Flexible Conveyor Systems for Smart Automation Flow

Modern production and logistics operations face constant pressure to increase efficiency while adapting to changing layouts, fluctuating volumes, and limited floor space. Fixed conveyor systems often lack the flexibility required to support these dynamic conditions, leading to inefficiencies, manual handling, and higher operational costs. A flexible conveyor system addresses these challenges by offering mobility, scalability, and quick reconfiguration without permanent installation.

For operations seeking to optimize material flow while preparing for future automation expansion, flexible conveyors provide a practical and adaptable solution that supports productivity without disrupting existing workflows

What Is a Flexible Conveyor System?

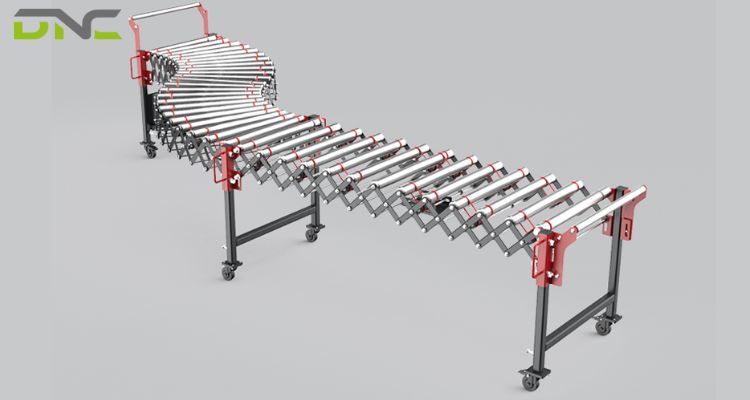

A flexible conveyor system is a modular material handling solution designed to transport products efficiently while allowing quick and easy layout adjustments. Unlike fixed conveyors, flexible conveyors can expand, curve, and reposition to match changing operational requirements. They are commonly used in environments where workflows are dynamic or space is limited.

Flexible conveyors typically feature adjustable frames, roller or belt surfaces, and mobile bases that allow repositioning without tools. This adaptability makes them ideal for operations that require scalable automation, temporary configurations, or frequent layout modifications without costly downtime

How Flexible Conveyor Systems Work in Automation

Flexible conveyor systems are designed to support smooth material flow while adapting to operational changes. Their structure allows products to move efficiently between workstations, loading areas, and automated equipment.

- Expandable and retractable structure: Flexible conveyors use accordion-style frames that extend or compress to fit required distances. This enables efficient loading, unloading, and internal transfer without fixed infrastructure.

- Mobile and repositionable design: Mounted on caster wheels, flexible conveyors can be moved easily across the facility. This mobility supports rapid layout changes while maintaining consistent material flow.

- Powered or gravity-driven operation: Depending on throughput requirements, flexible conveyors can operate using gravity rollers or motorized drives to ensure controlled and continuous movement

Key Benefits of Using a Flexible Conveyor System

Flexible conveyor systems are widely adopted because they address common material handling challenges in evolving automation environments.

- Enhanced operational flexibility: Flexible conveyors adapt quickly to layout changes, supporting operations that require frequent reconfiguration without major system modifications.

- Reduced manual handling: Automating product movement minimizes lifting and carrying, improving workplace safety and reducing labor dependency.

- Efficient space utilization: When not in use, flexible conveyors can be compacted to free up floor space, improving overall facility organization.

- Cost-effective scalability: Flexible conveyors reduce the need for permanent structures, lowering installation costs and enabling gradual system expansion.

Common Types of Flexible Conveyor Systems

Flexible conveyor systems are available in several configurations, each designed to address specific material handling requirements. Selecting the right type depends on product characteristics, throughput needs, and operational flexibility.

