Conveyor Table: Ergonomic Assembly & Inspection Workstations for Malaysian Factories | DNC Automation

Conveyor Table — Ergonomic Workstation Integration for Malaysian Factory Assembly Lines

Conveyor tables are the intersection point between material flow and human work — the place where products arrive at the correct height, speed, and orientation for operators to assemble, inspect, label, or pack them without excessive reaching, bending, or manual lifting. Malaysian factories across the electronics, F&B, and automotive sectors still lose significant productivity to poorly designed workstations where operators reach above shoulder height to retrieve parts, bend below the knees to access components, and suffer the cumulative musculoskeletal injuries that account for a leading share of Malaysian manufacturing sick leave. A correctly specified conveyor table — whether a gravity roller station, powered belt worktop, scissor-lift height-adjustable unit, or zero-pressure accumulation zone — standardizes cycle time, reduces ergonomic injury risk, and integrates directly with the automated material flow upstream and downstream of every manual operation. This article covers every conveyor table type in detail and shows how Malaysian electronics manufacturers in Penang, F&B operators in Selangor, and automotive sub-assembly plants use them to close the productivity gap between manual work and automated conveyor flow.

What Is a Conveyor Table?

A conveyor table is an integrated workstation that combines a conveying surface — rollers, belt, or chain — with a structural frame at working height, enabling operators to perform value-adding manual operations (assembly, inspection, testing, packing) on products that arrive and depart under controlled material flow, eliminating the manual lifting, carrying, and positioning associated with static workbenches.

Conveyor tables differ from standalone conveyor sections in three ways: they are designed to ergonomic working-height standards (typically 750–1,100 mm above floor level), they incorporate operator access space (cut-outs, recessed frames, side-access zones) that allows the operator to work at the conveying surface without awkward postures, and they often integrate accumulation capability — the ability to hold products at the station while the operator completes a task, then release them onward without stopping the entire line.

Assembly line conveyor tables are the fundamental building block of manual assembly operations in Malaysian manufacturing. Penang’s EMS factories assembling PCBs, Selangor’s F&B factories packing products into cartons, and Johor’s warehouse sortation centres all use conveyor table configurations matched to their specific operator ergonomic, throughput, and product type requirements.

How Does a Conveyor Table Work?

Conveyor table operation integrates product arrival, operator value-addition, and product departure into a single controlled workstation cycle, driven by the conveying mechanism selected for each application.

Step 1 — Product Arrival and Positioning

Products arrive at the conveyor table from an upstream conveyor section — either by continuous flow (where the belt or rollers run continuously and products move until they reach the operator’s work zone) or by indexed delivery (where a PLC-controlled stop pin or pneumatic stop cylinder releases products one at a time in synchrony with the operator’s cycle). Indexed delivery is the standard in cycle-timed assembly lines where each operation has a defined takt time — the operator completes their task, presses a foot pedal or pushbutton, and the next product arrives within 2–3 seconds.

Step 2 — Operator Ergonomic Engagement

Operator posture at the conveyor table is determined by the table surface height relative to the operator’s elbow height in standing position. OSHA ergonomic guidelines — adopted in Malaysia’s DOSH guidelines under the Occupational Safety and Health Act 1994 — specify that assembly workstation height should be 25–75 mm below elbow height for light precision work and 100–200 mm below elbow height for heavy work requiring downward force. Scissor-lift conveyor tables adjust height electrically or pneumatically from 650 mm to 1,100 mm, accommodating operators of different statures on the same workstation without compromising productivity.

Step 3 — Product Accumulation Within the Station

Zero-pressure accumulation at a conveyor table station prevents product queuing from applying force to the unit being worked on — a critical requirement when products are fragile (PCBs, glass bottles, decorated ceramics) or when the assembly process requires the product to be stationary and unloaded. Zero-pressure accumulation rollers use individually motorized or zone-controlled rollers that stop the roller zone when a product is present, allowing upstream products to queue without contacting the stationary product at the work position. DNC Automation integrates Siemens-controlled zero-pressure roller zones on assembly conveyor table systems for electronics clients in Penang.

