Plastic Conveyor Belt: Food-Safe Solutions for Malaysian Factories | DNC Automation Malaysia

Plastic Conveyor Belt — The Food-Safe Standard for Malaysian Factory Operations

Plastic conveyor belts are the backbone of hygienic production lines in Malaysia’s food and beverage manufacturing sector, yet most plant engineers still replace entire belt systems when only a handful of modules are damaged. Factories running rubber or PVC flat belts face a hidden maintenance burden: a single tear forces full-belt shutdown and replacement, costing tens of thousands of ringgit in downtime and material. Plastic modular conveyor belts solve this directly — individual modules snap out and replace in minutes without stopping the entire line. This article covers every material grade, belt type, and selection criterion you need to specify the right plastic conveyor belt for HACCP-compliant Malaysian production, including where DNC Automation has deployed them for clients such as F&N, Ramly Burger, and Guan Chong Berhad.

What Is a Plastic Conveyor Belt?

A plastic conveyor belt is a continuous conveying surface constructed from interlocking thermoplastic modules — typically polypropylene (PP), polyacetal (POM/Delrin), or polyethylene (PE) — that snap together on a hinge-pin system to form a flexible, self-cleaning belt capable of carrying products through food processing, packaging, and industrial manufacturing environments.

Plastic modular conveyor belts differ fundamentally from traditional rubber or PVC flat belts in one structural respect: the belt is not a single continuous sheet but an assembly of discrete, individually replaceable modules. Each module measures approximately 25–100 mm in pitch and interlocks with adjacent modules via a stainless steel or plastic hinge rod. When one module cracks or degrades, a technician removes only that module and snaps in a replacement — without tools, without cutting the belt, and without line shutdown lasting more than 15 minutes.

Food-grade plastic conveyor belts in Malaysia must comply with MS 1480, the SIRIM-certified HACCP standard aligned to Codex Alimentarius principles. All materials — PP, POM, and PE — are FDA-compliant under 21 CFR regulations, making them accepted by Malaysia’s Food Safety and Quality Division (FSQD) and auditors from multinational clients operating under ISO 22000 and BRC Global Standards.

How Does a Plastic Conveyor Belt Work?

