Screw auger conveyor – High-quality and authentic 2026

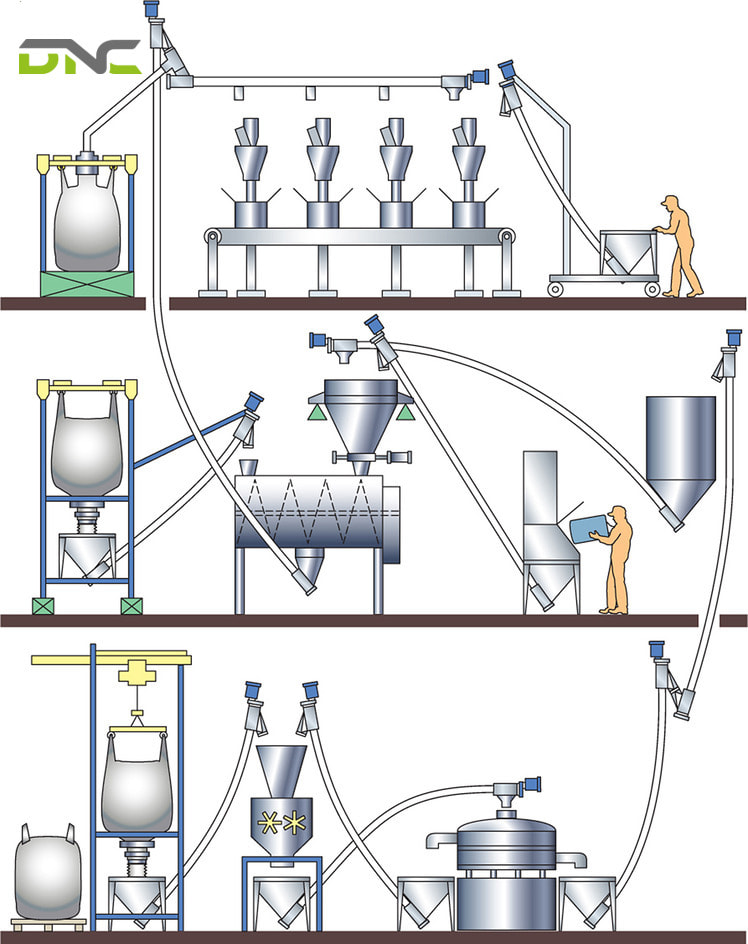

Choosing the right screw conveyor manufacturer is not just about buying equipment—it’s about ensuring long-term operational efficiency, product consistency, and minimal downtime. Many industrial buyers struggle with conveyors that clog, wear out too quickly, or fail to match real production requirements. Whether you handle powders, granules, or bulk materials, a poorly designed screw conveyor can lead to costly interruptions and maintenance issues.

This guide is created to help engineers, procurement teams, and plant managers understand what to expect from a professional screw conveyor manufacturer and how to select a solution that truly fits their process needs.

What Is a Screw Conveyor?

A screw conveyor is a mechanical conveying system designed to move bulk materials using a rotating helical screw blade inside a trough or tube. As the screw rotates, material is pushed forward in a controlled and enclosed manner, making screw conveyors ideal for handling powders, granules, flakes, and semi-solid materials. These systems are widely used due to their simple structure, compact footprint, and ability to operate in horizontal or inclined positions. A professional screw conveyor manufacturer designs these systems based on material characteristics, capacity requirements, and environmental conditions to ensure reliable and efficient material handling.

How many components make up a screw conveyor?

Screw conveyors are composed of 3 main parts as follows:

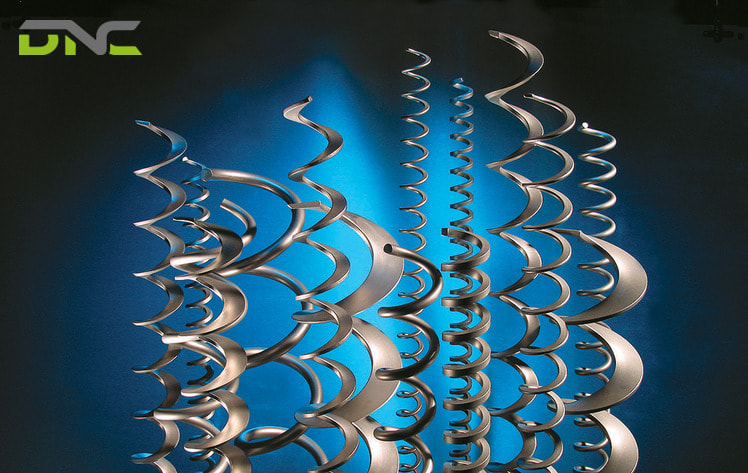

- Conveyor Screw: This is the most important part of a screw conveyor. It consists of a shaft with spiral blades around it, which is responsible for moving raw materials along the length of the trough. There are many types of screw conveyors such as Screw conveyor blades, flying screw conveyors, conical screw conveyors, etc.