Step 4 — Product Departure and Line Balance

Product departure from the conveyor table triggers when the operator signals completion — either manually (pushbutton, foot pedal) or automatically (machine vision confirmation, barcode scan, weight check). The PLC releases the stop mechanism, the conveying surface carries the completed product to the downstream station, and the next product arrives. Line balance — ensuring all stations have equal cycle times — is the production engineer’s primary tool for maximizing line throughput. Conveyor tables with variable-speed drives (Siemens SINAMICS) allow fine adjustment of belt or roller speed at each station to compensate for natural cycle time variation between operators and operations.

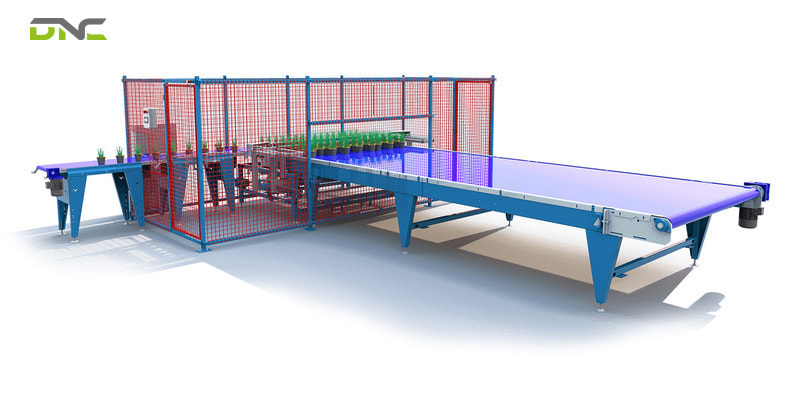

Step 5 — Inspection, Testing, and Quality Gate Integration

Quality gate integration on conveyor tables connects the workstation to in-line inspection equipment. A vision camera mounted above the table surface photographs each product as it passes; the Siemens PLC receives a pass/fail signal from the vision system and either allows the product to continue or diverts it to a reject chute. Checkweigher conveyor tables weigh every product to verify component count (missing parts reduce product weight) or correct assembly (wrong sub-component changes product weight). This integration converts the conveyor table from a passive workstation into an active quality control node within the production system.

Integrating conveyor tables offers a multi-layered advantage for modern factories

Types of Conveyor Table

Conveyor table types are selected based on product weight, operator ergonomic requirements, accumulation needs, and the specific value-adding operation performed at the station.

Gravity Roller Conveyor Table

Gravity roller conveyor tables use free-spinning steel, aluminium, or plastic rollers set on a frame with a slight downward incline (0.5–3°) so products slide forward under gravity without any motor drive. These are the lowest-capital, lowest-maintenance conveyor table type — no motor, no drive, no electronics. Gravity roller tables are appropriate for manually pushed, moderate-to-heavy products (5–100 kg per unit) where operators can control product flow by hand or with simple stop pins. Warehouse receiving stations, automotive parts inspection tables in Selangor, and F&B carton accumulation before hand-packing commonly use gravity roller tables. Roller pitch (centre-to-centre spacing) must be sized so that at least 3 rollers contact the product at all times; typical pitches are 75 mm, 100 mm, and 150 mm for standard carton sizes.