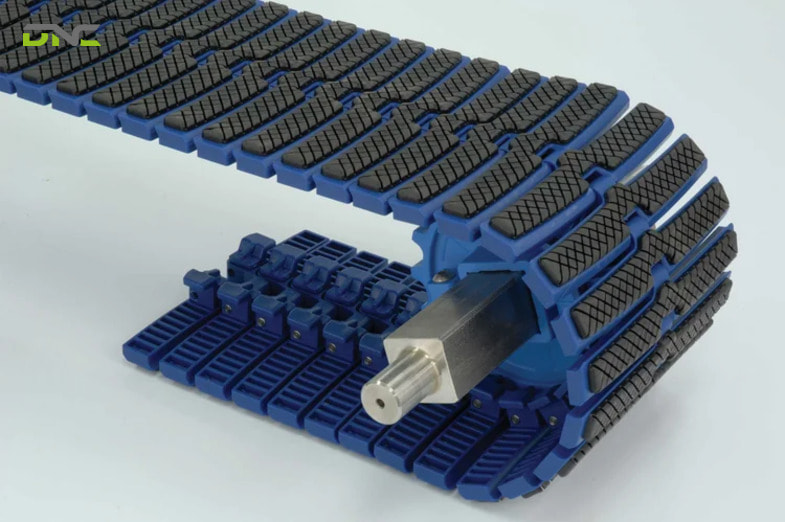

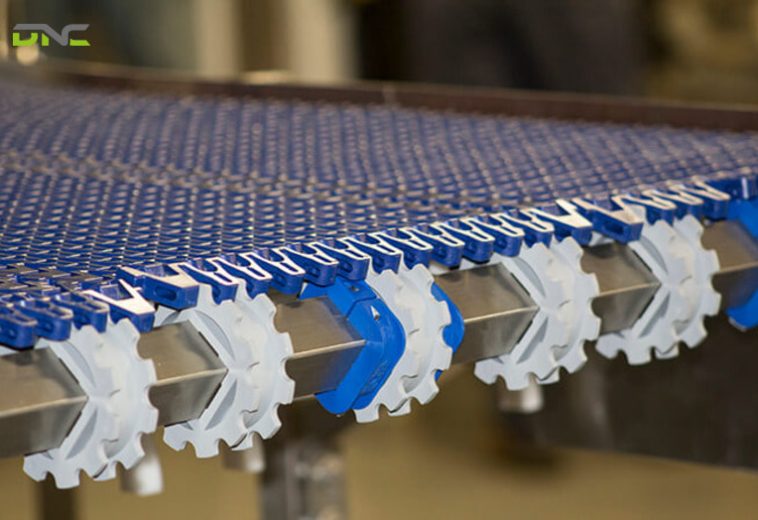

Plastic modular belt systems operate on the same drive principle as any belt conveyor: a drive shaft rotates sprockets that engage with the belt modules, pulling the conveying surface forward over a bed of low-friction support rails or wear strips, then returning the belt on the underside return path.

Step 1 — Module Interlocking and Belt Assembly

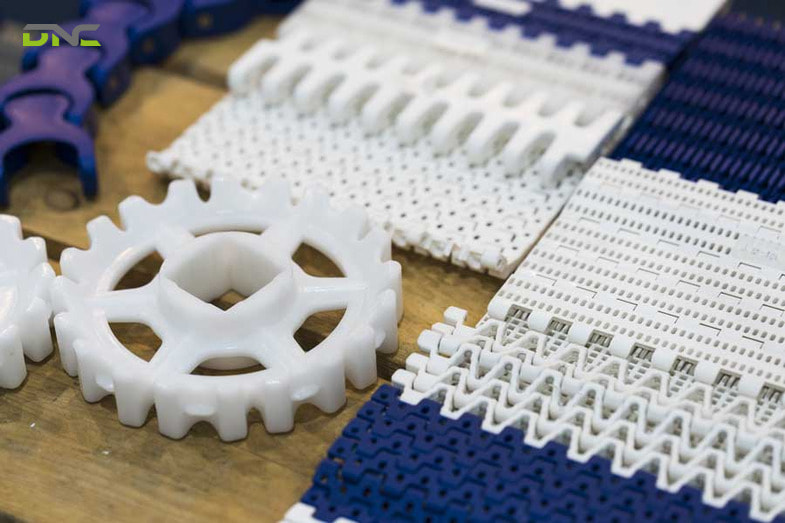

Modular belt construction begins with individual thermoplastic modules aligned row by row. Each row is offset from the adjacent row by half a module width — a “brick-lay” pattern that distributes load evenly and prevents straight-through gaps. Stainless steel hinge rods (or acetal rods in fully non-metallic configurations) are threaded through aligned holes in each module row to connect the belt. The result is a belt that flexes laterally and longitudinally, enabling radius curves without the belt buckling or edge-walking.

Step 2 — Drive Sprocket Engagement

Drive sprockets made from acetal or stainless steel mesh directly with the module’s drive geometry — typically a tooth or lug on the underside of each module. Because the sprocket engages positively, there is no belt slip at the drive shaft, making plastic modular belts more precise in positioning than friction-driven flat belts. This is critical on timed-transfer lines where products must arrive at inspection stations or robotic pick points at exact intervals.

Step 3 — Support Rail and Wear Strip System

Support wear strips made from UHMW-PE (ultra-high-molecular-weight polyethylene) run longitudinally beneath the belt’s carrying surface. The belt slides over these low-friction strips rather than riding on a solid bed. This design creates open space between the belt and the frame, allowing wash-down water, product drip, and debris to fall away from the product contact zone — a critical hygiene requirement for poultry, fruit, and seafood lines.

Step 4 — Return Path and Belt Cleaning

Return-path design on a plastic modular belt conveyor includes spray nozzles, brushes, or a CIP (clean-in-place) module positioned at the tail end. Because the modules are open-structure and non-porous (unlike rubber which absorbs fats and cleaning chemicals), high-pressure wash-down at 60–80°C is possible without belt degradation. DNC Automation engineers typically specify stainless steel frames with NEMA 4X (IP69K equivalent) motor ratings on food-grade installations to allow full daily wash-down protocols.

Step 5 — Module Replacement on Breakdown

Single-module replacement is the defining maintenance advantage. When a module fails — typically from impact damage, chemical attack, or UV exposure on outdoor lines — a technician de-threads the relevant hinge rod section, removes the damaged module, slots in a replacement, and re-threads the rod. Total repair time: 10–20 minutes. For a factory running three shifts, this equates to under 0.5% unplanned downtime per repair event versus 4–8 hours for a rubber belt splice repair.