- Trough materials: The trough surrounds the screw shaft and supports the storage of bulk materials during transportation, made of stainless steel. We can remove or expand the trough to protect the raw materials from pollution and dirt. There are many types of screw conveyors such as U-shaped troughs, rectangular troughs, tubular troughs, etc.

- Electric motor equipment: Automatic control according to pre-installed design programs.

Structure of screw auger conveyor

How many different types of screw conveyors are there?

Currently, screw auger conveyors are divided into 4 common types as follows: Horizontal screw conveyors, inclined screw conveyors, shaftless screw conveyors, and vertical screw conveyors.

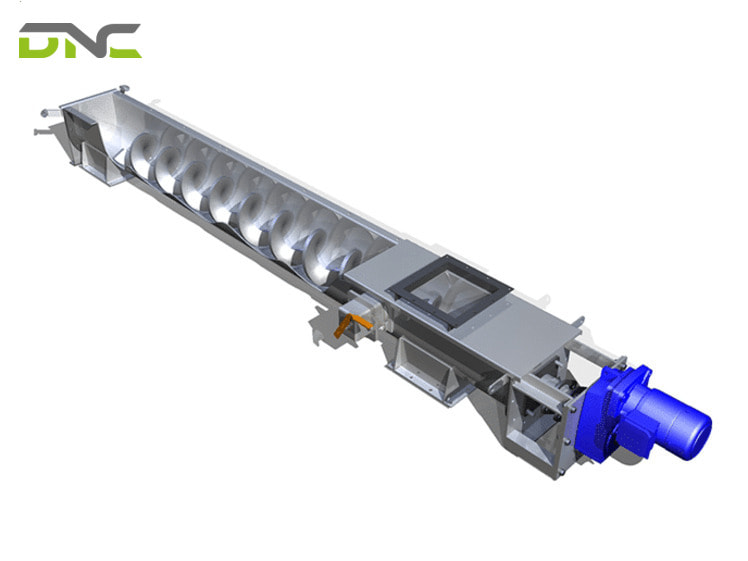

Horizontal screw conveyors

Horizontal screw conveyors are the most widely used type of conveyor. The main function is to transport bulk materials from one process to another.

- Suitable for transporting dry to semi-liquid bulk materials.

- More cost-effective than other types of conveying equipment.

- Completely closed system to avoid dust and corrosion.

- Using multiple input and output points helps to effectively distribute bulk materials to other parts.

Horizontal screw conveyors

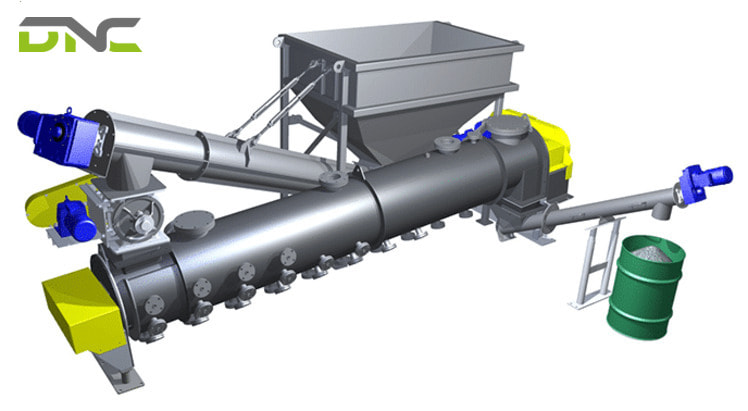

Inclined screw conveyors

Inclined screw conveyors are placed at a 45-degree angle to the ground. As the angle increases, the conveying efficiency decreases and the horsepower must be increased due to the impact of gravity.