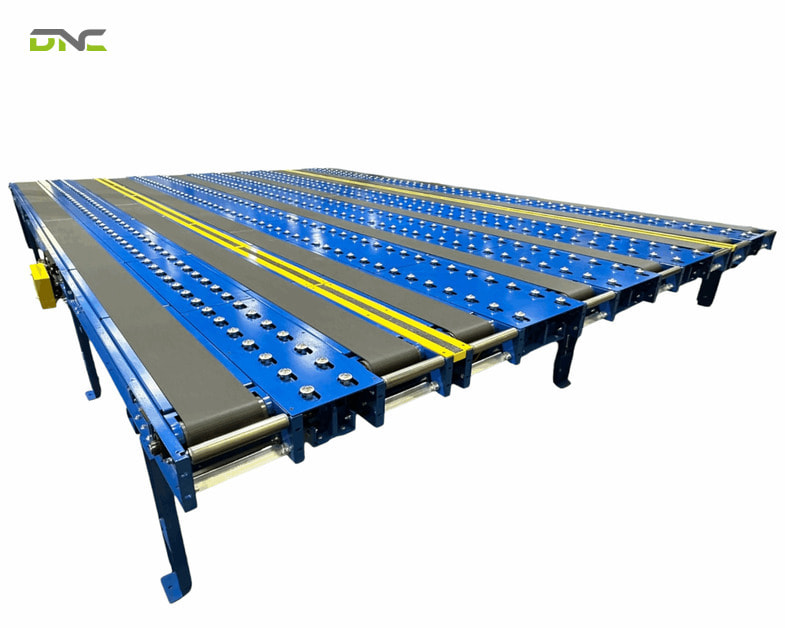

Powered Roller Conveyor Table

Powered roller conveyor tables drive the rollers via a chain-and-sprocket line shaft, poly-V belt, or individually motorized (24V DC) rollers, providing positive, controlled product movement regardless of product weight or surface coefficient. 24V DC motorized roller (MDR) systems are the modern standard: each roller zone contains its own 24V DC motor, enabling independent zone control, zero-pressure accumulation, and fast zone-by-zone commissioning without complex mechanical linkages. MDR conveyor tables at Sony’s Malaysian electronics facility — a DNC Automation client — handle PCB sub-assemblies weighing 0.5–5 kg through multiple assembly and test stations with each zone independently controlled by a Siemens S7-1500 PLC.

Belt-Top Conveyor Table

Belt-top conveyor tables provide a continuous flat surface suitable for small products, parts bags, and assembled sub-components that would fall through or tip over on roller surfaces. The belt surface — PVC, PU, or fabric — is driven by a motorized tail shaft and moves at a constant speed set by the production engineer. Belt-top tables are the standard in F&B secondary packaging lines, pharmaceutical blister-pack verification stations, and electronic component kitting operations where small parts (screws, connectors, small PCBs) must remain on a flat surface throughout the operator’s work cycle.

Scissor-Lift Conveyor Table (Height-Adjustable)

Scissor-lift conveyor tables add powered vertical height adjustment (650–1,100 mm) to the conveying function, allowing the same workstation to be set at the ideal ergonomic height for each operator shift or task type. The scissor mechanism is driven by an electric linear actuator or hydraulic cylinder, activated by a foot switch or pushbutton that operators use without interrupting their work. Scissor-lift conveyor tables are specified wherever operators of significantly different heights share the same workstation (height variation > 150 mm between operators), or wherever the same station performs both heavy work (lower table height) and precision inspection work (higher table height). OSHA guidelines referenced in Malaysia’s DOSH framework identify musculoskeletal disorders (MSDs) as the leading cause of work-related sick leave in Malaysian manufacturing — scissor-lift conveyor tables directly address this by ensuring every operator works in a neutral posture regardless of their height.

Tilting and Rotating Conveyor Table

Tilting and rotating conveyor tables add angular orientation to the height-adjustment capability, allowing the product surface to be tilted toward the operator (15–45° tilt angle) or rotated 90°–360° for access to all faces of a complex assembly. These are used in automotive sub-assembly operations where operators must install fasteners on multiple faces of an engine component or body part, and in electronic equipment assembly where cable routing and connector insertion require access to interior panel faces. DNC Automation engineers tilting conveyor tables for automotive sub-assembly clients in Selangor’s industrial parks, including suppliers to Toyota’s assembly operations.

Accumulation Conveyor Table (Zero-Pressure)

Zero-pressure accumulation conveyor tables create a buffer zone between production operations where products queue without contacting each other, preventing the force transmission that damages fragile products or disrupts assembly precision. Zero-pressure is achieved with MDR zones (each motor stops when a product is detected) or with pneumatic-stop-pin systems (a sensor detects product presence and a pin lifts to block forward movement). Accumulation conveyor tables enable line balancing flexibility: a downstream station that runs slower than average can accumulate a buffer of upstream-produced parts, smoothing out cycle time variation without stopping the entire line.