Plastic modular conveyor belts operate using a positive drive system

Types of Plastic Conveyor Belt

Plastic conveyor belt types vary by base material, surface topology, and the specific application environment they are engineered for. Each type carries distinct temperature limits, chemical compatibility profiles, and hygienic certification levels.

PP Flat Modular Belt (Polypropylene)

Polypropylene modular belts are the workhorse of Malaysian food manufacturing lines. PP offers an operating temperature range of -20°C to +110°C, covering refrigerated storage lines through hot-oven discharge zones in biscuit and bread factories. PP is FDA-compliant, resistant to dilute acids and alkalis found in standard CIP chemistries, and available in FDA-approved colors. DNC Automation supplies PP modular belts in white (standard food contact), blue (for contamination visibility against light-colored foods such as flour and sugar), and natural/cream (general industrial). Guan Chong Berhad, Malaysia’s largest cocoa processor and a DNC client, uses PP modular belts on their cocoa bean sorting and packing lines where resistance to fats and oils is mandatory.

POM Closed-Top Modular Belt (Polyacetal/Delrin)

POM (polyoxymethylene) modular belts offer the widest temperature range of the three primary food-grade materials: -40°C to +120°C. POM’s closed-top surface has a lower coefficient of friction than PP, making it ideal for gentle product handling on lines where sliding friction causes surface damage — confectionery, coated tablets, and glass bottles. POM also provides superior dimensional stability under repeated thermal cycling, so it maintains consistent pitch even after years of daily hot-wash cycles. The material costs approximately 30–40% more than PP, making it the specified choice only where the temperature or friction performance of PP is insufficient.

PE Open-Mesh Belt (Polyethylene)

PE open-mesh modular belts are engineered for drainage-critical applications: poultry evisceration lines, fruit and vegetable washing conveyors, and seafood processing. The open-mesh structure allows water, blood, and debris to drain freely through the belt surface, preventing pooling in the product zone. PE operates at -40°C to +80°C — adequate for most ambient and chilled food processing environments but not for hot-tunnel pasteurizers. Mesh opening sizes range from 4 mm to 25 mm, selected based on product minimum dimension to prevent jamming.

Stainless Steel Modular Belt

Stainless steel modular belts (316L grade) serve applications where thermoplastics reach their temperature or load limits: spiral freezer conveyors (operating at -40°C with heavy product loads), oven belts above +120°C, and high-pressure CIP cycles using aggressive caustic chemicals. Stainless modules interlock identically to plastic modules, preserving all modular replacement benefits. F&N, a DNC client with chilled-beverage production lines in Selangor, uses stainless modular belts on their pasteurizer sections where belt temperature regularly reaches 130°C.

Straight-Run vs. Radius (Turn) Belt

Straight-run belts are uniform-pitch modules used on linear conveyor sections. Radius belts — also called turn belts — use tapered modules that allow the belt to negotiate horizontal curves of 30°, 45°, 90°, or 180° without mechanical guides pressing on product edges. Radius belts are indispensable in factories where floor layout demands curved conveyor paths, such as spiral accumulation towers used in Ramly Burger’s burger patty freezing lines.

Comparison Table: Plastic Belt vs. Rubber vs. PVC Flat Belt

| Attribute | Plastic Modular (PP/POM/PE) | Rubber Flat Belt | PVC Flat Belt |

| Material | PP / POM / PE | Natural/SBR rubber | PVC compound |

| Food Grade (FDA) | Yes — all grades | Depends on grade | Food-grade PVC available |

| HACCP Compliance | Full (open frame, drainable) | Limited (absorbs fats) | Limited (porous surface) |

| Temp Range | -40°C to +120°C (POM) | -20°C to +80°C | -10°C to +60°C |

| Module Replacement | Yes — individual | No — full belt splice | No — full belt replace |

| Maintenance Cost | 40–60% lower than rubber | Baseline | 20% lower than rubber |

| Wash-Down Rating | IP69K with SS frame | Not suitable >60°C | Not suitable >50°C |

| Lateral Curves | Yes (radius belt) | Requires separate curve belt | Limited |

| Typical Application | Food, pharma, F&B | General industrial | Packaging, light industry |

