Conveyor Dorner Solutions for Precision Automation

In modern automated production lines, even small inefficiencies in material handling can lead to downtime, quality issues, and rising operational costs. Many manufacturers struggle with conveyors that lack precision, flexibility, or compatibility with automation systems. This is where conveyor Dorner solutions become highly relevant. Designed for accuracy, compact layouts, and seamless integration, Dorner conveyors address the growing demand for reliable and scalable automation.

Understanding how these conveyors work, their types, and where they perform best helps businesses make informed decisions that support productivity, consistency, and long-term operational efficiency.

What Is a Conveyor Dorner?

A conveyor Dorner refers to a precision conveyor system manufactured by Dorner, widely used in automated industrial environments. These conveyors are engineered to move products with high accuracy, controlled speed, and repeatable positioning. Unlike conventional conveyors, Dorner systems are designed with modular construction, compact frames, and flexible configurations that allow easy integration into automation lines.

They are commonly applied in assembly, packaging, inspection, and robotic cells where precision and space efficiency are critical. Their adaptability makes them suitable for both simple material transfer and complex automated workflows.

Key Features of Conveyor Dorner Systems

Conveyor Dorner systems are engineered to meet the demands of precision-driven automation environments. Their design focuses on accuracy, flexibility, and seamless system compatibility, making them suitable for applications where consistent product movement and controlled handling are essential.

- High Precision and Repeatability: Conveyor Dorner systems provide accurate product positioning with consistent motion control. This level of repeatability is critical in automated assembly, inspection, and robotic applications where even small deviations can affect product quality and system performance.

- Modular and Space-Efficient Design: The modular construction allows conveyor Dorner systems to be easily configured or expanded as production requirements change. Compact frames make them ideal for installations with limited space while still maintaining high throughput and reliability.

- Automation-Ready Integration: These conveyors are designed to integrate smoothly with PLCs, sensors, vision systems, and robotic equipment. This reduces integration complexity and ensures synchronized operation across the entire automation line.

- Durable Construction for Continuous Operation: Conveyor Dorner systems are built with robust materials to withstand continuous industrial use. Their durability helps minimize mechanical wear, reduce maintenance frequency, and support stable long-term operation.

Common Types of Conveyor Dorner Systems

Different production needs require different conveyor configurations. Below are the most common types of conveyor Dorner systems, each suited to specific automation scenarios.

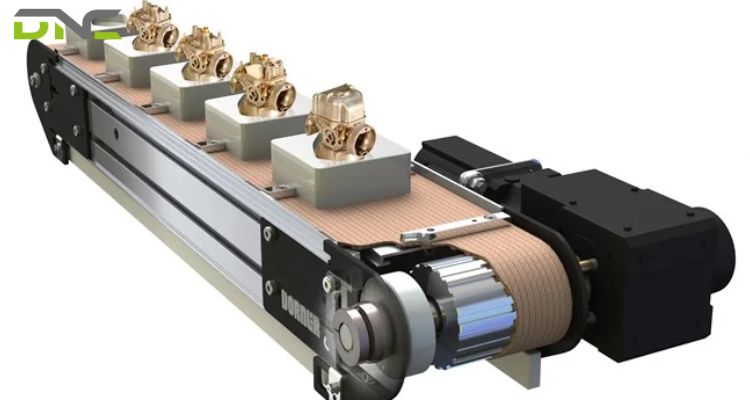

Belt Conveyors

Dorner belt conveyors are designed for smooth and continuous product movement.They are ideal for handling small to medium-sized items where gentle transport and precise positioning are required. These conveyors are widely used in assembly, inspection, and packaging lines due to their stable belt surface and consistent motion.

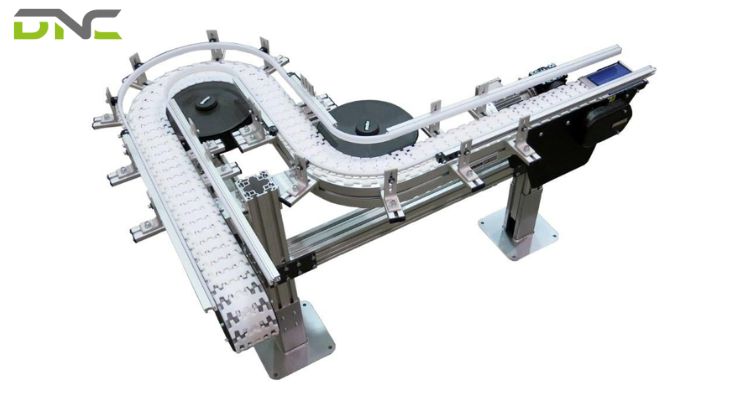

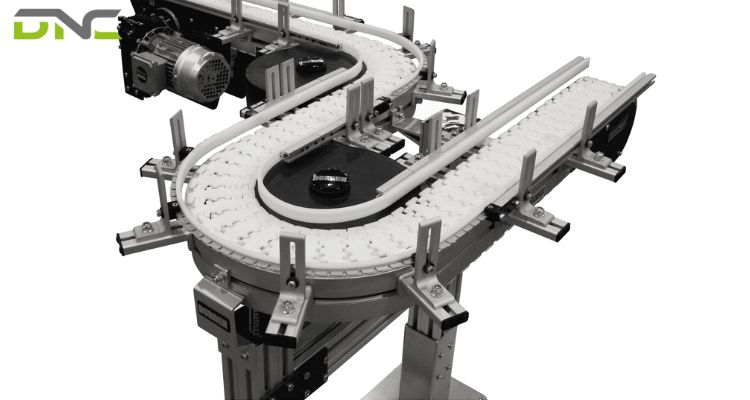

Modular Belt Conveyors

Modular belt Dorner conveyors use interlocking belt segments for durability and flexibility.They perform well in environments that require frequent cleaning, product accumulation, or curved layouts. The modular design allows easy maintenance and adaptation to changing production demands.

