What is the Drag Chain Conveyor? One of The Best Load-Bearing Conveyors

When moving abrasive, hot, or dusty bulk materials, standard conveyors often fail. Drag Chain Conveyors (En-Masse) provide a rugged, dust-tight, and space-saving solution engineered for the harshest industrial environments. DNC Automation leverages a decade of expertise to show you how these heavy-duty systems can maximize your facility’s uptime and operational efficiency.

What is a Drag Chain Conveyor and why is it the “Titan” of bulk handling?

In the hierarchy of material handling, the Drag Chain Conveyor (often referred to as a Scraper or En-Masse Conveyor) is the undisputed choice for the most challenging environments. While belt conveyors are excellent for high-speed, light-duty transport, they fail when faced with high-heat, extreme abrasion, or explosive dust.

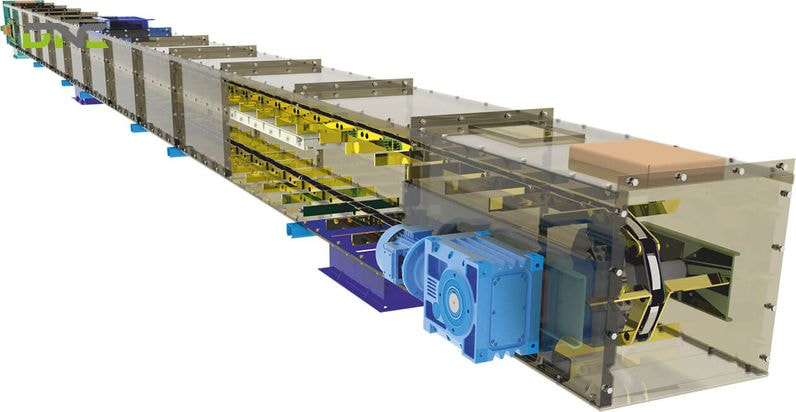

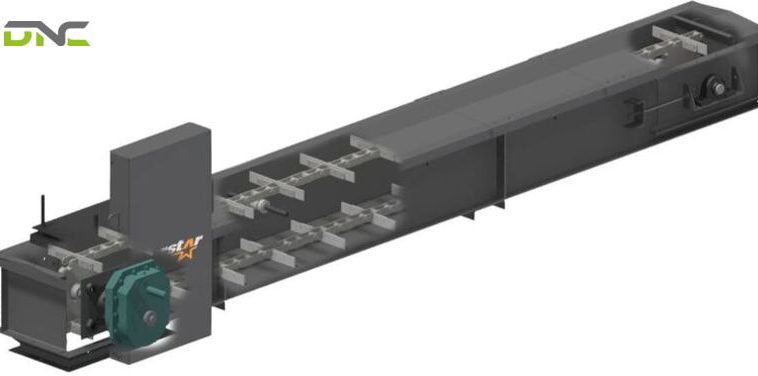

A Drag Chain Conveyor utilizes a high-tensile chain—either single or double strand—fitted with transverse flights (paddles) that pull the material through a stationary, enclosed trough. The reason it is considered essential in heavy industry is its containment capability.

In an era of strict environmental and safety regulations (such as ATEX for dust explosions), the fully enclosed nature of a drag chain system ensures that hazardous dust stays inside the machine, protecting both the workers and the facility.

Drag chain conveyor specifications

- Conveyor belt size: Width 200mm – 1200mm, Length 2000mm – 30000mm, Height can be adjusted based on specific site requirements.

- Frame material: Powder-coated steel, stainless steel (Inox), or aluminum profile

- Chain type: High-strength carbon steel/stainless steel chain

- Maximum load: 50 – 150 kg/m.

- Transport speed: from 0.1 – 0.6 m/s via inverter.

- Power source: 220V – 380V, 50Hz.

- Motor: 0.75kW – 5kW

- Safety features: Integrated emergency stop button, chain tension monitoring system, material blocking sensor, and overload protection alarm.

- Warranty: 12 months

What types of drag chain conveyors are there?

The world of chain conveyors is very diverse. Each type of conveyor has different uses and purposes, and each type is suitable for specific applications.

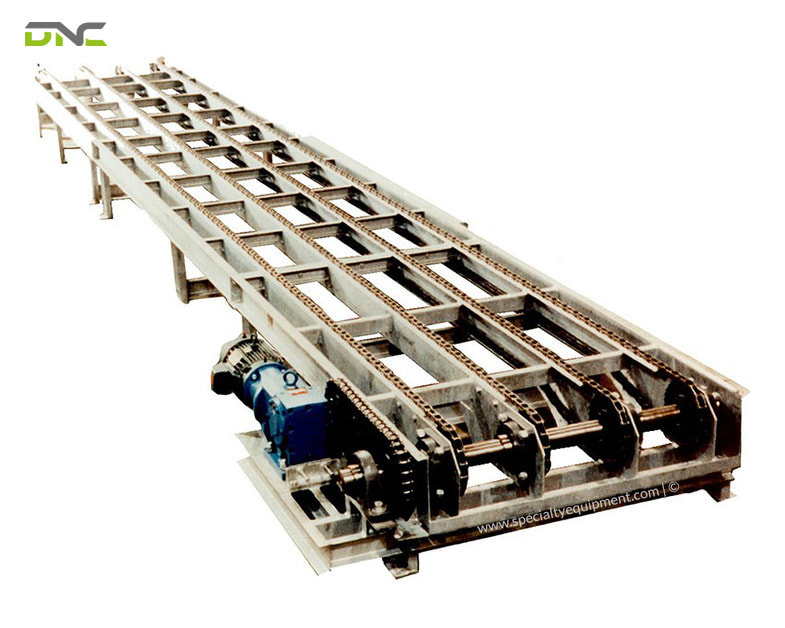

- Single-strand drag conveyor: The equipment will use a single chain and is ideal for lighter applications where space or material volume is limited, suitable for small-scale production models.

