Shaft Conveyor – Solution to optimize production process in factory

Shaft Conveyor is an indispensable part of factory automation systems, playing an important role in optimizing production processes. With a sturdy design and stable operation, Shaft Conveyor helps improve performance and reduce operating costs for businesses. In this article, we will introduce the advantages, prices and important notes when choosing Shaft Conveyor for businesses.

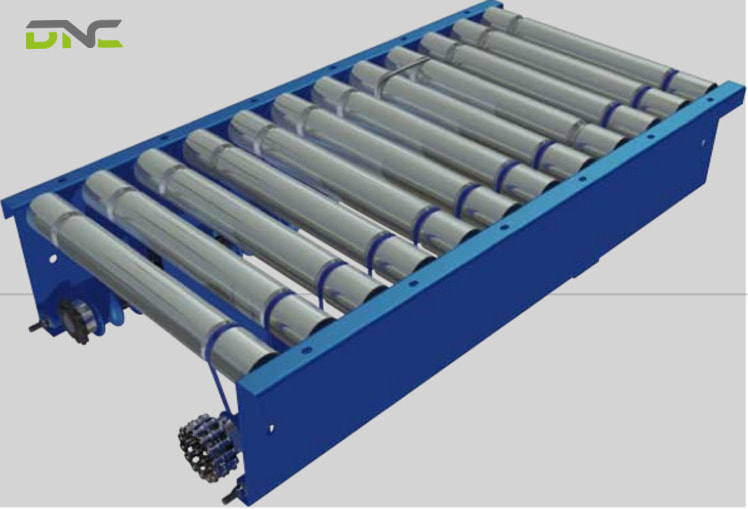

What is a Shaft Conveyor?

In modern industrial automation systems, a Shaft Conveyor is a material conveying device that plays an important role in improving transportation efficiency and optimizing the production line. This is a type of conveyor or screw conveyor that uses a shaft as the main part to transmit motion and transport materials from one point to another.

Choosing and installing a Shaft Conveyor properly not only helps improve labor productivity but also minimizes operating and maintenance costs – thereby improving the overall efficiency of the business.

What are the advantages of a Shaft Conveyor?

Shaft Conveyor is widely used in production systems thanks to many outstanding advantages such as:

- Increase production productivity: Shaft Conveyor helps transport materials continuously, accurately and without interruption like manual methods. Thanks to that, the entire production process is optimized, reducing waiting time and increasing product completion speed.

- Easy maintenance and installation: Shaft Conveyor components are often standardized and easy to disassemble. Technical staff can easily check and replace the shaft or bearings without disassembling the entire system.

- Good conveying efficiency: The shaft design helps control the material flow more effectively, reduces clogging and ensures continuous material movement, suitable for applications requiring large loads.

- Support for automation integration: The Shaft Conveyor can be easily connected to sensors, PLCs, and automatic control systems, helping to synchronize the material transport process with other stages in the production line.

- Flexible customization: Can be designed horizontally, inclined or vertically depending on the factory floor and material properties. In addition, it is easy to integrate with other automatic devices such as sensors, discharge valves, speed controllers, etc.

What are the advantages of a Shaft Conveyor?

What are the things to consider when choosing a Shaft Conveyor for your business?

When choosing a Shaft Conveyor for your production system, businesses need to carefully consider the following factors to ensure optimal operating efficiency and suitability for the requirements of the production line:

- Type of material to be transported: Each type of Shaft Conveyor has the ability to handle different types of materials. Before choosing the type of equipment, businesses need to accurately determine the type of material to be transported: dry, wet, sticky, powder or granular.

- Load volume and speed: If the factory needs to transport a large amount of material in a short time, it is necessary to choose systems with high capacity and speed.

- Maintenance and repairability: Shaft Conveyor systems need to be easy to maintain, replace components and repair when problems arise. Parts such as shafts, bearings, and motors must be designed for easy inspection and replacement.

- Ensure compatibility with automation systems: Shaft Conveyor needs to be designed to be easily integrated with other automation systems in the production line, such as sensors, PLCs, control systems, to optimize operations and improve efficiency.

What are the things to consider when choosing a Shaft Conveyor for your business?

Are Shaft Conveyors Expensive or Cheap?

The price of Shaft Conveyors on the market usually ranges from 10,000 to 20,000 USD. However, the price can vary depending on the following factors:

- System size: Large, long or high load capacity conveyor systems will cost more.

- Material: Materials such as stainless steel, PVC, or rubber will increase the cost. Stainless steel, because of its durability and corrosion resistance, is often more expensive than other materials.

- Motor power: Systems with large motor power (from 5.5kW to 15kW) will cost more than systems with low power.

- Features and technology: Long conveyor systems that integrate modern technology such as PLC, smart sensors and automation capabilities will increase the cost.

To know the exact price of Shaft Conveyor suitable for your needs, you should contact the supplier directly for advice and receive a detailed quote.

The price of Shaft Conveyors from 10,000 to 20,000 USD.

Where to buy reputable automatic shaft conveyor lines?

If you are uncertain where to purchase a shaft conveyor, DNC Automation is an excellent option. Many customers have trusted DNC to provide automation solutions in the production process and have had positive experiences because:

- DNC is a leading technology, automation, and engineering company in Malaysia with over 15 years of experience in the field of automation

- System integration machinery, Internet of Things (IoT), Industry 4.0, and WinCC Scada System

- Diverse designs and sizes are suitable for many domestic and foreign houses. The equipment is 100% genuine and imported from Malaysia.

Please contact us via the hotline below if you have any questions about the product, we are happy to answer you!

- 6 views

- 0 Comment

Recent Comments