Chip Conveyor: CNC Swarf & Coolant Management for Malaysian Machining | DNC Automation

Chip Conveyor — The Productivity Multiplier That CNC Machining Operations in Malaysia Overlook

Chip conveyors determine whether a CNC machining cell runs at 85% OEE or 60% OEE — and most Malaysian precision engineering shops discover this only after the sixth spindle stoppage of the month caused by chip accumulation in the machining zone. Unmanaged metal swarf from turning, milling, and grinding operations shuts down machine spindles, contaminates coolant tanks, creates operator slip hazards, and destroys the cutting fluid chemistry that keeps tool life within acceptable cost parameters. In Selangor’s automotive machining clusters machining Toyota engine blocks and transmission cases, and in Penang’s precision engineering facilities producing aerospace and electronics housings, chip and coolant management is not a secondary concern — it is a direct determinant of machining productivity, tool cost, and machine uptime. This article covers every type of chip conveyor, the chip morphology of every major workpiece material, how to recover and reuse cutting fluid, and how DNC Automation engineers complete chip and coolant management systems for Malaysia’s most demanding machining operations.

What Is a Chip Conveyor?

A chip conveyor is a machine integrated into or adjacent to a CNC machining centre, lathe, milling machine, or grinding machine that continuously removes metal swarf (chips, turnings, and fines) from the machining zone and transfers them to a chip collection container, while simultaneously recovering cutting fluid (coolant) from the swarf and returning it to the machine’s coolant tank.

Chip conveyors (also called swarf conveyors or chip removal conveyors) perform two simultaneous functions: chip removal and coolant recovery. The chip removal function prevents swarf accumulation in the machine enclosure, which causes spindle damage, tool breakage, operator injury from sharp curled swarf, and fire hazard when chips accumulate against hot machine components. The coolant recovery function returns up to 90% of the cutting fluid carried out of the machining zone with the chips — fluid that represents a direct operating cost of RM 5,000–50,000 per machine per year depending on coolant concentration and machine volume.

Swarf conveyor selection depends entirely on chip morphology — the shape, size, and material of the chips generated by the specific machining operation. Cast iron produces brittle, granular chips (fragite); aluminium produces long, curly chips; steel produces long, stringy chips that tangle; titanium produces fine powder and short fragments. Each chip type requires a different conveyor mechanism to transport reliably without jamming, wrapping, or clogging.

How Does a Chip Conveyor Work?

Chip conveyor operation combines a mechanical chip-transport mechanism with a coolant drainage and filtration function in a compact package designed to mount within the CNC machine’s footprint.

Step 1 — Chip Generation and Entry at the Machine

Chips generated during machining fall from the cutting zone by gravity into the machine’s chip pan — a sloped sheet metal tray beneath the machining table that channels swarf toward the chip conveyor entry port. The chip conveyor is positioned at the lowest point of the chip pan, typically at the rear or side of the machine tool enclosure. Some machine tool configurations use internal spiral augers inside the machine enclosure to pre-move chips from multiple machining zones to a central chip conveyor inlet — DNC Automation engineers these internal swarf handling systems for multi-pallet horizontal machining centre installations.

Step 2 — Chip Transport Through the Conveyor Mechanism

The chip transport mechanism carries swarf from the machine enclosure floor level up an inclined section (typically 30–45°) to a discharge height of 600–1,200 mm above floor level, allowing chips to fall by gravity into a collection container (bin, cart, or chip briquetter). The transport mechanism — hinged steel belt, scraper paddles, magnetic drum, auger, or drum filter — is selected based on chip morphology and contamination requirements. The mechanism runs on a dedicated motor (typically 0.25–1.5 kW) that is interlocked with the machine tool’s CNC controller: conveyor starts when the machine spindle starts, stops after a purge delay when the machine stops.

Step 3 — Coolant Drainage Through the Conveyor Body

Coolant drainage occurs as chips travel along the conveyor’s inclined section. The conveyor body is a sealed trough with drain holes or filter screens positioned along the incline. Cutting fluid drains from the chips by gravity, passes through filter screens that capture fine chips and swarf particles, and flows into the machine’s coolant tank. Coolant return rates of 80–95% are achievable with well-designed chip conveyors, recovering coolant that would otherwise be lost with the chips into the collection bin, where it contaminates the chips and reduces their scrap metal value.