Precision Pallet Conveyors

These conveyors are designed for applications requiring exact part positioning.They are commonly used in automated assembly systems where pallets carry products through multiple workstations. High repeatability ensures accurate alignment for tools, robots, and inspection devices.

Flexible Automation Conveyors

Flexible Dorner conveyor systems support complex automation layouts. They can be integrated with lifts, transfers, and diverters to manage product flow across multiple levels or directions. This type is suitable for advanced automated production cells.

Industrial Applications of Conveyor Dorner Solutions

Conveyor Dorner systems are widely used across various industries due to their adaptability and precision.

Assembly Automation

In automated assembly lines, precise positioning is essential.

- Dorner conveyors maintain consistent spacing between products

- They support synchronized movement with robotic arms and tools

- This improves assembly accuracy and reduces cycle time

Packaging and Sorting Lines

Packaging operations demand reliability and flexibility.

- Conveyor Dorner systems handle different product sizes with minimal adjustment

- They support integration with labeling, weighing, and sorting equipment

- This results in smoother workflow and reduced bottlenecks

Electronics and Precision Manufacturing

Small components require careful handling.

- Dorner conveyors provide controlled movement to prevent damage

- Compact designs fit cleanroom and space-limited environments

- High accuracy supports inspection and quality control processes

Benefits of Using Conveyor Dorner in Automation

Implementing conveyor Dorner systems in automated production lines provides measurable operational advantages. These benefits directly impact productivity, system reliability, and overall process efficiency in modern manufacturing environments.

- Improved Production Efficiency: Conveyor Dorner systems ensure smooth and controlled material flow, reducing stoppages and delays. Consistent movement allows automation equipment to operate at optimal cycle times, improving overall line performance.

- Higher Process Accuracy: Accurate product positioning minimizes handling errors and reduces rework. This is especially valuable in precision manufacturing and automated assembly processes where quality consistency is a top priority.

- Reduced Downtime and Maintenance: The simplified mechanical design and modular components make maintenance faster and more predictable. This helps reduce unplanned downtime and keeps automated systems running reliably.

- Scalability for Future Automation Needs: Conveyor Dorner solutions can be expanded or reconfigured as production volumes increase. This scalability protects long-term investment and supports gradual automation growth without major system redesign.

Conveyor Dorner vs Traditional Conveyor Systems

Understanding the differences between Dorner conveyors and conventional conveyor systems helps clarify their value in automation projects.

| Comparison Criteria | Conveyor Dorner | Traditional Conveyors |

|---|---|---|

| Precision Control | High accuracy and repeatability | Limited positioning accuracy |

| Automation Integration | Designed for PLCs and robots | Often requires modification |

| Space Efficiency | Compact and modular frames | Larger and less flexible |

| Customization | High level of configuration | Limited standard options |

| Maintenance | Lower due to modular design | Higher due to mechanical complexity |

This comparison highlights why conveyor Dorner systems are often selected for automation-driven environments where precision and flexibility are non-negotiable.

Benefits of Using Conveyor Dorner in Automation

Implementing conveyor Dorner systems in automated production lines provides measurable operational advantages. These benefits directly impact productivity, system reliability, and overall process efficiency in modern manufacturing environments.

- Improved Production Efficiency: Conveyor Dorner systems ensure smooth and controlled material flow, reducing stoppages and delays. Consistent movement allows automation equipment to operate at optimal cycle times, improving overall line performance.

- Higher Process Accuracy: Accurate product positioning minimizes handling errors and reduces rework. This is especially valuable in precision manufacturing and automated assembly processes where quality consistency is a top priority.

- Reduced Downtime and Maintenance: The simplified mechanical design and modular components make maintenance faster and more predictable. This helps reduce unplanned downtime and keeps automated systems running reliably.

- Scalability for Future Automation Needs: Conveyor Dorner solutions can be expanded or reconfigured as production volumes increase. This scalability protects long-term investment and supports gradual automation growth without major system redesign.

Why Choose Conveyor Dorner Solutions from DNC Automation?

Selecting and integrating conveyor Dorner systems requires technical expertise and real-world automation experience. DNC Automation is a trusted partner that supports businesses throughout the entire automation journey.

- Proven experience in automation system integration

- Deep understanding of conveyor Dorner applications

- Customized solutions aligned with production goals

- Professional support from design to commissioning

By working with a knowledgeable partner, businesses can ensure that conveyor Dorner systems deliver maximum performance, reliability, and return on investment. Contact DNC Automation now to explore how conveyor Dorner solutions can be tailored to your automation needs and help optimize your production

- 9 views

- 0 Comment

Recent Comments