Comparison Table: Conveyor Table Types

| Type | Drive | Height Adjust | Load (kg) | Best Application |

| Gravity Roller | None (gravity) | Fixed | 5–500 | Warehouse receiving, light assembly |

| Powered Roller (MDR) | 24V DC per zone | Fixed or scissor | 1–300 | Electronics, pharma, F&B packing |

| Belt-Top | Belt motor | Fixed | 0.1–50 | Small parts, F&B packaging, pharma |

| Scissor-Lift | Electric/hydraulic | 650–1,100 mm | 1–500 | Ergonomic multi-operator stations |

| Tilting/Rotating | Actuator/cylinder | Fixed + tilt | 5–200 | Automotive sub-assembly, electronics |

| Accumulation | MDR or pneumatic | Fixed | 0.5–100 | Line buffer, balanced assembly lines |

How Does DNC Automation Customize Conveyor Tables for Maximum Productivity?

Key Components of a Conveyor Table System

A complete conveyor table system integrates the conveying mechanism, structural frame, height-adjustment mechanism (if applicable), control system, and ergonomic accessories into a single functional workstation.

Frame construction — Aluminium T-slot profile frames are standard for electronics and light industrial applications: lightweight, ESD-safe (with earthing connections), rapidly reconfigurable, and compatible with the same T-slot accessory ecosystem as flexlink conveyor systems. Stainless steel frames are used in food-grade environments requiring daily wash-down. Powder-coated steel frames are used in heavy industrial and automotive applications where structural rigidity under high loads (100–500 kg) is the primary requirement.

Roller or belt surface — Roller material selection: galvanised steel for general industrial use; stainless steel for food and corrosive environments; PVC tube over steel for static-sensitive electronics. Belt material: PVC for general; PU for food contact; antistatic PU for electronics; stainless steel mesh for hot or wash-down applications.

Drive and control — MDR 24V DC drives for zone-controlled accumulation; conventional AC induction motors with frequency inverter for continuous-speed belt tables; Siemens SINAMICS G120 drives for variable-speed precision control. All DNC Automation conveyor table control panels use Siemens S7 PLCs with safety relay integration for emergency stop compliance under DOSH Malaysia.

Ergonomic accessories — Foot rests (reduces standing fatigue), anti-fatigue matting (reduces lower limb stress), overhead tool balancers (reduces arm fatigue for torque tools), task lighting (reduces visual fatigue and error rate), component bins and shadow boards (5S organisation, eliminates searching time).

Safety features — Guard panels at pinch points, emergency stop buttons at each operator position, DOSH-compliant nip guards at roller entry/exit points, and LOTO (lock-out/tag-out) provisions on all powered conveyor tables.

Applications: Where Conveyor Tables Are Used in Malaysian Manufacturing

Conveyor table applications in Malaysia cover every sector where human-value-adding work interfaces with automated material flow.

Electronics EMS and PCB Assembly — Penang

Penang’s EMS sector — contributing to 58% of Malaysia’s E&E exports — uses conveyor tables throughout surface mount technology (SMT) and through-hole assembly processes. ESD-safe aluminium frame conveyor tables with antistatic belt surfaces move PCBs between solder reflow ovens, automated optical inspection (AOI) machines, and manual touch-up stations. Takt time at each station is controlled by a Siemens PLC that releases PCBs in synchrony with the line’s master cycle time — typically 15–90 seconds per unit. Sony, a DNC Automation client, uses DNC-engineered conveyor table systems in its Penang electronics manufacturing operations.

F&B Secondary Packaging — Nationwide

F&B secondary packaging operations at manufacturers including Ramly Burger, F&N, and Guan Chong Berhad — all DNC Automation clients — use belt-top and powered roller conveyor tables for carton erecting, product loading, carton sealing, labelling, and case palletizing preparation. The conveyor tables in these environments are stainless steel framed with IP65-rated MDR zones, specified for daily sanitation with food-safe cleaning agents. Accumulation zones on the conveyor tables buffer production rate differences between automatic filling/wrapping machines and manual carton-packing operations performed by 2–4 operators per station.

Automotive Sub-Assembly — Selangor

Selangor’s automotive manufacturing cluster — supplying Toyota, Proton, Perodua, and Inokom — uses tilting and rotating conveyor tables for engine sub-assembly, dashboard installation, and final inspection. Operators install multiple components across the top, bottom, and side faces of engine subassemblies using torque-controlled fastening tools. Tilting conveyor tables allow access to all faces without manual lifting or repositioning. DNC Automation has engineered conveyor table systems for automotive sub-assembly operations in Selangor, integrating torque monitoring and barcode scan verification to ensure each fastener is correctly installed before the assembly progresses to the next station.

