Turntable Conveyor: Smart Solution for Automated Flow

In modern automated facilities, inefficient material flow is one of the biggest challenges affecting productivity, space utilization, and operational costs. Production bottlenecks, limited floor space, and complex conveyor layouts often make it difficult to achieve smooth transitions between processes. This is where businesses begin searching for smarter conveyor solutions that can redirect products without stopping the entire system. A turntable conveyor addresses these demands by enabling controlled direction changes while maintaining workflow continuity. As automation becomes more complex, turntable conveyors play a critical role in creating flexible, efficient, and scalable material handling systems.

What Is a Turntable Conveyor?

A turntable conveyor is a rotary material handling device designed to change the direction of products, pallets, or containers within an automated conveyor system. Instead of transferring loads manually or using complex multi-line conveyors, a turntable rotates to align items with different conveyor paths. This allows smooth redirection at angles such as 90°, 180°, or even 360°.

Commonly used in automated production lines and warehouses, turntable conveyors help optimize layout design, reduce manual intervention, and maintain consistent material flow without disrupting upstream or downstream processes.

How Does a Turntable Conveyor Work?

Understanding how a turntable conveyor operates helps system designers and operators appreciate its value in automation environments. The working principle is simple, yet highly effective when integrated correctly.

A turntable conveyor works by receiving a load on its rotating platform and turning it to a predefined angle before releasing it onto another conveyor line.

- Load Detection and Positioning: Sensors detect the incoming product or pallet and ensure it is correctly positioned at the center of the turntable. This accuracy prevents misalignment and ensures safe rotation, especially for heavy or fragile loads.

- Controlled Rotation Mechanism: The turntable rotates using a motor-driven system, often controlled by a PLC. The rotation angle is pre-programmed, allowing precise directional changes without stopping the overall conveyor flow.

- Seamless Transfer to Next Conveyor: Once aligned, the load is transferred smoothly to the next conveyor. This minimizes transfer time and maintains consistent throughput across the automated system.

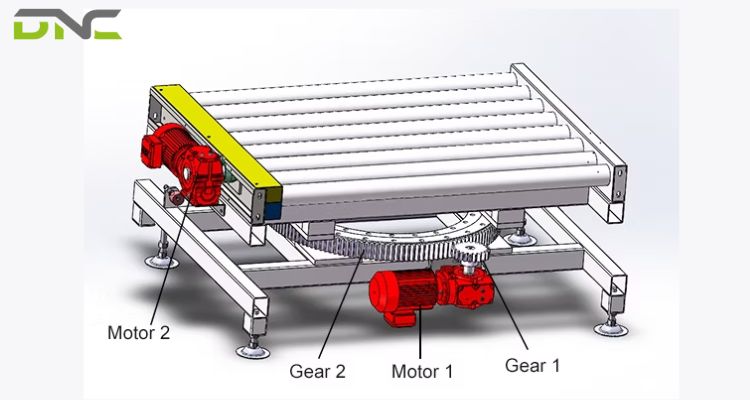

Key Components of a Turntable Conveyor System

Each turntable conveyor is built from several essential components that work together to ensure smooth, reliable operation within automated environments.

- Rotary Platform: The platform supports the load during rotation. It is designed to handle specific weight capacities and surface requirements depending on the application.

- Drive Motor and Gear System: This component provides the torque required to rotate the platform accurately. Proper motor sizing is critical for performance and durability.

- Control System and Sensors: Integrated sensors and control panels ensure precise positioning, rotation angle control, and safe operation within the conveyor system.

- Safety Features: Guards, emergency stops, and interlocks protect operators and equipment, especially in high-speed or heavy-load applications.

Common Applications of Turntable Conveyors

Turntable conveyors are widely used across industries where automation, accuracy, and layout flexibility are critical to daily operations.

- Automated Production Lines: In manufacturing environments, turntable conveyors redirect products between processing stations without manual handling, improving efficiency and consistency.

- Warehouse and Distribution Systems: They enable efficient routing of pallets and cartons to different storage, sorting, or packing lines, reducing congestion and space requirements.

- Packaging and Palletizing Lines: Turntables allow products to be oriented correctly before packaging or palletizing, ensuring smooth downstream operations.

Benefits of Using a Turntable Conveyor in Automation

Beyond simple direction changes, turntable conveyors offer several operational advantages that make them a preferred choice in modern automated systems.

- Optimized Space Utilization: Turntable conveyors reduce the need for long conveyor runs or complex transfer mechanisms, making them ideal for facilities with limited space.

- Improved Workflow Efficiency: By enabling smooth directional changes, they help maintain continuous flow and reduce system downtime.

- Reduced Manual Handling: Automation minimizes human intervention, lowering labor costs and improving workplace safety.

- Flexible System Design: Turntable conveyors make it easier to adapt conveyor layouts as production needs change.

Turntable Conveyor vs Other Conveyor Solutions

Choosing the right conveyor solution depends on system requirements, load type, and layout complexity. Comparing options helps decision-makers make informed choices.

| Feature | Turntable Conveyor | Transfer Conveyor | Straight Conveyor |

| Direction Change | Excellent | Moderate | Limited |

| Space Efficiency | High | Medium | Low |

| Automation Integration | High | Medium | High |

| System Flexibility | High | Medium | Low |

| Ideal Use Case | Multi-direction routing | Line merging | Linear transport |

Key Considerations When Selecting a Turntable Conveyor

Sapo paragraph

Selecting the right turntable conveyor requires careful evaluation of system requirements to ensure long-term performance and reliability.

- Load Type and Weight: The conveyor must be designed to handle the maximum load safely, including size, weight, and stability during rotation

- Rotation Angle Requirements: Understanding whether the application requires 90°, 180°, or full rotation helps determine the correct design.

- Integration with Existing Systems: Compatibility with current conveyors, controls, and automation software is essential for seamless operation.

- Maintenance and Lifecycle Costs: Well-designed turntable conveyors reduce maintenance needs and offer better long-term value.

Why Is a Turntable Conveyor Important for Modern Automation?

As automation systems become more advanced, the need for efficient and flexible material routing continues to grow.

- Supports Scalable Automation: Turntable conveyors allow systems to expand without major layout changes.

- Enhances Process Control: Precise rotation and positioning improve consistency and reduce errors.

- Improves Overall System Reliability: Fewer transfer points mean fewer failure risks and smoother operations.

Is a Turntable Conveyor the Right Choice for Your Automation System?

A turntable conveyor is an ideal solution when your system requires flexible routing, space efficiency, and seamless integration into automated workflows. Whether used in production lines, warehouses, or packaging systems, it helps optimize performance while supporting future scalability. Partnering with an experienced automation provider ensures the solution is designed, integrated, and maintained correctly for long-term success.

DNC Automation – Your Trusted Partner for Turntable Conveyor Solutions

DNC Automation is a trusted partner for designing and delivering reliable turntable conveyor solutions that align with your automation goals. With strong technical expertise and a system-focused approach, DNC Automation helps businesses improve efficiency, reduce operational challenges, and build scalable material handling systems.

Contact us now to discuss your automation requirements and discover how a customized turntable conveyor solution can enhance your operations.

- 0 views

- 0 Comment

Recent Comments