Enhance Factory Efficiency with DNC SCADA Automation System

Supervisory control and data acquisition (SCADA)

Overview

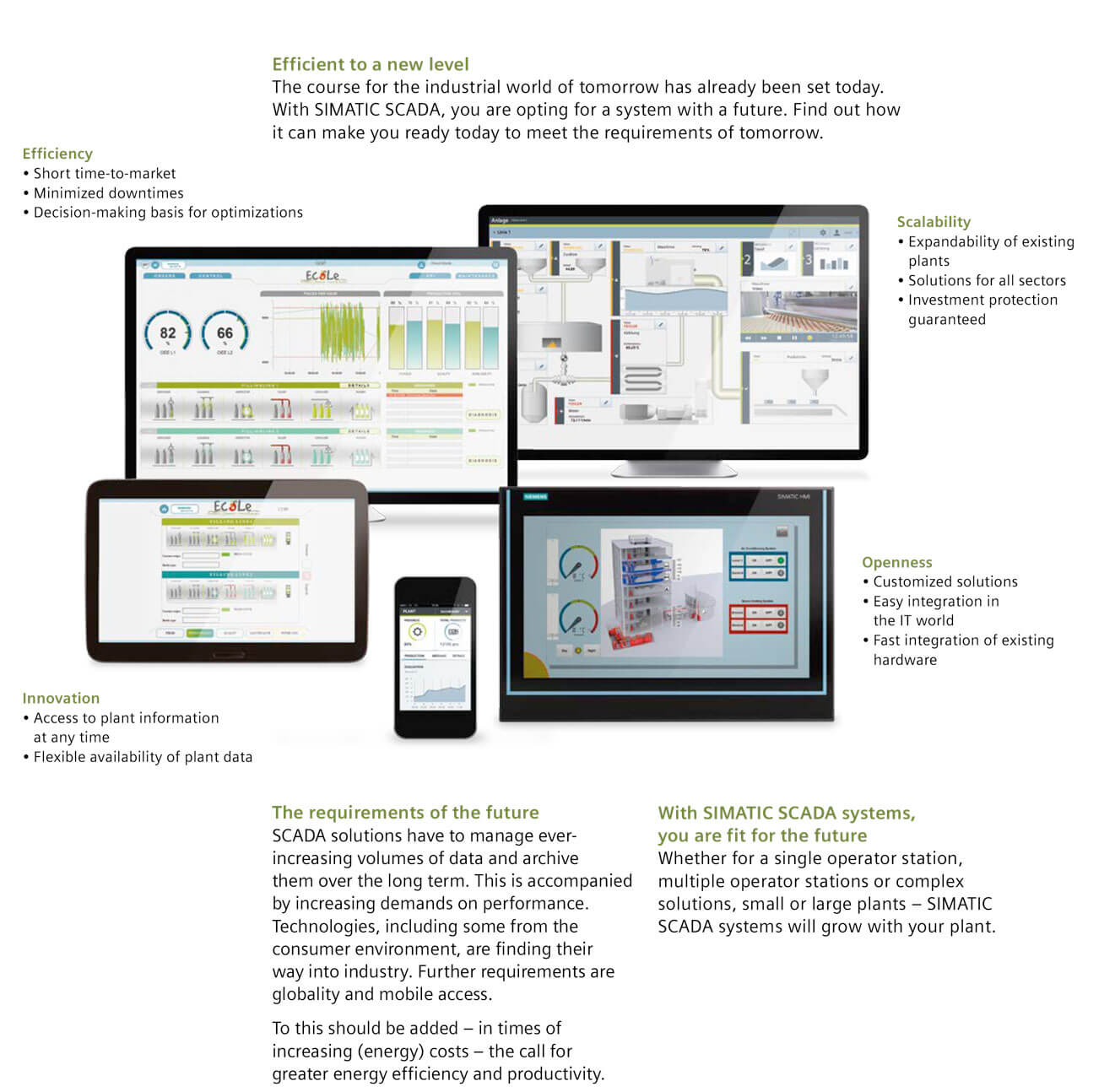

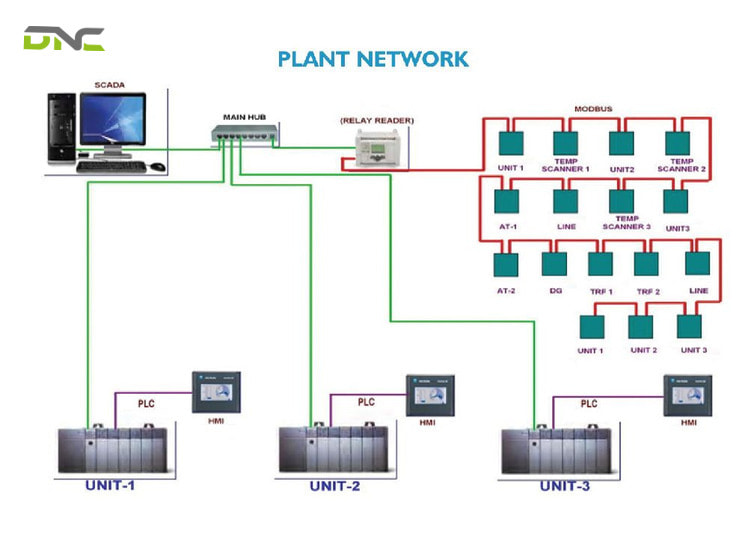

In today’s era of smart manufacturing, real-time data and centralized control have become the backbone of industrial efficiency. SCADA (Supervisory Control and Data Acquisition) systems enable businesses to monitor, control, and optimize their production processes from a single interface — anytime, anywhere.

At DNC Automation, we provide advanced SCADA solutions tailored for modern factories and industrial facilities. Our systems seamlessly integrate with PLCs, IoT devices, and robotics to deliver complete visibility, faster response times, and data-driven decision-making. Whether it’s manufacturing, energy, or logistics, DNC’s SCADA solutions empower industries to operate smarter, safer, and more efficiently.

How Does the SCADA System Works?

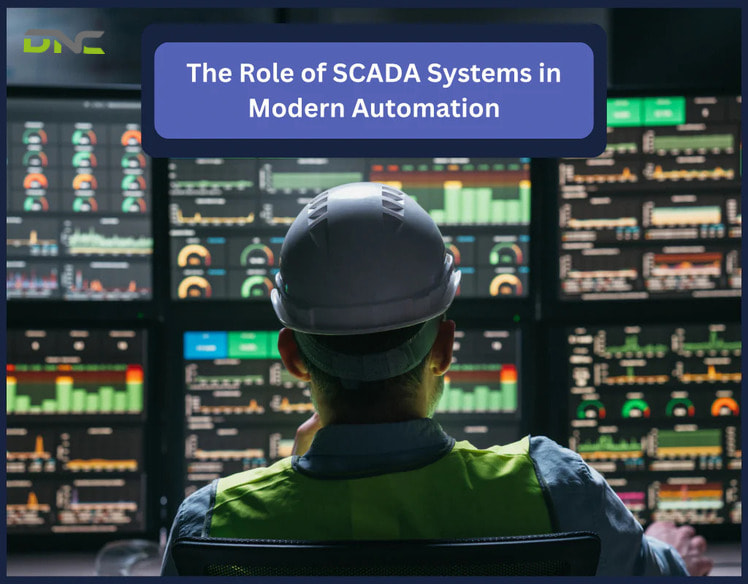

A SCADA system works by continuously collecting real-time data from field devices, processing that information, and allowing operators to monitor and control industrial processes remotely. SCADA system operates in the following 4 steps:

Step 1: Data Acquisition (Collecting Information): Sensors and field instruments measure process variables such as temperature, pressure, flow, or voltage. These signals are sent to local controllers (PLCs or RTUs).

Step 2: Data Communication (Transmitting Data): The collected data is transmitted through industrial communication networks (wired or wireless) to the central SCADA server.

Step 3: Data Processing & Visualization (Supervisory Control): The SCADA software processes the incoming data and displays it on operator interfaces (HMIs) in a clear, visual format — such as dashboards, graphs, or alarms.

Step 4: Control & Decision-Making (Actuation): Operators can send control commands back to equipment through the SCADA interface (e.g., start/stop a pump, open/close a valve), or the system can perform automatic control based on pre-set logic.

Benefits of Implementing SCADA System of DNC

Implementing DNC’s SCADA system helps businesses gain full control and visibility over their manufacturing and utility operations. With real-time data acquisition, automated supervision, and remote control capabilities, DNC SCADA empowers operators to make faster, more informed decisions while minimizing manual intervention.

The system not only boosts productivity but also enhances safety, reliability, and long-term operational efficiency across all production levels. Here are 5 benefits of SCADA system:

- Real-time monitoring and remote control: Access and control critical processes anytime, anywhere.