Step 4 — Discharge and Collection

Chip discharge at the conveyor’s upper end deposits swarf into collection bins sized for one to two shifts of chip production. A typical CNC turning centre machining steel at medium removal rates produces 50–200 kg of chips per shift; heavy-duty machining centres on cast iron or aluminium produce 200–800 kg per shift. Collection bins are equipped with forklift pockets or integral chip carts for transfer to external chip briquetting stations or direct sale to metal scrap merchants. DNC Automation integrates chip collection monitoring (load cell under bin or proximity sensor for bin-full detection) with the machine control system to alert operators before overflow occurs.

Step 5 — Coolant Tank Filtration and Reconditioning

Coolant tank management downstream of the chip conveyor involves secondary filtration (removing fine swarf particles below 100 µm that pass through the conveyor’s primary screens), coolant concentration monitoring (refractometer-based, maintaining 6–10% emulsion concentration for most water-soluble metalworking fluids), and periodic coolant replacement. DNC Automation specifies drum filter or centrifuge coolant filtration systems for high-volume machining installations, extending coolant life from 3–6 months (unfiltered) to 12–18 months (filtered), saving RM 10,000–50,000 per machine per year in coolant replacement cost.

Chip conveyors play a direct role in machining efficiency and reliability

Types of Chip Conveyor

Chip conveyor types are matched to chip morphology — the wrong conveyor type for a specific chip shape results in jamming, wrapping, or incomplete chip removal, undermining the productivity benefit the conveyor is intended to provide.

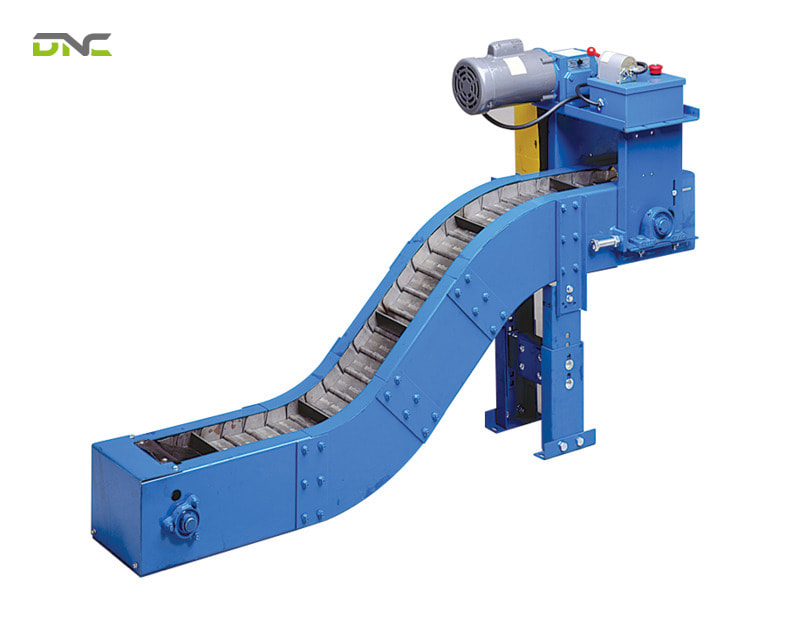

Hinge Belt Chip Conveyor

Hinge belt chip conveyors use a continuous belt of flat, hinged steel plates (pitch 50–100 mm, width 100–500 mm) to carry chips from the machine floor to the discharge point. The flat plate surface prevents chips from falling back on the return path; the hinged construction allows the belt to navigate the inlet curve and incline geometry within the machine’s footprint. Hinge belt conveyors are the most versatile type, handling long stringy steel chips, curly aluminium swarf, and mixed chip loads without jamming. They are the standard specification for steel machining (turning, milling, drilling) where chips are typically 5–50 mm in length with a curled or C-shaped morphology. Toyota automotive machining facilities in Selangor — machining steel engine blocks, crankshafts, and transmission cases — use hinge belt chip conveyors as the standard chip removal method.

Scraper (Drag) Chip Conveyor

Scraper chip conveyors use hardened steel paddles mounted on a drag chain to sweep chips along the bottom of a flat-bottom trough toward the discharge. Scraper conveyors are appropriate for small, granular, or fragite chips (cast iron, brass, bronze, small-pass grinding swarf) that would fall between the plates of a hinge belt. Cast iron machining generates brittle fragments (fragite) that flow readily under paddle dragging — the scraper is the natural and cost-effective solution for cast iron applications. Malaysian die casting facilities machining aluminium die castings use scraper conveyors for the short, granular chips generated by facing and boring operations. Scraper conveyors are limited to horizontal or shallow inclines (< 15°) and are not suitable for long, stringy chips that wrap around the drag chain.

