Common Conveyor Chain Types for Industrial Automation | DNC

In industrial automation, the efficiency of your production line depends heavily on selecting the correct conveyor chain types. The right choice minimizes downtime and maximizes your ROI. In this guide, DNC Automation breaks down the most popular industrial chains to help you find the perfect match for your facility’s specific needs.

What are Conveyor Chain Types and why do they matter for your production line?

In the world of factory automation, a conveyor chain is the “backbone” of material handling systems. Essentially, it is a series of journal bearings held together by constraining link plates, designed to transmit power and transport products through a production line.

Understanding different conveyor chain types is crucial because the wrong choice can lead to frequent breakdowns, high maintenance costs, and decreased throughput. At DNC Automation, we believe that selecting the right chain is the first step toward a high-performing automated system, ensuring your business achieves maximum ROI and operational stability.

What are Conveyor Chain Types and why do they matter for your production line?

Which materials are commonly used in different Conveyor Chain types?

The environment of your factory determines the material of the chain. Here are the three most common options:

- Stainless Steel Chains: These are the gold standard for hygiene-sensitive industries. Their resistance to corrosion and ability to withstand extreme temperatures make them ideal for the Food & Beverage (F&B) and Pharmaceutical sectors.

- Plastic & Modular Chains: Made from high-performance polymers (like Acetal or Polyethylene), these chains are lightweight, quiet, and do not require lubrication. They are perfect for conveying fragile items or products that require frequent washdowns.

- Carbon Steel Chains: If your facility handles heavy-duty loads such as automotive parts or construction materials, carbon steel is the best choice due to its immense tensile strength and durability.

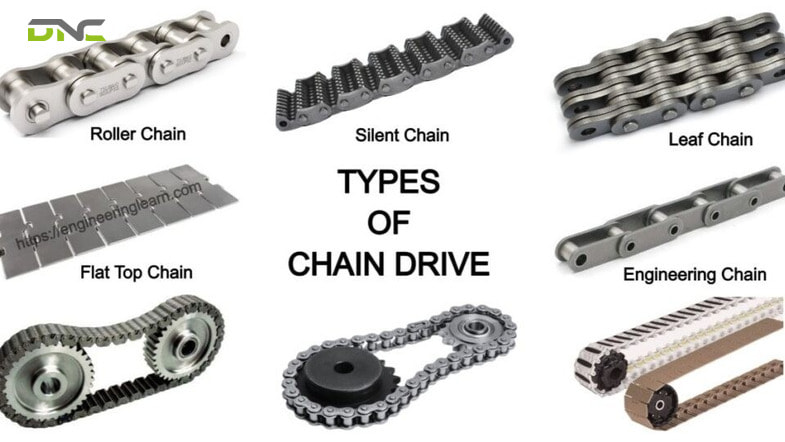

What are the most popular industrial Conveyor Chain types used today?

Depending on the mechanical requirements, conveyor chains come in various designs:

- Roller Chains: The most widely used type. They feature cylindrical rollers that reduce friction, allowing for high-speed transmission and efficient material movement.

- Slat/Table-Top Chains: These consist of individual slats (plastic or steel) linked together to create a flat, continuous surface. They are predominantly used in bottling and canning lines to keep containers upright and stable.

- Modular Belt Chains: These use interlocking plastic segments. The main advantage is repairability; if one part breaks, you only replace a single module rather than the entire belt.

- Double Pitch Chains: Featuring longer link plates, these are designed for long-distance conveyors where the load is relatively light, offering a cost-effective solution compared to standard roller chains.

- Attachment Chains: These are standard chains with “wings” or “attachments” (L-type, K-type, or extended pins). They allow for custom-mounted components to push, pull, or lift specific products.

- Scraper/Drag Chains: Designed to pull bulk materials (like grain, coal, or cement) through a trough. They are essential for heavy industrial material handling.