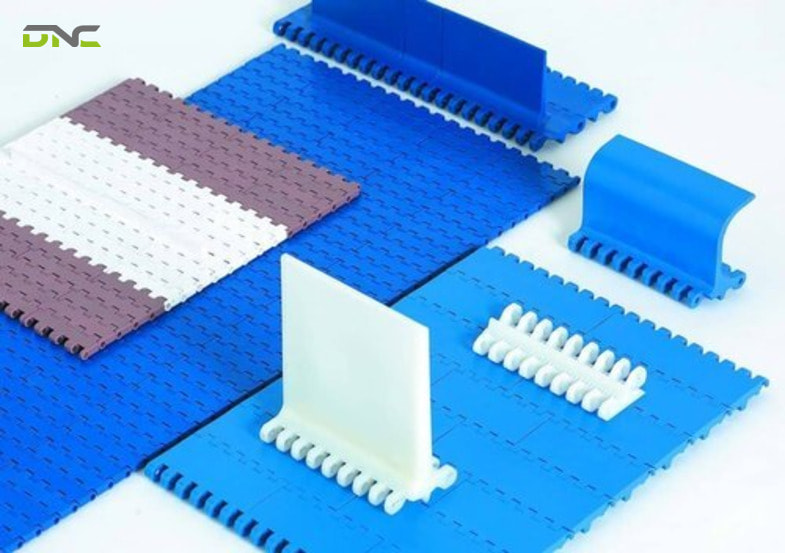

Plastic modular conveyor belts are engineered in multiple configurations to meet specific product handling, hygiene, load, and layout requirements

Key Components of a Plastic Conveyor Belt System

A complete plastic modular belt conveyor system comprises more than the belt modules themselves. Each component must be specified for compatibility with the belt type, load, and hygienic requirements.

Drive unit and gearbox — The motor-reducer combination determines belt speed and pulling force. Food-grade installations require motors rated at IE3 efficiency minimum, with stainless steel or painted-to-food-standard housings. DNC Automation sources Siemens IE3 motors with IP69K ratings for wash-down environments.

Drive sprockets — Sprockets transmit torque from the drive shaft to the belt. Acetal (POM) sprockets are preferred for food grade because they generate no metallic particles; stainless steel sprockets are used for high-torque heavy-load applications.

Carry rail and wear strips — UHMW-PE wear strips support the belt on the carrying side and the return side. Strip replacement intervals are typically 3–5 years under normal food-plant conditions.

Frame construction — Stainless steel 304 is standard for food-contact frames; 316L for corrosive (saltwater, acid) environments. Aluminium profile frames are used in non-food electronics and packaging lines where weight and reconfiguration speed matter more than wash-down resistance.

Belt tensioning and tracking system — Tail-end tensioners (gravity or screw-type) maintain correct belt sag and drive engagement. Lateral tracking guides prevent belt drift on wide conveyors or under asymmetric loads.

Guarding and covers — DOSH Malaysia requires mechanical guarding over drive nip points and exposed sprockets. DNC Automation designs guarding into every conveyor project to comply with the Occupational Safety and Health Act 1994.

Applications: Where Plastic Conveyor Belts Are Used in Malaysian Manufacturing

Plastic conveyor belt applications in Malaysia span every segment of the food and beverage industry, with growing adoption in pharmaceutical packaging and electronics sub-assembly.

Food and Beverage Manufacturing — Nationwide

Malaysia’s food manufacturing sector contributes over RM 60 billion annually to GDP, with concentrated production in Selangor (F&B processing), Penang (confectionery), and Johor (palm oil derivatives). DNC Automation has delivered plastic modular belt systems to F&N’s beverage lines, Ramly Burger’s burger patty production, and Guan Chong Berhad’s cocoa processing facility — all of which operate under HACCP and ISO 22000 certification requiring fully drainable, non-porous conveying surfaces. PP open-mesh belts handle wet-zone product transport; POM closed-top belts handle dry-zone packaging discharge.

Poultry and Seafood Processing — Selangor and Johor

Poultry processing lines operate in the most demanding hygiene environment in food manufacturing: blood, fat, feathers, and aggressive daily chlorine-based CIP cycles. PE open-mesh plastic belts with 8–12 mm mesh openings handle evisceration, portioning, and chilling conveyor sections where complete drainage and bacterial-growth prevention are non-negotiable. Under Malaysia’s Veterinary Health Mark (VHM) scheme, facilities exporting halal poultry to the Middle East and Japan require belt materials that withstand 70°C hot-water disinfection — PE at -40°C to +80°C meets this requirement.