Warehouse and Distribution Sortation — Johor

Johor’s logistics and distribution sector — positioned as Malaysia’s gateway to Singapore and the broader ASEAN market — uses gravity and powered roller conveyor tables at sortation and pick-pack stations. Conveyor tables at pick-pack stations provide accumulated inventory presentation to pickers, minimizing walking distance and enabling voice-directed or light-directed picking systems (pick-to-light) to mount their indicator units directly on the T-slot frames. DNC Automation designs conveyor table systems for Johor distribution centres handling 5,000–50,000 order lines per day.

DNC Automation for Your Workstation Transformation

Benefits of Conveyor Tables for Factory Operations

Conveyor table systems deliver four measurable improvements over static workbenches in Malaysian manufacturing environments.

Musculoskeletal injury reduction — Correctly specified conveyor tables at the right working height reduce the incidence of work-related MSDs by 40–60% compared to static benches at fixed heights (based on ergonomic intervention studies). In Malaysia, where MSDs are cited as a leading cause of manufacturing sick leave, reducing injury frequency also reduces the absenteeism cost that Selangor and Penang manufacturers increasingly factor into labour productivity calculations.

Cycle time standardisation — Conveyor tables with timed release — PLC-controlled stop pins releasing products at fixed intervals — force adherence to takt time, reducing inter-operator cycle time variation from ±30–40% (typical on uncontrolled manual lines) to ±5–10%. This standardisation enables line balance improvements that increase throughput by 15–30% without adding labor.

Productivity increase of up to 50% — DNC Automation’s conveyor table installations demonstrate an average 50% productivity increase versus pre-installation manual material handling, consistent with DNC’s documented benchmark. The improvement combines cycle time standardisation, elimination of manual handling steps (carrying, searching, positioning), and integration with automated upstream/downstream material flow.

NIMP 2030 smart factory integration — Conveyor tables with Siemens PLC control, barcode scanners, vision cameras, and SCADA connectivity feed real-time production data into factory MES systems, providing the cycle-time-per-station visibility that NIMP 2030 smart factory standards require. SAG Grant funding (up to RM 1 million, MIDA 70:30 matching) is available for conveyor table investments integrated with such digital manufacturing infrastructure.

How to Choose the Right Conveyor Table for Your Factory

Selecting the correct conveyor table configuration requires matching seven parameters to your specific operation.

Product weight and size determine roller pitch, belt width, and frame load rating. Products below 5 kg on flat surfaces: belt-top tables. Products from 5–100 kg in carton format: powered roller tables with 75–100 mm roller pitch. Products above 100 kg: heavy-duty powered roller tables with steel frame and chain-drive.

Operator height variation determines whether scissor-lift adjustment is necessary. A workforce with height range exceeding 150 mm between shortest and tallest operator justifies scissor-lift investment. A homogeneous workforce with narrow height range can use fixed-height tables at a single ergonomic standard.

Product fragility determines accumulation type. Fragile products (PCBs, glass, ceramics): zero-pressure MDR accumulation mandatory. Robust products (cartons, automotive metal parts): conventional powered roller accumulation acceptable.

Hygienic requirements determine frame and surface material. HACCP/ISO 22000 food environments: stainless steel frame, food-grade belt, IP65/IP69K drives and stops. Electronics: aluminium ESD-safe frame, antistatic belt, clean-room compatibility.

ESD requirements for electronics mandate antistatic belt surfaces, earthed aluminium frames, ESD-safe roller covers, and operator wrist-strap connection points integrated into the table frame.

Control integration level ranges from standalone (simple motor with on/off switch) to fully PLC-integrated (Siemens S7, barcode scanner, vision inspection, SCADA reporting). DNC Automation designs conveyor table control systems at every integration level, from simple manual operations to fully automated takt-timed assembly cells.

Frequently Asked Questions About Conveyor Tables

What is the standard working height for a conveyor table in a Malaysian factory?