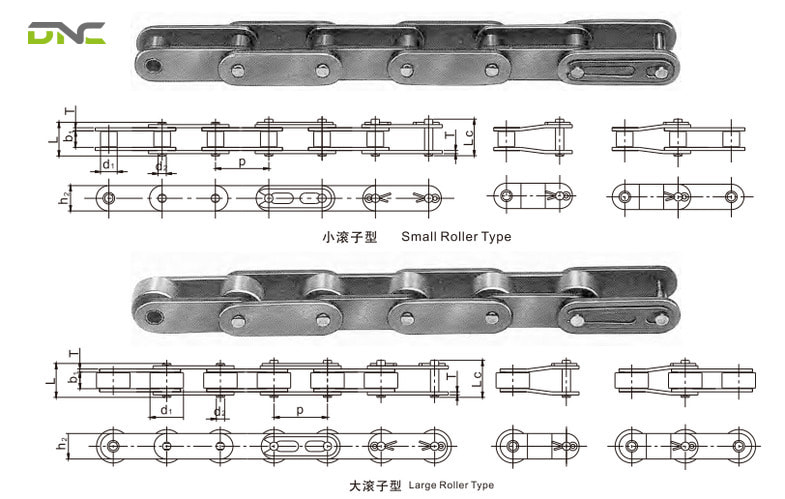

Conveyor Chain types

How do different Conveyor Chain types compare in terms of performance and operational costs?

Choosing the right conveyor chain involves balancing mechanical requirements with budgetary constraints. Below is a detailed technical comparison of the most widely used conveyor chain types in modern automation.

Technical Comparison Matrix

| Chain Type | Material | Load Capacity | Chemical Resistance | Noise Level | Maintenance Needs | Initial Cost |

| Roller Chain | Carbon/Alloy Steel | Very High | Low | High | High (Frequent Lubing) | Moderate |

| Stainless Steel Slat | Grade 304/316 SS | High | Excellent | Medium | Moderate | High |

| Plastic Slat | Acetal / PBT | Low – Medium | Good | Low | Very Low | Moderate |

| Modular Belt | PP / PE / POM | Medium | High | Low | Low (Easy segment swap) | Moderate – High |

| Double Pitch | Steel / SS | Medium | Varies | Medium | Moderate | Lowest |

How to select the right Conveyor Chain type for your specific application?

Selecting a conveyor chain is not a “one-size-fits-all” decision. At DNC Automation, we use a data-driven approach to ensure the chain you choose maximizes uptime. Here is a deep dive into the four critical factors you must analyze:

Analyzing the Total Load & Chain Pull

You must consider more than just the weight of your product. To choose the correct chain strength, you need to calculate:

- Static vs. Dynamic Load: The force required to start a fully loaded conveyor from a standstill is much higher than the force required to keep it moving.

- Chain Pull (Tensile Strength): You must factor in the weight of the chain itself, the friction between the chain and the wear strips, and the weight of the product.

- Safety Factor: For automated industrial lines, we typically recommend a safety factor of at least 7:1 or 10:1 to account for shock loads or unexpected jams in the system.

Evaluating the Operating Environment

The environment is the most common cause of premature chain failure. Ask yourself:

- Temperature Extremes: Will the chain operate in a flash freezer (-30°C) or an industrial oven (+200°C)? Standard steel becomes brittle in cold, while plastic chains may melt or lose structural integrity in high heat.

- Chemical Exposure & Corrosion: If your facility requires “Wash-down” procedures with caustic cleaning agents, Grade 304 or 316 Stainless Steel or specialized Acetal plastics are mandatory to prevent oxidation.

- Abrasive Conditions: In industries like cement or mining, dust and grit can act like sandpaper between the pins and bushings. In these cases, hardened steel chains or specialized dust-sealed chains are required.

Required Precision, Speed, and Indexing

In modern automation, the conveyor is often part of a precise robotic sequence.

- Indexing Accuracy: If your chain needs to stop at an exact millimeter for a robotic arm to pick up a part, you need a chain with low “initial stretch.” High-quality roller chains are often pre-stretched at the factory to ensure they don’t elongate during the first few weeks of use.

- Chain Vibration (Chordal Action): At high speeds, the way a chain engages with the sprocket can cause slight pulsations (vibration). To achieve smooth movement for delicate items (like glass or electronics), DNC Automation engineers often recommend smaller pitch chains or specialized low-friction modular belts.

How to select the right Conveyor Chain type for your specific application?

Why is DNC Automation your trusted partner for Conveyor Chain solutions?

At DNC Automation, we don’t just supply parts; we provide total automation solutions. Our team of experts understands the nuances of various conveyor chain types and how they integrate into a larger smart factory ecosystem.

- Engineering Expertise: We help you calculate the exact specifications needed for your conveyor system to prevent over-engineering or under-performing.

- High-Quality Sourcing: We partner with global manufacturers to bring you chains that meet ISO and ANSI standards.

- Support & Optimization: Beyond installation, we offer maintenance audits and optimization services to ensure your production line never stops moving.

Identifying the right conveyor chain types is essential for any modern manufacturing facility. Whether you need the hygiene of stainless steel or the heavy-duty power of carbon steel, DNC Automation has the expertise to guide you.

- 11 views

- 0 Comment

Recent Comments