- Lower installation costs than other conveyors

- Less likely to clog and jam

Inclined screw conveyors

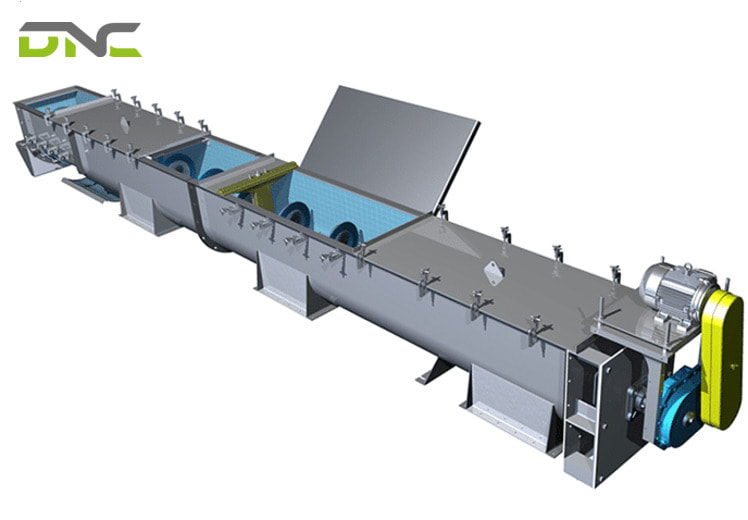

Shaftless screw conveyors

Shaftless screw conveyors make it easier to transport sticky materials because the shaftless design prevents clogging of the conveying surface.

- Suitable for transporting sticky and sluggish bulk materials.

- More efficient than other conveyors.

- Internal bearings are eliminated.

- Parts are easy to install.

Shaftless screw conveyors

Vertical screw conveyors

Vertical screw conveyors lift bulk materials at steep inclines or completely vertically.

- Suitable for transporting dry to semi-fluid materials.

- Capacity: 18.000 cubic feet per hour

- The enclosed design protects against dust and other contaminants

Vertical screw conveyors

What is the difference between a screw conveyor and a tubular drag conveyor?

Screw conveyors and tubular drag conveyors are both widely used for bulk material handling, but they operate on very different principles and suit different applications. Understanding their differences helps engineers and plant managers select the right conveying system based on material characteristics, distance, cleanliness, and maintenance requirements.

| Aspect | Screw Conveyor | Tubular Drag Conveyor |

|---|---|---|

| Conveying principle | Rotating screw pushes material forward | Chain with discs drags material through a tube |

| Material handling | Best for free-flowing powders and granules | Suitable for fragile, abrasive, or mixed materials |

| Conveyor path | Mostly straight, limited routing flexibility | Highly flexible with horizontal and vertical paths |

| Dust control | Enclosed but may generate friction | Fully enclosed, excellent dust containment |

| Maintenance | Simple structure, moderate wear | More components, but low material degradation |

How much does a screw auger conveyor cost?

Is a screw auger conveyor expensive or cheap? This is one of the most common questions for buyers today. It can be said that this conveyor system has a more affordable price compared to other types of conveyor systems.

However, the price of a conveyor line depends on various factors such as operating capacity, technology, and design… Typically, the price of a tubular drag conveyor ranges from $5,000 to $10,000, depending on the production needs of the business.

Price of screw conveyor

How to Choose the Right Screw Conveyor Manufacturer

Selecting the right manufacturer is as important as choosing the conveyor type.

- Engineering expertise: A reliable manufacturer provides technical consultation, not just equipment sales. Design decisions should be based on real process requirements.

- Customization capability: Every production line is different. The manufacturer should offer custom fabrication rather than one-size-fits-all solutions.

- Quality control and fabrication standards: Precision welding, balanced screw fabrication, and material traceability ensure long-term reliability.

Why Is DNC Automation the Right Screw Conveyor Manufacturing Partner?

When selecting a screw conveyor manufacturer, partnering with an experienced and reliable provider ensures your system performs efficiently from day one.

- Proven automation and material handling expertise: DNC Automation delivers engineered screw conveyor solutions designed to meet specific industrial requirements.

- End-to-end solution approach: From design consultation and fabrication to installation support, DNC Automation focuses on long-term operational success.

- Reliable quality and support: Each conveyor is built with durability, safety, and performance in mind, helping reduce downtime and maintenance costs.

If you are looking for a dependable screw conveyor manufacturer that understands industrial processes and automation systems, DNC Automation is ready to support your project.

Contact us now to discuss your material handling requirements and receive a custom-engineered screw conveyor solution tailored to your application.

- 81 views

- 0 Comment

Recent Comments