Overview of Cross-Docking Warehouse? Everything you need to know

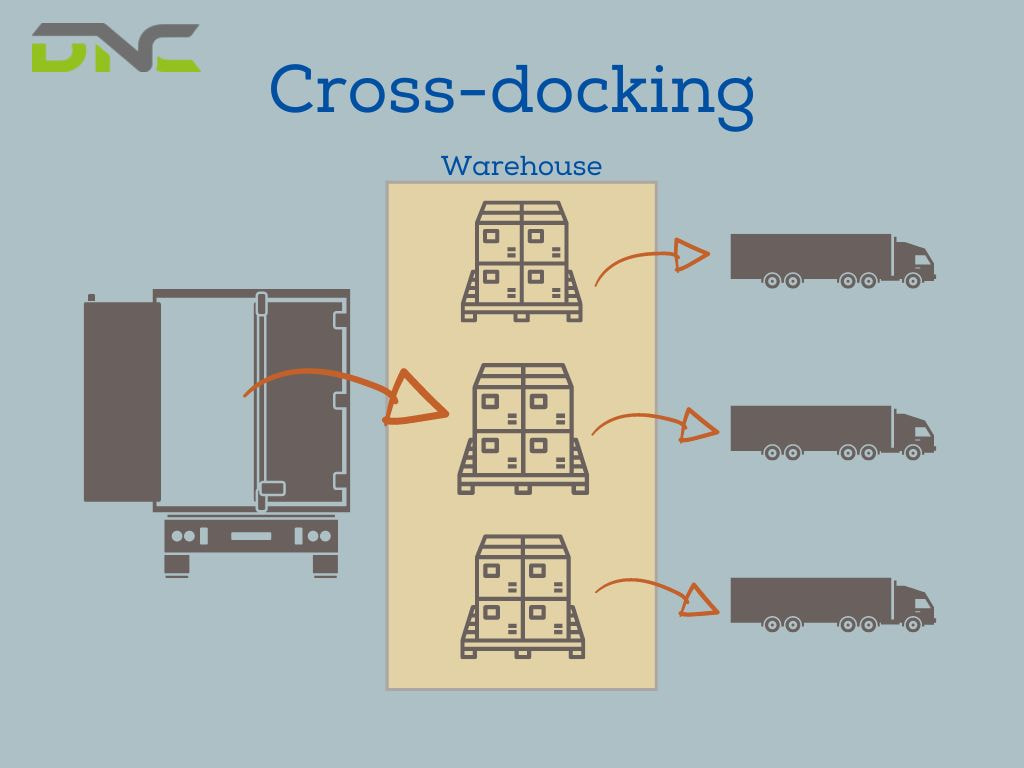

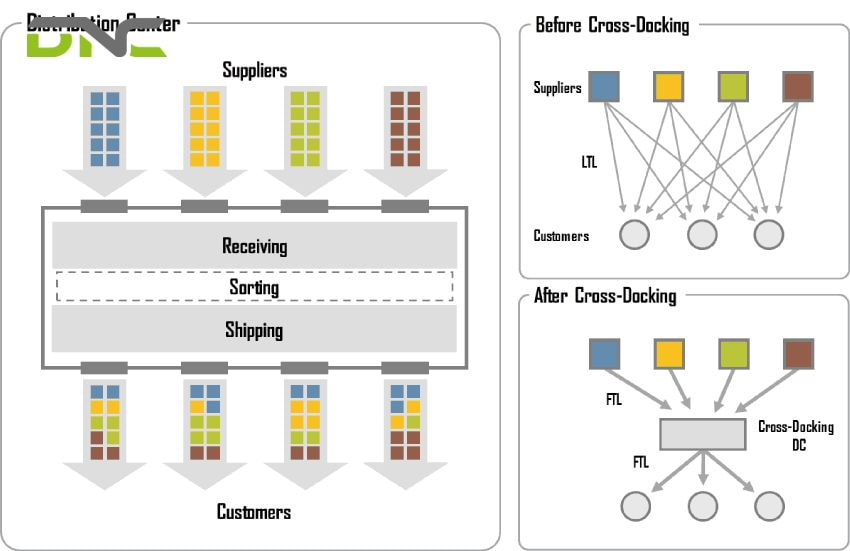

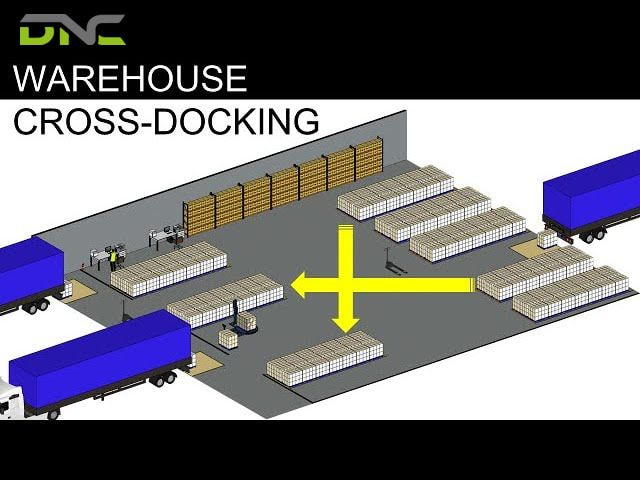

What is a cross-docking warehouse? Cross-docking is a logistics technique that eliminates the storage and order picking steps in warehouse operations. It is a circulation facility where inbound goods are shipped directly to outbound shipments with little or no storage in between. This method minimizes storage time and speeds up product flow, making it a key component of automated warehouse solutions.

Cross-docking is increasingly being implemented in automated warehouse systems to streamline operations, reduce costs, and meet fast delivery expectations. It is especially useful for perishable goods, retail distribution, and industries that require just-in-time (JIT) delivery models.

What are the advantages of cross-docking in the warehouse?

What are the advantages of cross-docking in the warehouse?

By cutting down on the time it takes to transport goods, cross-docking in the warehouse has brought many strategic advantages to businesses, such as:

- Reduced storage costs because many goods are not stored for long periods, so businesses can significantly reduce storage costs and capital investment in inventory.

- Faster order fulfillment as products are moved directly from receiving to shipping, reducing processing times and allowing for faster deliveries, which is great for time-sensitive or high-demand items.

- Improved supply chain efficiency: Cross-docking helps consolidate shipments from different suppliers or distribution centers, allowing for better route optimization and fewer transportation moves.

- Space optimization: This method enables the efficient use of warehouse space, potentially reducing storage requirements and lowering warehouse costs.

How does cross-docking work?

How does cross-docking work?

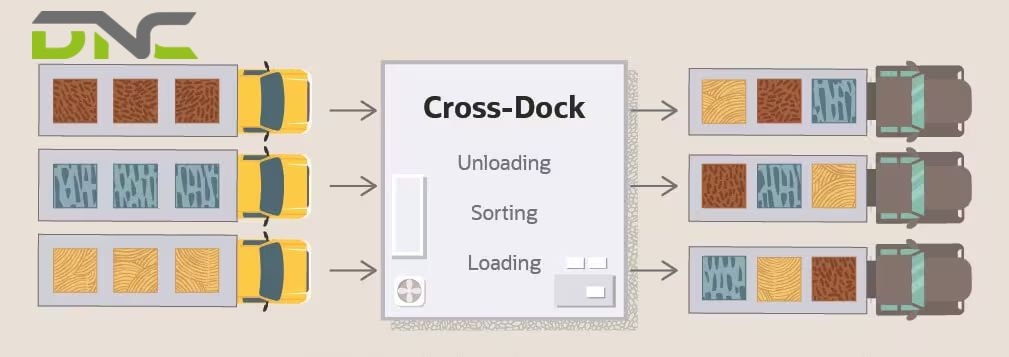

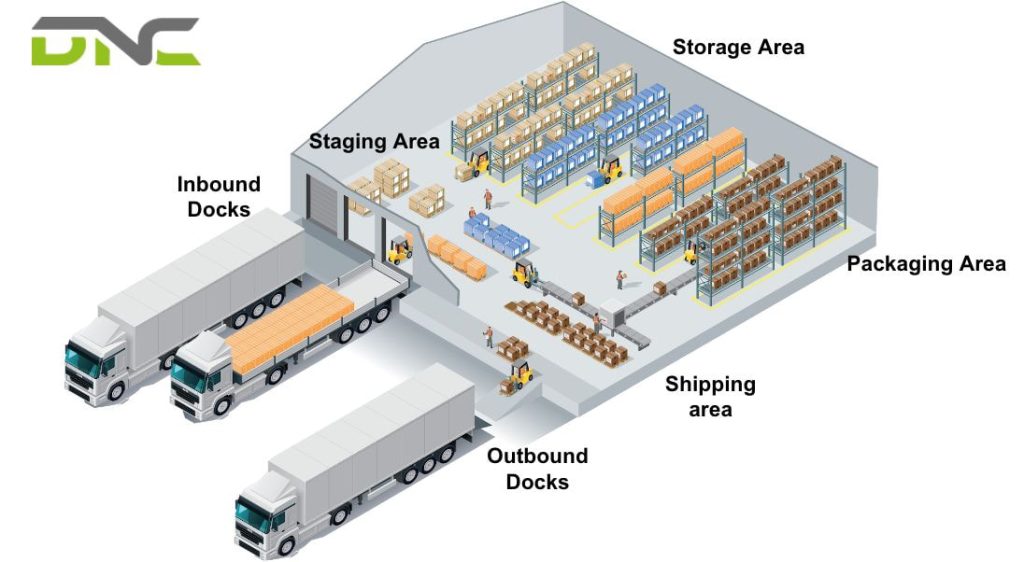

Cross-docking warehouse systems offer many flexible benefits with a specific cross-docking process and follow a streamlined process of receiving, sorting, staging, and shipping out…