Standard working height for standing assembly operations in Malaysia is 900–1,050 mm above floor level for operators of average height (160–175 cm). For seated operations, working height is 700–750 mm. DOSH Malaysia ergonomic guidelines recommend that working height be within 25 mm below the operator’s elbow height for precision tasks. Scissor-lift conveyor tables with a range of 650–1,100 mm accommodate any Malaysian workforce height distribution.

Can conveyor tables be ESD-safe for electronics assembly in Penang?

Yes — ESD-safe conveyor tables use carbon-filled antistatic belt materials (surface resistivity 10^5–10^9 Ω), anodised aluminium frames with earthing connections, ESD-safe roller tube covers, and operator wrist-strap sockets integrated into the frame. Penang’s EMS manufacturers including Sony (a DNC client) operate these configurations on all SMT and through-hole PCB assembly lines.

How do zero-pressure accumulation conveyor tables work?

Zero-pressure accumulation conveyor tables use independently controlled MDR (motorized drive roller) zones, typically 150–500 mm long each. Each zone contains a 24V DC motor, a product sensor (photoelectric or inductive), and logic that stops the zone motor when a product is present in the zone and the downstream zone is occupied. Products queue without contacting each other because each zone is independently stopped. This prevents domino-force transmission that could damage fragile products or displace precise assemblies.

What is the difference between a conveyor table and a regular conveyor section?

A conveyor table is specifically designed for human interaction: it is sized to ergonomic working height, incorporates operator access space, typically includes component storage and tool mounting provisions, and is integrated with accumulation and quality gate features. A regular conveyor section is designed purely for product transport and is not optimised for operator access, working height, or manual operation ergonomics.

How do SAG Grant funds apply to conveyor table investment?

Malaysia’s SAG Grant (MIDA, up to RM 1 million, 70:30 matching) covers automation capital expenditure including conveyor table systems integrated with PLC control, barcode scanning, vision inspection, or MES data reporting. A conveyor table project that eliminates manual material handling steps and provides documented productivity evidence qualifies under SAG criteria. DNC Automation assists all Malaysian clients through the SAG application process as part of its project scope.

Can DNC Automation build custom conveyor tables for unusual product sizes?

DNC Automation (dnc-automation.com) fabricates custom conveyor tables at its 25,000 sq ft facility in Malaysia for any product size, weight, and configuration. The engineering team designs from first principles using aluminium T-slot or stainless steel construction, selecting roller pitch, belt width, drive type, and control system based on product specifications provided during the free consultation. Non-standard widths (up to 2,000 mm), custom lengths, and multi-tier conveyor table systems are all within DNC’s fabrication capability.

What maintenance do conveyor table systems require?

Powered roller conveyor tables require quarterly bearing inspection and lubrication, annual belt or roller surface inspection for wear, and periodic drive unit maintenance (gearbox oil change every 2 years). MDR 24V DC roller systems are essentially maintenance-free beyond annual inspection — the embedded motor is sealed and requires no lubrication. Belt-top tables require belt tension adjustment every 6 months and belt replacement every 3–5 years depending on product abrasiveness and operating hours. DNC Automation provides annual maintenance contracts covering all conveyor table installations in Malaysia.

Conclusion

Conveyor tables are the ergonomic bridge between automated material flow and the human value-adding operations that remain central to Malaysian manufacturing across electronics, F&B, automotive, and logistics sectors. Correctly specifying and integrating conveyor tables — gravity roller for warehouse receiving, MDR zero-pressure accumulation for PCB assembly, scissor-lift for mixed-height operators, and tilting tables for automotive sub-assembly — eliminates the hidden productivity losses of manual material handling, standardizes cycle times, and directly reduces the musculoskeletal injury rates that drive absenteeism and turnover in Malaysian factories.

DNC Automation (dnc-automation.com) — Malaysia’s No. 1 factory automation company since 2005, ISO 9001:2015 certified, with 35+ engineers — designs and builds complete conveyor table systems for Malaysian manufacturers, fully integrated with Siemens PLC controls and SCADA reporting. Talk to our engineers today for a Free Consultation and find out how your assembly line can qualify for the SAG Grant to fund your ergonomic workstation upgrade.

Related reading: Explore DNC Automation’s full range of material handling solutions including transfer conveyors, flexlink conveyor systems, and Siemens-integrated production control panels.

- 10 views

- 0 Comment

Recent Comments