Pharmaceutical Packaging — Penang

Penang’s pharmaceutical and medical device manufacturing cluster — which contributes significantly to Malaysia’s position as the 7th largest medical device exporter globally — uses plastic modular belts in blister-pack filling, tablet sorting, and secondary packaging. POM closed-top belts are specified here because their low-friction surface prevents tablet coating damage during transfer. ESD-safe (carbon-filled) versions of PP and POM are available for sensitive electronic medical device assembly at Penang EMS factories.

Palm Oil Processing — Sabah and Sarawak

Palm oil fresh fruit bunch (FFB) reception and sterilizer feeding in Sabah and Sarawak’s estates uses heavy-duty plastic modular belts on inclined conveyors moving FFB bunches from loading ramps to sterilizer cages. The stainless steel modular variant handles the combination of high heat (sterilizer discharge zones reach 140°C ambient), palm oil contamination, and 24-hour continuous operation that characterizes this sector.

Hygienic Design and Easy Cleaning

Benefits of Plastic Conveyor Belts for Factory Operations

Plastic modular belt systems deliver measurable advantages over legacy rubber and PVC conveying surfaces across four operational dimensions.

Maintenance cost reduction of 40–60% — Individual module replacement eliminates full-belt procurement and the skilled labor cost of belt splicing. A 10-meter PP modular belt requires replacement of 5–15 modules per year under typical food-plant conditions, costing approximately RM 500–2,000 in parts versus RM 8,000–25,000 for a full rubber belt replacement including installation labor.

Hygienic compliance certainty — FDA-compliant materials, open-frame drainage, and hot-wash compatibility reduce the risk of HACCP non-conformance findings during audits. A single failed food safety audit can cost a Malaysian exporter their export license — the risk mitigation value of specifying the correct belt far exceeds the capital cost difference.

Productivity increase of up to 50% — DNC Automation’s installations demonstrate that eliminating unplanned conveyor downtime for belt repairs directly increases line OEE. A food line running 20 hours per day that previously lost 1.5 hours per week to belt repairs recovers 78 hours per year — approximately 3.25 full production days.

Alignment with NIMP 2030 smart factory goals — Malaysia’s National Investment Master Plan 2030 targets the conversion of 3,000 factories to smart-factory status with an RM 8.2 billion budget allocation. Plastic modular belt conveyors with embedded RFID module tracking and PLC-integrated tension monitoring form a foundational layer of the smart-conveyor infrastructure these factories require.

How to Choose the Right Plastic Conveyor Belt for Your Factory

Selecting the correct plastic modular belt requires matching six parameters: product type, operating temperature, chemical exposure, required hygiene level, belt width, and pitch.

Product type determines surface topology — Smooth, closed-top modules for dry goods and packaged products; open-mesh for wet, chunky, or draining products; low-friction POM for fragile or coated surfaces.

Operating temperature defines base material — PP for -20°C to +110°C standard food applications; POM for -40°C to +120°C pasteurizer and hot-tunnel duty; PE for -40°C to +80°C chilled and frozen lines; stainless steel for above +120°C.

Chemical compatibility eliminates unsuitable grades — PP resists dilute acids and bases but degrades in aromatic solvents. POM degrades in strong acids. PE resists most chemicals but softens above +80°C. DNC Automation engineers provide a full chemical compatibility matrix during consultation.

Hygiene level drives frame specification — HACCP-compliant lines require IP69K motors, 316L stainless frames, self-draining frame profiles, and accessible cleaning space (minimum 150 mm clearance beneath the belt).

Belt width and pitch match product and throughput — Standard widths from 150 mm to 1,200 mm; pitches from 25.4 mm (25 series) to 101.6 mm (100 series). Wider pitch = higher open area; narrower pitch = better small-product support.

DNC Automation’s engineering team — with 35+ engineers and 20+ years of Malaysia food manufacturing experience since 2005 — conducts site surveys, product audits, and wash-down compatibility reviews before specifying any plastic belt system. Clients eligible for MIDA’s SAG Grant (up to RM 1 million, 70:30 matching) can offset a significant portion of the system capital cost.

Frequently Asked Questions About Plastic Conveyor Belts

What is the difference between a plastic modular belt and a PVC flat belt?