- Increased productivity and operational visibility: Optimize performance through real-time insights and data analysis

- Early fault detection and reduced downtime: Identify issues before they escalate, ensuring continuous operation.

- Enhanced safety and data-driven decision-making: Improve compliance and safety with accurate, traceable data.

- Scalable and customizable: Easily adapt the system to match the size, complexity, and future growth of any industrial environment.

Benefits of Implementing SCADA System of DNC

How Many Types of SCADA Are There?

For factories and smart warehouses, understanding these SCADA generations is essential to choosing the right system that matches operational needs, investment capacity, and future automation goals. Below are the 4 main types of SCADA systems and their key advantages.

Monolithic SCADA (First Generation)

This was the earliest SCADA model, where all processes were controlled by a single mainframe computer. There was no network connectivity — meaning everything operated locally within one site.

Benefits:

- Simple configuration and reliable performance for small-scale operations

- Ideal for isolated plants with limited monitoring needs

- Low maintenance requirements

Distributed SCADA (Second Generation)

Distributed systems introduced LAN networks, connecting multiple control units that share data within the same facility. This generation improved system efficiency and redundancy.

Benefits:

- Higher reliability with distributed control architecture

- Easy system expansion and maintenance

- Better collaboration between production areas

Networked SCADA (Third Generation)

Networked SCADA uses Ethernet and TCP/IP protocols, enabling communication across multiple sites and facilities. Data can now be centralized, analyzed, and managed remotely.

Benefits:

- Real-time data exchange between remote stations

- Centralized monitoring and control

- Easy integration with ERP, MES, and other enterprise systems

IoT-Based or Cloud SCADA (Fourth Generation)

The latest and most advanced type integrates IoT, cloud computing, and AI analytics, providing complete visibility and control from anywhere.

Benefits:

- Remote access via web or mobile dashboards

- Predictive maintenance through AI-driven insights

- Scalable, flexible, and cost-efficient for modern industries

4 main types of SCADA systems and their key advantages

What are the notes when installing the Scada system?

Implementing a SCADA system is not just about choosing the right software and hardware — it also requires proper planning, design, and integration to ensure long-term efficiency and security. Below are 5 important factors to consider when setting up a SCADA system:

- Define system objectives clearly: Before installation, identify what you want the SCADA system to achieve — such as monitoring energy usage, improving production visibility, or enhancing equipment control.

- Assess existing infrastructure: Evaluate your factory’s current control systems, PLCs, sensors, and communication networks. This ensures compatibility and smoother integration.

- Choose reliable hardware & scalable software: Select industrial-grade components (RTUs, PLCs, HMIs) and software that can scale as your operation grows.

- Focus on cybersecurity: SCADA systems are often connected to enterprise networks or the internet, making them vulnerable to cyberattacks.

- Plan for redundancy & backup: To prevent downtime, critical components like servers and communication links should have redundancy.

5 important factors to consider when setting up a SCADA system

Why Choose DNC for Your SCADA System?

Choosing the right partner is just as important as choosing the right technology. With years of experience in industrial automation, DNC Automation provides not only advanced SCADA solutions but also full project support — from consultation to after-sales service.

- Proven Expertise in Industrial Automation: DNC has extensive experience across multiple industries, including manufacturing, food & beverage, logistics, and electronics.

- End-to-End Project Implementation: From system design and installation to integration and maintenance, DNC delivers complete SCADA solutions under one roof.

- Customizable & Scalable Solutions: DNC’s SCADA systems are flexible and scalable, supporting both small facilities and large industrial plants.

- Strong Technical Support & Training: We provide comprehensive after-sales services, including system maintenance, upgrades, and operator training.

- Focus on Cybersecurity & Reliability: Every SCADA project by DNC follows strict cybersecurity and redundancy standards to ensure continuous, secure operations.

- Proven Track Record & Trusted by Industry Leaders: DNC has successfully implemented automation and SCADA systems for top manufacturers across Southeast Asia.

DNC Automation Malaysia

Conclusion

In today’s fast-paced industrial world, having real-time visibility and control over your operations is no longer optional — it’s essential. DNC’s SCADA System empowers businesses to monitor, analyze, and optimize their production processes seamlessly. With advanced automation technology, scalable architecture, and strong data security, DNC helps enterprises transform traditional manufacturing into smart, data-driven operations.