What is Delta Robot? Advantages, disadvantages and practical applications

Delta Robots are an industrial robot line that stands out for its outstanding speed and precision. Thanks to its flexible parallel arm design, it is widely used in packaging, assembly and logistics. This article will help you understand the advantages, disadvantages, applications and solutions of Delta Robots from DNC Automation.

What is a Delta Robot?

A Delta robot is a type of industrial robot with a parallel arm structure, usually mounted high and operating in three-dimensional space. With a special design, delta robots are famous for their ability to pick & place with extremely fast speed and high precision.

Different from traditional industrial robots, delta robots are compact, flexible and optimized for high-speed repetitive operations. The parallel arms are controlled by servo motors, helping the robot reach hundreds of cycles per minute while still ensuring stability.

How many parts does a Delta robot consist of?

A delta robot is designed with a characteristic parallel structure, including the following 5 parts:

- Base Frame: Usually mounted above, at the beginning of the entire system. This frame holds the robot firmly and is the fulcrum for the arms to operate.

- Parallel arms: Consists of 3 or 4 robot arms made of lightweight but durable materials (aluminum, composite or carbon fiber). Thanks to the parallel design, the arms can move synchronously and precisely.

- Universal Joints: Connect the arm and the end-effector, making the robot flexible in many directions of movement.

- End-Effector (end tool): This is the part that directly contacts the product, which can be changed depending on the application: vacuum head, mechanical clamp or other specialized tools.

- Control system (Controller): Uses servo motors, sensors and programming software to precisely control movements.

Delta robots operate based on the synchronous movement of parallel arms. When the servo motors control movement, the arms change length and angle, creating fast and precise movements of the end-effector.

Delta robot including 5 parts: Base Frame, Parallel arms, Universal Joints, End-Effector, Control system

What are the advantages of Delta Robots?

Below are 5 outstanding advantages that make Delta Robots the top choice in many industries today.

- Outstanding processing speed: Delta Robots are capable of performing hundreds of pick & place cycles per minute, much faster than traditional robots. Thanks to that, it is especially suitable for high-speed production lines such as food, pharmaceutical or electronic component packaging.

- High precision and repeatability: With a parallel manipulator mechanism and servo motor control system, Delta Robots ensure extremely low errors in repetitive operations. This helps businesses maintain stable product quality and minimize production errors.

- Saving production space: Delta Robots are often hung or installed high up, so they do not take up much floor space. This is a big advantage for factories with limited space or need to optimize production layout.

- Flexible in operation: End-effectors can be easily changed to handle a variety of products – from packaging, small cartons to sophisticated electronic components. This makes the robot well adapted to many different industries.

- Reduce labor costs and increase productivity: By replacing humans in repetitive tasks, Delta Robots not only help reduce labor costs but also increase the overall productivity of the line.

What are the disadvantages of Delta Robots?

Despite bringing many benefits, Delta Robots also have some limitations that businesses need to consider before investing:

- Limited load capacity: Delta Robots are often suitable for light products such as food, electronic components, pharmaceuticals. For large or heavy goods, other types of robots such as six-axis arm robots are more suitable.

- Limited operating range: Due to the parallel arm structure, the working area of Delta Robots is often limited to a certain space, not as flexible as other industrial robot lines.

- High initial investment cost: The Delta Robot system, especially when integrated with vision cameras and advanced control software, has a fairly large initial investment cost, not all businesses can easily deploy.

- Technical and maintenance requirements: Operation and maintenance of Delta Robots require a team of specialized technicians, otherwise it will easily cause disruptions in the production process.

What are the disadvantages of Delta Robots?

What are the practical applications of Delta Robots?

Delta Robots have proven to be highly effective in many industries, thanks to their fast processing speed and high accuracy:

- Food & beverage industry: Delta Robots are used to sort, arrange and package confectionery, beverages, fresh products, etc., helping to ensure food hygiene and safety and increase packaging speed.

- Electronics industry: With the ability to manipulate accurately to the millimeter, robots support the assembly of small components, chips, circuit boards, etc., where the error requirement is almost zero.

- Pharmaceutical industry: Delta Robots are used in packaging drugs, vials and classifying pharmaceutical products, meeting high standards of cleanliness and safety.

- E-commerce & logistics: Support product classification, order packaging and processing of large volumes of e-commerce orders in a short time, increasing warehouse flexibility.

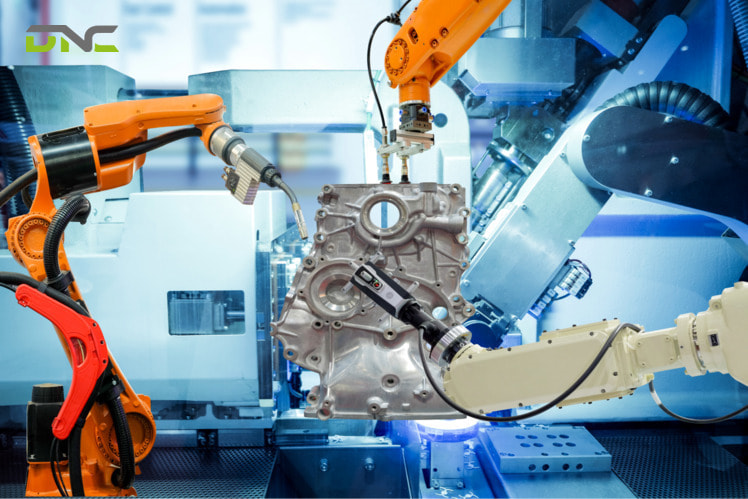

Delta Robots have proven to be highly effective in many industries

Why choose Delta Robot from DNC Automation

DNC Automation provides comprehensive Delta Robot solutions, helping businesses in Malaysia easily access advanced technology and optimize production:

- Consulting & designing suitable solutions: Assessing needs, production scale and proposing optimal robot solutions.

- Integrating delta robots into packaging & production lines: Linking robots with conveyor systems, vision cameras, control software to create a complete automation line.

- Installation, training & maintenance services: Ensuring stable robot operation, trained staff to maximize efficiency.

- Advantages of choosing DNC Automation in Malaysia: Experience in implementing many robot projects, professional after-sales service, complete solutions from A–Z to help businesses save costs and achieve optimal ROI.

- 64 views

- 0 Comment

Recent Comments