- Receiving: This warehouse system will receive products from multiple suppliers or manufacturing locations at the cross-docking facility.

- Sorting and consolidation: Goods are immediately sorted by destination, delivery route, or customer order. This process often involves automated conveyor systems, barcode scanners, and WMS integration.

- Sorting: Items are temporarily sorted at designated dock areas. Unlike traditional warehousing, this sorting process takes place in a short period, usually from a few minutes to a few hours (occurring during the day).

- Shipment: After being sorted, goods are loaded directly onto trucks to retail stores, customers, or other distribution centers.

With such clear operating procedures, combined with automation technologies such as automatic palletizers, automatic sorters, and real-time tracking systems, the efficiency of cross-docking processes has been improved.

What types of cross-dock warehouses are there?

Cross-docking classifications are quite diverse, but the most common are pre-distribution and post-distribution. Each classification will have its own characteristics and processes as follows:

Pre-distribution Cross-Docking

In this model, decisions about the final destination of goods are made before they arrive at the cross-docking facility. Information flows ahead of the physical goods, allowing for rapid routing based on pre-determined orders.

Advantages of Pre-Distribution Cross-Shipment:

- Enables rapid order fulfillment through proactive routing

- Requires accurate demand forecasting and planning

- Ideal for retail chains, grocery providers, and scheduled delivery models

- Relies heavily on WMS and ERP system integration to ensure seamless operations

Post-distribution Cross-Docking

In this version, goods are received first and then routed based on real-time demand or sales data. This model is more flexible but may involve holding or staging for short periods while decisions are made.

Advantages of Post-Distribution Cross-Docking

- Provides greater flexibility in managing customer-specific routing and order changes

- Enables data-driven decision making based on real-time sales data

- Suitable for e-commerce, seasonal merchandise, and fashion retailers

- Supports agile inventory management in high-demand and volatile markets

Where is cross-docking used?

Cross-docking is now quite popular and very flexible in many different industries, from retail, food, to pharmaceuticals, or even Third-Party Logistics.

- Retail and e-commerce: Enable same-day or next-day delivery.

- Grocery and perishables: Minimize spoilage by eliminating storage.

- Pharmaceuticals: Ensure fast and safe delivery of sensitive and urgent medications.

- Third-Party Logistics (3PL): Provide flexible, low-cost storage solutions for customers.

Modern warehouses deploying automated sorting systems, AI-enabled WM,S and IoT tracking are especially suitable for cross-docking operations.

What are the limitations of cross-docking?

What are the limitations of cross-docking?

Despite the benefits of high efficiency, time savings, and storage costs, cross-docking still has some limitations that operators should be aware of:

- High initial setup costs are required because automation equipment, software integration, and warehouse layout redesign require significant capital investment.

- Reliance on accurate data: Any mismatch between supply and demand data can disrupt the flow and lead to delays or errors.

- Limited product suitability: Cross-docking is not ideal for all product types, especially items that require customization or long-term storage.

- Complexity of operations: The speed and precision required mean there is no room for error. Failure in one part of the process can have a ripple effect across the entire supply chain.

What is the difference between cross-docking and docking?

difference between cross-docking and docking

Many businesses still confuse cross-docking with traditional docking. Although both involve moving goods across warehouses, their operating methods, efficiency, and technological requirements differ in several important ways, as follows:

| Feature | Crossing Docking | Docking |

| Storage Time | Minimal to none | Extended periods |

| Product Handling | Direct transfer | Multiple handling steps |

| Warehouse Space Usage | Optimized, smaller footprint | Larger storage areas |

| Best For | Fast-moving, high-volume goods | Bulk inventory management |

| Technology | Requires automation, WMS | Less dependent on tech |

In short, cross-docking is a dynamic, iterative model designed for speed, minimal storage, and automated processes. In contrast, traditional docking relies on long-term storage, multiple processing stages, and slower product movement. Choosing between the two methods depends on your business model, industry requirements, and readiness for automation.

- 7 views

- 0 Comment

Recent Comments