- Double-strand drag conveyor: This conveyor will have double the capacity because it is equipped with two chains and is used for heavier loads or bulkier materials.

- Tubular drag chain conveyor: The equipment has a completely sealed tube shell, perfect for moving powders or materials that need to be handled gently.

- Flat-bottom drag conveyor: The equipment is commonly used in agricultural or industrial production plants to move free-flowing materials such as grains, pellets, or minerals.

What are the features of chain conveyors?

What are the features of chain conveyors?

With impressive specifications and a wide range of classifications for different needs, chain conveyors have many outstanding features that make them a favorite choice in many industries:

- High load capacity: Capable of handling very heavy or bulky materials, a chain conveyor chain can weigh more than 1 ton.

- Durability: Made of materials that can withstand harsh industrial environments, including exposure to abrasives, moisture, or high temperatures.

- Versatility: Chain conveyors are easily customized in length and width to fit almost any factory layout, including horizontal, inclined, or vertical transport.

- Dust and contamination control: Specially designed with separate sealed compartments, preventing spillage of raw materials and protecting materials from outside contamination.

The above outstanding features are the typical reasons why drag chain conveyors become a reliable and long-term investment for material handling operations.

How much is a chain conveyor?

How much is a chain conveyor?

How much does a chain conveyor cost? This is one of the most common questions people ask. It is difficult to give an exact price for a drag chain conveyor system because the cost depends largely on the user’s specific requirements, the materials being transported, and the scale of their operation. However, we can still provide a general idea: compared to more complex or specialized conveyor systems, drag chain conveyors are often the more cost-effective option, especially when considering their durability and low maintenance requirements.

Estimated Price Range:

- Small/Lightweight Models: $2,000 – $5,000

- Medium Conveyors: $5,000 – $10,000

- Heavy Duty Industrial Systems: $10,000 and Up

Investing in a drag chain conveyor can be a smart decision, providing benefits through reduced downtime, reduced maintenance costs, and extended equipment life. For smaller projects or temporary operations, rental options are also available to help manage initial investment costs effectively.

How does the “En-Masse” principle redefine mechanical efficiency?

Most people assume the flights simply “push” the material, but the true efficiency of a Drag Chain Conveyor lies in the En-Masse Principle. This is a phenomenon of fluid dynamics applied to solid particles:

- Internal Friction vs. External Friction: When the chain starts moving, it creates a force within the material. The design ensures that the internal friction between the particles of the material is greater than the external friction between the material and the trough’s side walls.

- Volumetric Efficiency: Because of this friction differential, the entire mass of material moves forward as a single, continuous column (a “plug” of material). This allows the conveyor to be filled to 70% or 90% of its cross-sectional area, far exceeding the 20-30% capacity of a standard belt conveyor.

Low Velocity, High Volume: Because the whole mass moves together, the chain can run at a much lower velocity (typically 0.3 to 0.5 m/s) to achieve the same throughput as a high-speed belt. This low speed is the secret to reducing mechanical wear and preventing product degradation.

This is a phenomenon of fluid dynamics applied to solid particles

Why should businesses prioritize Drag Chain systems in their ROI calculations?

The initial CapEx (Capital Expenditure) of a Drag Chain system may be higher than a belt, but the OpEx (Operating Expenditure) tells a different story:

- Total Dust Containment (Safety ROI): In industries handling grain, coal, or sugar, dust is a bomb waiting to go off. Drag chain conveyors are gas-tight and dust-tight, significantly lowering the insurance premiums and the cost of explosion-suppression systems.

- Extreme Material Resilience: These systems can handle materials up to 500°C or higher. A rubber belt would melt instantly. Forged chains are case-hardened to 55-60 HRC (Rockwell Hardness), allowing them to drag jagged rocks, clinker, or scrap metal for years without breaking.

- Multi-Point Loading and Discharge: You can have ten different silos dumping into one drag chain, and ten different gates discharging the material along the route. This “distribution hub” capability replaces the need for complex networks of smaller conveyors.

The initial CapEx (Capital Expenditure) of a Drag Chain system may be higher than a belt

Where is the best place to buy a chain conveyor?

Where is the best place to buy a chain conveyor?

There are many suppliers of drag chain conveyor solutions in Malaysia, but here are four key reasons why DNC Automation should be your top choice:

- Trusted Expertise: Our team of highly skilled technicians has years of hands-on experience in conveyor systems and automation, ensuring you get the best solutions to suit your operations.

- Modern, Sustainable Solutions: We are committed to developing drag chain conveyors that meet modern industrial standards and are also environmentally friendly and energy efficient.

- Quality Guaranteed and Fast Delivery: All our conveyors are 100% genuine, certified, and traceable. We guarantee fast delivery times to keep your production lines running smoothly and efficiently.

- Dedicated Customer Service: We help you determine the right chain conveyor solution for your production scale, specific needs, and budget. Your satisfaction is our top priority.

If you have any questions or need further assistance, please contact us via the hotline below. We are always ready to support you!

- 4 views

- 0 Comment

Recent Comments