A plastic modular belt is assembled from individual interlocking modules that can be replaced one at a time, while a PVC flat belt is a continuous sheet that requires full replacement when damaged. Plastic modular belts also offer superior hygiene because their open-frame construction allows full drainage and hot-wash cleaning, whereas PVC flat belts trap moisture and fats at the belt edges and underside.

Are plastic conveyor belts suitable for HACCP-certified Malaysian food factories?

Yes — PP, POM, and PE modular belts are FDA-compliant under 21 CFR regulations and meet the hygiene requirements of Malaysia’s MS 1480 HACCP standard (SIRIM-certified). Their non-porous, easily cleaned surfaces and hot-wash compatibility make them the preferred specification for food safety auditors at factories operating under ISO 22000, BRC Global Standards, and the Malaysian Food Act 1983.

What temperature can a plastic conveyor belt handle?

Temperature capability depends on material: PP handles -20°C to +110°C; POM handles -40°C to +120°C; PE handles -40°C to +80°C. For applications above +120°C — such as conveyor-oven interiors or sterilizer discharge zones — stainless steel modular belts are specified, which interlock identically to thermoplastic modules.

How often do plastic modular belt modules need replacing?

Under normal food-plant conditions with daily wash-down, PP modules in a standard application have a service life of 3–7 years before replacement is required. However, individual modules that suffer impact damage from dropped product, tools, or maintenance equipment are replaced on an as-needed basis — typically 5–20 modules per year on a 10-meter line. This is the key economic advantage over rubber belts, which require full replacement upon any through-cut or splice failure.

Can plastic conveyor belts handle curves and inclines?

Radius (turn) belt variants handle horizontal curves from 30° to 180° without mechanical product guides pressing on product edges. Incline belts use cleated or textured module surfaces to prevent product rollback; maximum recommended incline for most products is 20–25° on cleated belts. Spiral conveyor configurations using radius modules can achieve 360° accumulation in a small footprint — used extensively in DNC-designed freezer spiral systems for F&B clients.

What is the SAG Grant and can it fund a plastic belt conveyor upgrade?

Malaysia’s Smart Automation Grant (SAG) administered by MIDA provides up to RM 1 million per company on a 70:30 matching basis for automation investment. A plastic modular belt conveyor system integrated with PLC-controlled speed drives, automatic tension monitoring, and SCADA connectivity qualifies as automation infrastructure under SAG criteria. DNC Automation assists clients through the SAG application process as part of its project scope.

Why should we use DNC Automation for our plastic conveyor belt system?

DNC Automation (dnc-automation.com) has been Malaysia’s top factory automation company since 2005, with ISO 9001:2015 certification, a 25,000 sq ft engineering facility, and 35+ engineers specializing in conveyor system design and integration. DNC has delivered plastic modular belt conveyors for F&N, Ramly Burger, and Guan Chong Berhad — Malaysia’s largest cocoa processor — demonstrating proven delivery in the country’s most demanding food-grade environments. Unlike distributor-only suppliers, DNC designs, fabricates, installs, and services complete conveyor systems with Siemens-powered control integration.

How do I get started with a plastic conveyor belt upgrade at my factory?

Contact DNC Automation for a free site consultation. The engineering team will assess your current conveyor layout, product characteristics, hygiene requirements, and production throughput to recommend the correct belt type, material, and control system. The consultation is free and includes a preliminary ROI calculation based on your current maintenance costs and downtime history.

Conclusion

Plastic modular conveyor belts represent the highest-value upgrade a Malaysian food or pharmaceutical factory can make to its material handling infrastructure — combining FDA-compliant hygiene, 40–60% lower maintenance costs, and rapid line reconfiguration into a single platform. For Malaysian manufacturers navigating HACCP audits, rising labor costs, and NIMP 2030 smart-factory requirements, the transition from rubber or PVC flat belts to PP, POM, or PE modular systems delivers both compliance certainty and measurable OEE improvement.

DNC Automation (dnc-automation.com) — Malaysia’s No. 1 factory automation company since 2005 — has designed and installed plastic modular belt systems for F&N, Ramly Burger, Guan Chong Berhad, and dozens of other Malaysian manufacturers. Talk to our engineers today for a free consultation and find out how your factory can qualify for the SAG Grant to fund your upgrade.

Related reading: Explore DNC Automation’s complete range of food-grade conveyor systems, including stainless steel frame conveyors, incline conveyors, and Siemens-integrated conveyor control panels.

- 23 views

- 0 Comment

Recent Comments