What is Vertical Lift Warehouse? The optimal solution for modern warehouse automation

With the ability to store vertically, retrieve goods automatically and save space, Vertical Lift Warehouse not only helps improve operating efficiency but also opens up a new direction for digital transformation in warehouse management. So what is Vertical Lift Warehouse and how is it suitable for businesses?

What is a Vertical Lift Warehouse?

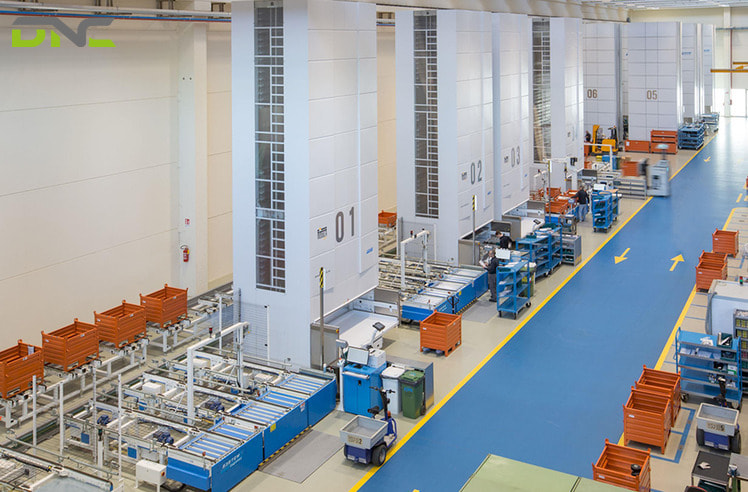

Vertical Lift Warehouse (also known as vertical storage lifting system) is a smart and automated storage solution, using a vertical lifting and lowering mechanism to optimize warehouse space.

This system usually includes two rows of trays placed symmetrically on both sides, in the middle is an automatic lift to help pick up and bring the trays to the appropriate retrieval location.

Vertical Lift Warehouse is part of the Vertical Lift Module (VLM) systems – automatic storage equipment capable of arranging and retrieving goods quickly and accurately through central control software.

What are the outstanding benefits of Vertical Lift Warehouse in warehouse automation?

Not only is it a simple space-saving solution, this system also brings many outstanding values in terms of performance, accuracy and safety. Below are the outstanding benefits that Vertical Lift Warehouse brings to the warehouse automation process.

- Optimize storage space: Vertical Lift Warehouse uses warehouse height instead of floor space, saving 60% to 85% of space compared to traditional shelves. This is an ideal solution for warehouses with limited space.

- Reduce errors in warehouse management: Thanks to the integration of management software and the ability to identify products by barcode or RFID, Vertical Lift Warehouse helps minimize manual errors, ensuring accuracy in inventory and import and export.

- Save labor costs: This automated system reduces dependence on manual labor in tasks such as searching, picking goods or moving trays. Businesses can reduce the number of warehouse staff while still ensuring efficiency.

- Easy integration with warehouse management software (WMS): Vertical Lift Warehouse can integrate with systems such as WMS, ERP, MES, … to improve synchronization and real-time data management, helping businesses optimize the supply chain and control inventory more effectively.

- Increase the speed and efficiency of goods retrieval: The system automatically determines the storage location and quickly transports the tray to the retrieval location.

Benefits of Vertical Lift Warehouse

How is Vertical Lift Warehouse applied in industries?

Vertical Lift Warehouse is not only an ideal solution for conventional warehouses but also flexibly applied in many different industrial fields – where high requirements for speed, accuracy and optimization of storage space are required.

- Electronic components manufacturing industry: ertical Lift Warehouse helps store thousands of component trays classified by code. Technicians only need to enter the component code on the system, the corresponding tray will be automatically brought to the picking location.

- Logistics and distribution center industry: With Vertical Lift Warehouse, products are arranged by SKU in the vertical storage system. When the order is entered into the software, the system will automatically collect goods from the trays for packaging staff

- Medical and pharmaceutical industry: Some large hospitals use Vertical Lift Module to store drugs, expensive medical supplies that require strict control (such as narcotics, surgical supplies).

- Automotive Industry: Major manufacturers use Vertical Lift to store parts by assembly. When workers need to replace or install, the system automatically brings up the tray containing the correct part according to the product code.

How is Vertical Lift Warehouse applied in industries?

When should businesses deploy Vertical Lift Warehouse?

Not all businesses need Vertical Lift Warehouse, but in the following cases, investing in an automatic vertical storage lifting system will help optimize operations, save costs and significantly improve competitiveness.

- When the warehouse is overloaded and lacks storage space: The system takes advantage of the ceiling height to increase capacity without expanding the premises.

- When businesses aim for digital transformation & expansion: If you are on the path to digital transformation of the logistics system or preparing to expand the scale of the warehouse – production, investing in Vertical Lift Warehouse from the beginning will help easily integrate with WMS, ERP systems in the future.

- When businesses need to strictly control high-value goods or need security: Vertical Lift Warehouse integrates software systems, access control, import-export history, suitable for businesses storing expensive components, confidential documents, special drugs, etc.

- When labor costs are increasing: In the context of labor shortages and increasingly high personnel costs, switching to an automated system like Vertical Lift helps reduce dependence on manual labor, while reducing long-term costs for warehouse operations.

When should businesses deploy Vertical Lift Warehouse?

What are the things to consider when choosing Vertical Lift Warehouse for your business?

Investing in the Vertical Lift Warehouse system is an important step in the journey of warehouse automation. However, for the system to maximize efficiency and avoid waste, businesses need to pay attention to the following factors:

- Clearly assess storage needs and available space: Before investing, determine the number of SKUs to be stored? Average size and weight of goods? Floor area and ceiling height?

- Choose a reputable supplier: Storage lift systems are complex mechanical and electronic devices that require regular maintenance and timely support in case of problems. Therefore, businesses should choose a reputable supplier

- Consider investment costs and ROI: Businesses should carefully calculate the expected payback period, which usually ranges from 1-3 years depending on the industry.

- Pay attention to flexibility and scalability: Choose a system with a modular design for easy upgrades or adding more trays/compartments in the future when demand increases.

Businesses need to pay attention to the following factors

What is a reputable vertical lift warehouse provider in Malaysia?

If you are uncertain about where to purchase a vertical lift warehouse, DNC Automation is an excellent option for you. Many customers have trusted DNC to provide automation solutions in the production process and have had positive experiences because:

- DNC is a leading technology, automation, and engineering company in Malaysia with over 15 years of experience in the field of automation

- System integration machinery, Internet of Things (IoT), Industry 4.0, and WinCC Scada System

- Diverse designs and sizes are suitable for many domestic and foreign houses. The equipment is 100% genuine and imported from Malaysia.

Please contact us via the hotline below if you have any questions about the product, we are happy to answer you!

- 4 views

- 0 Comment

Recent Comments