Screw Conveyor Feeder Explained: Types, Design, Advantages & Applications

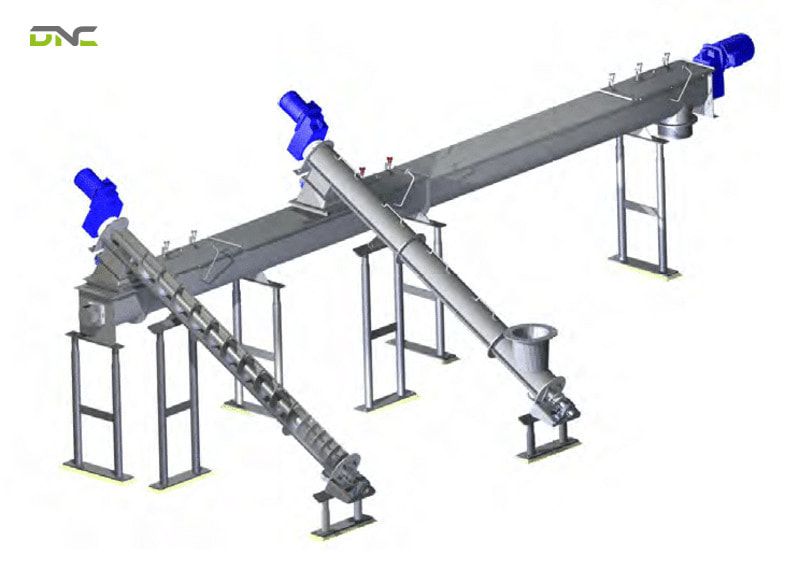

Screw conveyor feeders are used in industrial processes to deliver bulk materials at a controlled and consistent rate into downstream equipment. Designed specifically for feeding rather than simple conveying, screw feeders play an important role in stabilizing material flow and supporting reliable process operation. This article explains how screw conveyor feeders work, the common types used for different material behaviors, and when they are the right feeding solution.

What is a screw conveyor feeder and how does it differ from a screw conveyor?

A screw conveyor feeder is a mechanical device designed to control and regulate the flow rate of bulk material from a hopper, bin, or silo into a downstream process. Although it looks similar to a screw conveyor, its function and design intent are fundamentally different.

Key differences include:

- Primary function: A screw feeder is designed for controlled feeding, while a screw conveyor is primarily designed for material transport. Feeders must deliver a predictable and repeatable flow rate.

- Operating condition: Screw feeders typically operate under a hopper or bin with a constant head of material, whereas screw conveyors usually receive material at a single inlet point.

- Design focus: Screw feeders are designed to maintain consistent material withdrawal along the inlet length, while conveyors focus on moving material from point A to point B.

Because of these differences, using a screw conveyor as a feeder often leads to inconsistent feed rates and unstable processes.

How does a screw conveyor feeder work in material handling systems?

A screw conveyor feeder works by extracting material from a storage vessel and delivering it at a controlled rate into downstream equipment.

The feeding process involves:

- Material withdrawal from a hopper or bin: Material flows into the feeder inlet by gravity. The feeder must withdraw material uniformly to avoid surging or flooding.

- Controlled movement along the screw: As the screw rotates, material is pushed forward along the trough. The geometry of the screw determines how much material is moved per revolution.

- Flow rate control via screw speed: The feed rate is directly related to screw rotation speed, making variable speed control a key element of feeder operation.

- Continuous or intermittent feeding: Screw feeders can operate continuously or be started and stopped based on process demand.

This controlled feeding behavior makes screw conveyor feeders essential in dosing, batching, and process stabilization.

How does a screw conveyor feeder work in material handling systems?

What are the main components of a screw conveyor feeder?

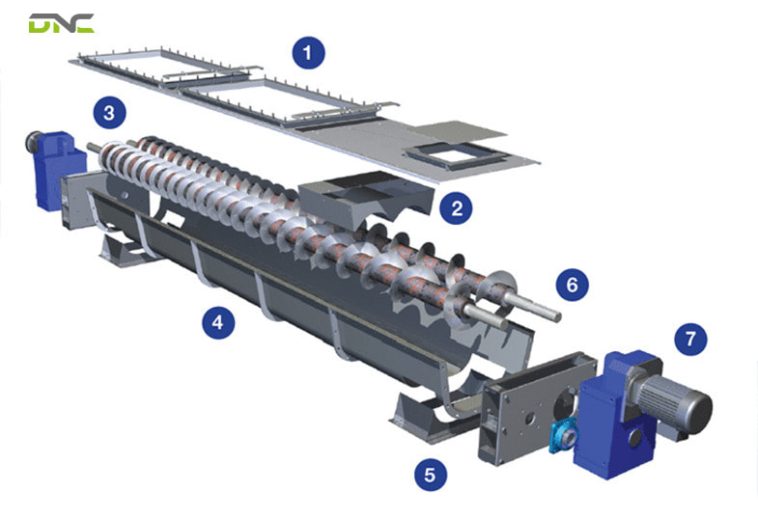

A screw conveyor feeder consists of several key components, each influencing performance and reliability.

