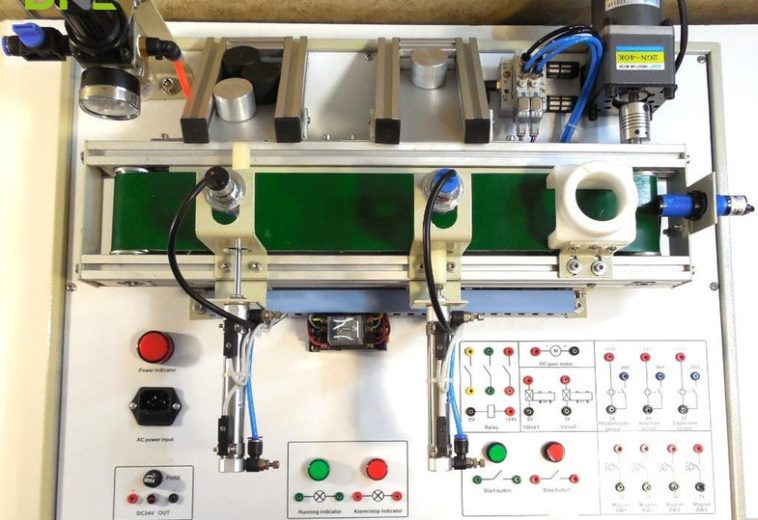

PLC Conveyor Systems: Control Logic, Components, Safety & Automation Benefits

PLC conveyor systems are widely used in modern industrial environments where conveyors must operate safely, reliably, and in coordination with other equipment. By using a programmable logic controller, conveyor operation can be precisely controlled through software-defined logic rather than manual or relay-based control. What is a PLC conveyor system? As conveyor systems grow in size..

Read more- 0 views

- 0 Comment

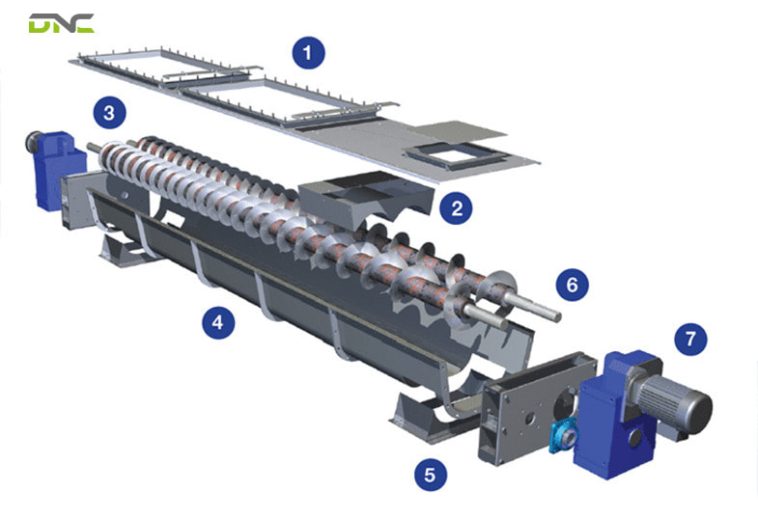

Screw Conveyor Feeder Explained: Types, Design, Advantages & Applications

Screw conveyor feeders are used in industrial processes to deliver bulk materials at a controlled and consistent rate into downstream equipment. Designed specifically for feeding rather than simple conveying, screw feeders play an important role in stabilizing material flow and supporting reliable process operation. This article explains how screw conveyor feeders work, the common types..

Read more- 3 views

- 0 Comment

Aluminium Profile Conveyor Systems: Modular Design for Automated Production Lines

In modern automated manufacturing, conveyor systems must be flexible, clean, and easy to integrate with automation equipment. Aluminium profile conveyors are designed to meet these requirements by combining modular aluminium extrusion frames with various conveying mechanisms, enabling efficient material handling in dynamic production environments. What Is an Aluminium Profile Conveyor? An aluminium profile conveyor is..

Read more- 0 views

- 0 Comment

Modular Conveyor Systems: Design, Flexibility, Applications & Key Considerations

Modular conveyor systems are increasingly used in modern manufacturing and automation environments where flexibility, scalability, and fast reconfiguration are essential. Built from standardized and interchangeable modules, modular conveyors allow production lines to be easily adapted to changing products, layouts, and throughput requirements. What is a modular conveyor and how does it differ from traditional conveyors?..

Read more- 0 views

- 0 Comment

Green Conveyor Belt Systems: Energy-Efficient and Sustainable Material Handling

In modern manufacturing, sustainability and energy efficiency are becoming key priorities in material handling system design. Green conveyor belts are developed to reduce energy consumption, minimize environmental impact, and support long-term operational efficiency, while still meeting the performance demands of automated production lines. What Is a Green Conveyor Belt? A green conveyor belt is a..

Read more- 1 views

- 0 Comment

Mobile Conveyor: A Detailed Guide to Flexible Material Handling Systems

Mobile conveyors are widely used in industries that require flexible, temporary, or frequently changing material handling layouts. Unlike fixed conveyor systems, mobile conveyors are designed to be easily repositioned, allowing materials to be transported efficiently across different locations without permanent installation. What is a mobile conveyor and how is it different from a fixed conveyor?..

Read more- 1 views

- 0 Comment

Transfer Conveyor Systems: Design, Types, Benefits, and Automation Integration

In modern automated production lines, products often need to move between conveyors, change direction, or connect multiple processes. Transfer conveyors ensure smooth, controlled product movement at these transition points, helping maintain stable flow, reduce bottlenecks, and support flexible, automated material handling systems. What Is a Transfer Conveyor? A transfer conveyor is a specialized conveyor system..

Read more- 1 views

- 0 Comment

Conveyor Belt Scales Explained: Principles, Accuracy, Applications & Automation Value

Conveyor belt scales play a critical role in industries that handle bulk materials through continuous processes. By measuring material weight directly on a moving conveyor, these systems provide real-time insight into material flow, throughput, and production performance without interrupting operations. This article offers a detailed technical overview of conveyor belt scales, explaining how they work,..

Read more- 0 views

- 0 Comment

Screw auger conveyor – High-quality and authentic 2026

Choosing the right screw conveyor manufacturer is not just about buying equipment—it’s about ensuring long-term operational efficiency, product consistency, and minimal downtime. Many industrial buyers struggle with conveyors that clog, wear out too quickly, or fail to match real production requirements. Whether you handle powders, granules, or bulk materials, a poorly designed screw conveyor can..

Read more- 81 views

- 0 Comment

Chip Conveyor Systems: Types, Advantages, and CNC Machining Applications

A chip conveyor is an essential auxiliary system in CNC machining, designed to remove metal chips efficiently and continuously from the cutting area. By automating chip evacuation and coolant recovery, chip conveyors help improve machine uptime, tool life, and overall production efficiency in modern manufacturing environments. What Is a Chip Conveyor? A chip conveyor is..

Read more- 10 views

- 0 Comment

Recent Comments