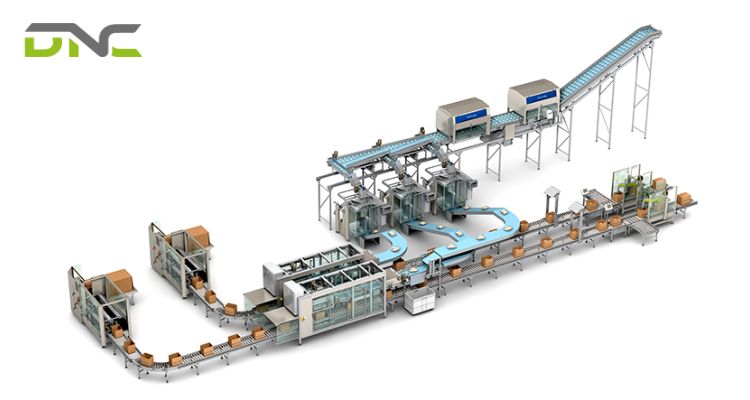

Workflow Overview – From Product Feeding to Palletizing

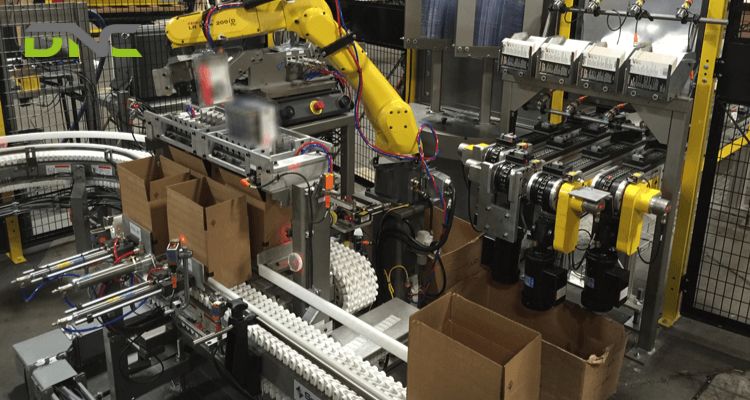

The process begins with feeding conveyors transporting items to pick-and-place robots or bagging and sealing machines. Products are then transferred to carton erectors and wrapping machines before ending at automated palletizers for stacking and dispatch. Every stage communicates through smart sensors and digital control, ensuring continuous flow and zero bottlenecks.

Control and Integration with Factory Automation

Modern packaging lines rely on tight integration between PLC, HMI, and SCADA systems. Software such as Siemens TIA Portal, Omron Sysmac, and Allen-Bradley platforms — often implemented by DNC Automation Malaysia enable real-time data visualization, production tracking, and remote troubleshooting. These control layers form the foundation of a smart factory aligned with Malaysia’s Industry 4.0 roadmap.

How Automatic Handling and Packaging Lines Work

What are the benefits of Automated Handling and Packaging Solutions

Investing in automation brings tangible advantages from production speed to quality assurance and regulatory compliance.

Productivity and Efficiency Gains

Automated lines dramatically increase output while reducing downtime. With continuous 24/7 operation and minimal manual intervention, manufacturers achieve better packaging line efficiency, reduced labor costs, and faster ROI. This supports lean manufacturing and smart production principles widely promoted in Malaysia’s industrial automation roadmap.

Quality, Safety, and Compliance

Automation ensures every product is handled and packaged with uniform precision. Integrated inspection systems detect errors early, enhancing safety and meeting HACCP, ISO 9001, and GMP Malaysia standards. Automated traceability functions also help manufacturers maintain compliance with the Department of Standards Malaysia for food and pharmaceutical products.

What Are the Applications of Automatic Handling and Packaging Lines?

Across Malaysia’s industrial landscape, automation transforms operations in F&B, pharmaceuticals, logistics, and electronics, all benefiting from speed, hygiene, and accuracy.

Food and Beverage Industry

Major producers such as Nestlé Malaysia, F&N, and Coca-Cola Malaysia deploy automated packaging systems for consistent filling, sealing, and labeling. Hygienic food packaging automation and beverage bottling lines ensure freshness and compliance while reducing wastage, a critical advantage for ASEAN food exporters.

Pharmaceutical and Healthcare Sector

In the pharmaceutical industry, automation guarantees precision and safety. Companies like Duopharma Biotech and Pharmaniaga use blister packing automation, cleanroom handling systems, and traceability solutions to meet GMP and medical packaging standards. Automation minimizes contamination risks and improves batch consistency.

Electronics, Logistics, and E-commerce

For electronics and logistics sectors, automation enhances material handling and packaging flexibility. Flex Malaysia, DHL Supply Chain, and Shopee Fulfillment Centers integrate automated sorting systems, AGVs, and robotic handling for faster order fulfillment and reduced errors.

What Are the Applications of Automatic Handling and Packaging Lines?

Technology Trends Shaping Packaging Automation in Malaysia

Emerging innovations like IoT, AI, and robotics are redefining how Malaysian factories handle packaging automation and quality control.

- Integration with Industry 4.0 and Smart Factories: Malaysia’s Smart Factory 4.0 initiative, supported by MIDA and the Malaysia Productivity Corporation (MPC), promotes data-driven manufacturing. Smart packaging systems connected via IoT sensors and AI analytics enable predictive maintenance, real-time monitoring, and optimized production efficiency.

- Robotics, Vision Systems, and Machine Learning: The latest generation of automation integrates collaborative robots (cobots), AI-based vision inspection, and autonomous guided vehicles (AGVs). These technologies enable faster defect detection, safer human-robot collaboration, and autonomous material movement.

Technology Trends Shaping Packaging Automation in Malaysia

Why DNC Automation is The Best Choice for Handling and Packaging Lines

When evaluating a partner, prioritize experience, customization capabilities, and after-sales support. A reliable automation system integrator provides turnkey packaging solutions, on-site service, and technical expertise in Malaysia’s manufacturing standards. Local support ensures faster troubleshooting and smoother upgrades over time.

DNC Automation stands among Malaysia’s leading industrial automation experts, specializing in robotic packaging and material handling systems. With deep experience in PLC, HMI, and SCADA integration, DNC delivers customized, end-to-end packaging solutions designed for long-term reliability and Industry 4.0 readiness.

Automatic handling and packaging lines are transforming Malaysia’s manufacturing landscape, improving productivity, product quality, and compliance with global standards. By partnering with an experienced integrator like DNC Automation, businesses can accelerate their transition to smart, data-driven factories and achieve sustainable growth under Industry 4.0.

- 3 views

- 0 Comment

Recent Comments