Flexible Roller Conveyor

A flexible roller conveyor uses a series of rollers mounted on an expandable frame to transport cartons, totes, and rigid packages. It can operate using gravity or motorized drives, depending on flow control requirements. This type is widely used in distribution, packaging, and sorting operations due to its ability to handle varying product sizes while allowing quick layout adjustments. Its expandable structure makes it suitable for temporary setups or facilities with frequently changing workflows.

Flexible Belt Conveyor

A flexible belt conveyor features a continuous belt surface that provides stable and controlled product movement across adjustable conveyor sections. It is ideal for handling irregularly shaped, lightweight, or fragile items that require consistent support during transport. Motorized belt operation ensures uniform speed and smooth material flow, even when the conveyor is extended or curved. Flexible belt conveyors are commonly applied in packaging lines and production areas where product stability is a priority.

Telescopic Flexible Conveyor

A telescopic flexible conveyor is designed to extend and retract for efficient loading and unloading of vehicles, containers, or trailers. By reaching directly into the loading area, it significantly reduces manual handling and travel distance for operators. This type of flexible conveyor improves loading efficiency, reduces fatigue, and supports higher throughput in distribution and logistics environments. Its adjustable length allows it to accommodate different vehicle sizes without permanent installation.

Industrial Applications of Flexible Conveyor Systems

Flexible conveyors support a wide range of industrial operations by adapting to changing workflows and space constraints.

- Warehousing and distribution: Flexible conveyors streamline order fulfillment by connecting picking, sorting, and dispatch areas efficiently.

- Manufacturing and assembly operations: In production environments, flexible conveyors transport components between workstations while supporting layout changes.

- Packaging and sorting facilities: Their adaptability allows quick adjustment for different package sizes, improving throughput and accuracy.

Flexible Conveyor vs Fixed Conveyor Systems

Choosing between a flexible conveyor and a fixed conveyor system depends on workflow stability, automation goals, and long-term scalability.

Flexible conveyors offer adaptability and mobility, while fixed conveyors are designed for permanent, high-volume production lines. The table below highlights the key differences.

| Criteria | Flexible Conveyor System | Fixed Conveyor System |

| Layout adaptability | Easily adjustable and reconfigurable | Fixed and permanent |

| Installation time | Minimal | Longer installation |

| Mobility | Mobile and repositionable | Stationary |

| Initial investment | Lower upfront cost | Higher infrastructure cost |

| Ideal use case | Dynamic and changing operations | Stable, high-throughput lines |

How to Choose the Right Flexible Conveyor System

Selecting the right flexible conveyor system requires evaluating operational requirements and future automation plans.

- Product characteristics: Consider size, weight, and stability to ensure the conveyor design supports safe and efficient movement.

- Throughput requirements: Determine whether gravity or motorized operation is needed to meet production or logistics targets.

- Layout constraints: Assess available space and expected layout changes to select a system that offers sufficient flexibility

- Long-term scalability: Choose a flexible conveyor that can expand or adapt as operational demands increase.

How Do Flexible Conveyor Systems Support Modern Automation Workflows?

Flexible conveyor systems act as adaptable links between manual handling areas and automated equipment, enabling smoother material flow across changing layouts.

- Controlled material transfer: Motorized flexible conveyors help regulate product flow, reducing congestion and improving process efficiency.

- Seamless connection between processes: Flexible conveyors bridge gaps between machines, workstations, and storage zones without fixed infrastructure.

- Support for phased automation: Their modular design allows gradual automation implementation while maintaining operational continuity.

Why Is DNC Automation a Trusted Partner for Flexible Conveyor Systems?

Choosing the right partner is essential when implementing a flexible conveyor system. Why is DNC Automation trusted for flexible conveyor solutions?

- Automation-driven system design: Each flexible conveyor solution is engineered to align with real operational workflows and automation objectives.

- Application-focused customization: Conveyor configurations are tailored to specific material types, throughput needs, and layout constraints.

- Comprehensive project support: From system planning and installation to optimization, DNC Automation delivers reliable and scalable conveyor solutions.

- 9 views

- 0 Comment

Recent Comments