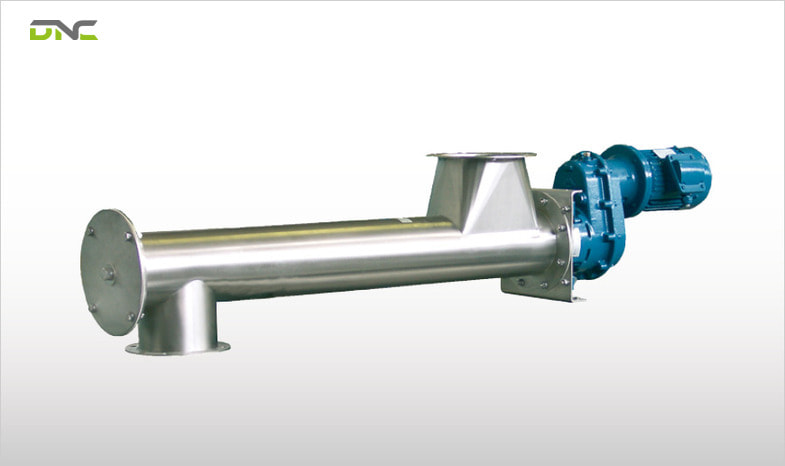

- Screw flight and shaft: The screw geometry (diameter, pitch, and shaft design) determines material capacity and flow behavior.

- Trough or housing: The trough contains the material and supports the screw. Its shape affects material buildup and cleaning ease.

- Inlet hopper: The hopper supplies material to the feeder. Poor hopper design is one of the most common causes of inconsistent feeding.

- Discharge section: The discharge must allow smooth material exit without back pressure.

- Drive unit and speed control: Motors and gearboxes provide torque, while variable speed drives enable precise feed rate control.

- Bearings, seals, and supports: These components maintain alignment and protect against material leakage and contamination.

What materials are screw conveyor feeders designed to handle?

Screw conveyor feeders can handle a wide range of bulk materials, but performance depends heavily on material behavior.

Typical material categories include:

- Free-flowing materials: Such as grains, pellets, and dry powders, which feed easily and predictably.

- Semi-free-flowing materials: Materials with moderate cohesion that may require special screw geometry.

- Poorly flowing or sticky materials: Such as wet powders or fibrous materials, which require careful design to prevent buildup and blockage.

- Fine powders vs granular materials: Fine powders are more sensitive to compaction, while granular materials may cause higher wear.

Screw conveyor feeders can handle a wide range of bulk materials, but performance depends heavily on material behavior.

What factors influence the accuracy and performance of screw conveyor feeders?

Feeder performance depends on multiple interacting factors.

- Screw geometry and pitch: Determines how much material is moved per revolution and affects flow stability.

- Hopper design and fill level: Uneven or fluctuating head pressure causes inconsistent feeding.

- Speed control and drive accuracy: Precise speed control enables repeatable feed rates.

- Material consistency and bulk density: Changes in material properties directly affect output rate.

- Wear and material buildup: Worn screws or buildup alter effective capacity and reduce accuracy.

How do screw conveyor feeders support process control and automation?

Screw conveyor feeders are commonly used as controlled input devices in automated processes.

They support automation by:

- Providing a controllable feed variable: Screw speed can be adjusted automatically based on process demand.

- Integrating with PLC systems: Feeders can be controlled via PLC outputs and monitored through feedback signals.

- Supporting open-loop control: Speed-based control where feed rate is assumed based on calibration.

- Enabling closed-loop control: When combined with weighing systems, screw feeders can adjust speed based on actual material flow.

What advantages do screw conveyor feeders offer compared to other feeders?

Screw conveyor feeders are widely used in industrial processes because they provide a balanced combination of control, simplicity, enclosure, and compactness. When compared with other common feeder types (belt feeders, vibratory feeders, rotary valves), screw feeders offer several distinct advantages depending on process requirements.

- Precise and predictable feed control (within process limits): Screw conveyor feeders deliver material based on rotational displacement: each revolution of the screw moves a defined volume of material forward.

- Compact footprint and efficient use of space: One of the strongest advantages of screw conveyor feeders is their small physical footprint. They combine feeding and conveying in a single enclosed unit

- Fully enclosed material handling: Screw conveyor feeders are typically enclosed by design, which provides major operational benefits:

- Simple mechanical design with high reliability: Screw feeders have a relatively simple mechanical structure, consisting mainly of:

- Cost-effective solution for controlled feeding: From a system-level perspective, screw conveyor feeders are often more cost-effective than alternative feeders when:

- Suitable for a wide range of bulk materials: Screw conveyor feeders can handle many material types, including: With appropriate screw geometry (variable pitch, tapered diameter, shaftless design), screw feeders can be adapted to materials that may be challenging for belt or rotary feeders.

- Easy integration into automation and process control systems:Compared to purely mechanical feeders, screw feeders offer straightforward digital control and process integration.

What advantages do screw conveyor feeders offer compared to other feeders?

- 0 views

- 0 Comment

Recent Comments