Data-Driven Warehouse: Everything You Need To Know

Data-Driven Warehouse Management is a strategic operational approach that utilizes warehouse data analytics and technology to base decisions on real-time insights rather than intuition or historical guesswork. It involves implementing an intelligent warehouse system where every process, from inventory reception to final dispatch, is tracked, measured, and optimized using data. This forms the foundation of a digital warehouse transformation, shifting operations toward data-based decision-making to improve key performance indicators (warehouse KPIs) like inventory accuracy, order fulfillment speed, and labor utilization.

What Technologies Power Data-Driven Warehouse Operations?

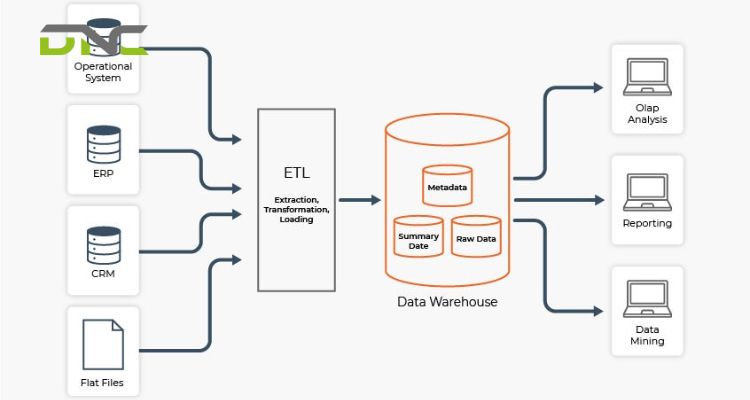

Data-driven warehouse operations rely on the integration of several key technologies:

- IoT Sensors and RFID Tags: These devices collect granular data on location, temperature, condition, and movement of assets and inventory, forming the backbone of IoT warehouse solutions.

- Warehouse Management System (WMS) and Enterprise Resource Planning (ERP): The WMS is the operational hub, managing day-to-day warehouse activities, while the ERP provides the high-level business context. Seamless integration between the WMS and ERP is crucial for unified decision-making.

- Artificial Intelligence (AI) and Machine Learning (ML): These advanced tools analyze vast amounts of warehouse data to predict demand, optimize picking routes, and schedule maintenance, enabling AI-driven logistics.

- Cloud Dashboards: Provide centralized data visualization and accessibility for managers to monitor performance metrics in real-time.

What Technologies Power Data-Driven Warehouse Operations?

How Are Warehouses Evolving from Traditional to Data-Driven Operations?

The shift from traditional to data-driven warehousing represents a fundamental change from reactive, manual processes to proactive, automated ones.

| Feature | Traditional (Manual) Workflows | Data-Driven (Digital) Workflows |

| Data Collection | Paper-based records, manual counts, sporadic spreadsheet updates. | Automated collection via scanners, sensors, and WMS, leading to a real-time data warehouse. |

| Decision Making | Based on intuition, historical averages, or periodic reports. | Based on live analytics, predictive models, and integrated dashboards (analytics-based operations). |

| Visibility | Low; often only known after a physical check or discrepancy alert. | High; complete, end-to-end visibility of inventory, assets, and personnel. |

| Goal | Maintain current operational levels; fire-fighting problems. | Continuous optimization, proactive problem-solving, and warehouse modernization. |

Why Is Data Important for Effective Warehouse Decision-Making?

Real-time data eliminates the lag between an event and its record, which is vital for maintaining inventory accuracy and optimizing fulfillment.

- From Reactive to Predictive Operations: Predictive analytics transforms warehouse management by forecasting issues before they happen — reducing downtime, optimizing maintenance schedules, and improving overall reliability through real-time sensor and machine learning data.

- Order Picking Optimization: By analyzing WMS and location-tracking data, warehouses can refine human and robotic picking routes, boosting throughput, reducing travel distance, and accelerating order fulfillment efficiency.

- Real-Time Warehouse Monitoring: Continuous tracking via RFID and barcode systems ensures up-to-the-second visibility of stock movement, minimizing fulfillment errors and improving inventory accuracy.

- Demand Forecasting: Advanced analytics combine sales data, seasonal trends, and external factors to accurately predict demand, helping warehouses maintain the right stock levels and reduce both overstocking and shortages.

What are the Benefits of a Data-Driven Approach for a Warehouse?

Data-driven warehousing empowers businesses to stay competitive, resilient, and Industry 4.0 ready. By leveraging analytics and real-time insights, warehouses can enhance performance, minimize risks, and align with national smart manufacturing initiatives.

- Improved Efficiency and Reduced Downtime: Real-time monitoring helps predict maintenance needs, preventing costly equipment failures and process disruptions — ensuring continuous operations and boosting overall productivity in automated warehouse environments.

- Enhanced Decision-Making for Business Leaders: Data-driven dashboards and analytics replace guesswork with accurate insights, helping executives plan resources, optimize capital allocation, and make confident, data-backed operational decisions.

- Compliance with Malaysia’s Industry4WRD Strategy: Adopting data-driven systems supports Malaysia’s Industry4WRD initiative by enhancing digital readiness, smart manufacturing adoption, and overall competitiveness in global supply chains.

- Greater Supply Chain Visibility and Customer Value: End-to-end data integration improves transparency, enabling proactive inventory management, faster response to market shifts, and stronger customer satisfaction across Malaysia’s logistics ecosystem.

How Do You Choose the Right Automation Partner in Malaysia?

Looking for companies that have experience with local regulations and integration challenges. The right partner provides not only the technology but also the local support and expertise for the entire project lifecycle.

If you choose DNC Automation, you can get:

- Proven Expertise in Material Handling & Industrial Automation: With a strong local presence and technical expertise, DNC provides reliable, scalable warehouse automation solutions customized to the unique demands of local supply chains, ensuring high-quality

- End-to-End Smart Warehouse Integration: DNC Automation offers complete solutions that cover consultation, design, system integration, and commissioning, providing single-point accountability for the full smart warehouse integration from the sensor level up to the cloud dashboard

- Supporting Malaysia’s Vision for Industry 4.0: We are committed to helping businesses meet and exceed the goals of the Industry4WRD policy, providing the technological foundation necessary to create a highly efficient, competitive, and digitally integrated ecosystem.

- 0 views

- 0 Comment

Recent Comments