Magnetic Chip Conveyor

Magnetic chip conveyors use permanent magnets (ceramic or rare-earth) embedded under a thin stainless steel belt to attract and transport ferrous chips — steel, cast iron, and stainless steel swarf — while the belt slides beneath, carrying the chips along by magnetic attraction. Because the magnet-chip contact is through the belt rather than mechanical contact, the belt surface has no recesses or hinges for chips to jam in, making magnetic conveyors extremely clean in their chip-carrying mechanism. Magnetic chip conveyors deliver the cleanest coolant return of any chip conveyor type — virtually no fine ferrous particles carry through to the coolant tank, extending coolant life significantly. Magnetic conveyors are restricted to ferrous-only applications; they cannot convey aluminium, titanium, or non-metallic materials. Precision grinding operations in Penang’s aerospace supplier facilities use magnetic conveyors for precision steel part grinding where fine grinding swarf contamination of coolant is the primary concern.

Drum Filter Chip Conveyor

Drum filter chip conveyors combine chip removal with primary coolant filtration in a single machine. A rotating drum with a perforated stainless steel filter screen captures chips from the incoming swarf-laden coolant; the filtered coolant flows through the drum into the clean coolant tank; chips accumulate on the drum exterior and are scraped off by a wiper blade into a collection bin or hinge belt for further transport. Drum filter conveyors are the premium solution for high-coolant-volume applications (machining centres using through-spindle coolant at 50–200 L/min) where coolant cleanliness directly affects tool life and surface finish quality. Coolant filtration to 50–200 µm is achievable with drum filter conveyors, removing the fine chip particles that cause accelerated cutting tool flank wear.

Screw (Auger) Chip Conveyor

Screw chip conveyors use a rotating helical auger inside a trough to move chips from multiple machine entry points to a central discharge location. The auger pushes chips forward regardless of chip size or shape up to the auger’s pitch diameter; chips that are smaller than the auger pitch move freely while the auger transports them. Screw conveyors excel at handling fine, granular, or powdery chips over long horizontal distances (up to 10 m) — they are used for long chip transfer from multi-machine cells to a central chip collection point. Screw conveyors are not suitable for long, stringy chips that wrap around the auger shaft; they are specified only for short-chip applications (cast iron, small turning swarf, grinding swarf).

Comparison Table: Chip Conveyor Types by Material

| Chip Type | Material Examples | Morphology | Recommended Conveyor |

| Long, stringy | Steel, stainless steel (turning) | Ribbons 50–300 mm | Hinge belt |

| Long, curly | Aluminium (milling) | Helical curls 10–100 mm | Hinge belt |

| Short, C-shaped | Steel (with chip breaker) | C-shape 5–20 mm | Hinge belt or scraper |

| Granular/fragite | Cast iron, brass | < 5 mm granules | Scraper or screw |

| Fine ferrous | Steel grinding | < 1 mm powder | Magnetic |

| Fine, all materials | Grinding, honing | Sub-mm powder | Drum filter |

| Mixed, remote transfer | Any material, long distance | Any | Screw (auger) |

Selecting the correct conveyor type is critical to ensure stable chip evacuation, prevent jamming, and minimize maintenance

Key Components of a Chip Conveyor System

Complete chip conveyor systems integrate the chip transport mechanism, the coolant drainage structure, the drive unit, and the coolant management subsystems.

Conveyor body and trough — Fabricated from 4–6 mm mild steel (painted) or 304 stainless steel (for corrosive coolant environments). The trough is the sealed enclosure that contains chips and coolant throughout the transport path. Drain apertures — perforated plates or wire mesh screens — are positioned along the inclined section for coolant drainage. Screen mesh size (typically 1–5 mm) balances drainage rate against fine-chip carryover into the coolant tank.

Hinge belt assembly — Steel plate links connected by precision-ground hinge pins (hardened 60–62 HRC for extended wear life). Belt width selection must match the machine chip pan outlet width plus 20 mm minimum clearance. Standard widths: 100, 150, 200, 250, 320, 400, 500 mm. Chain pitch (50 mm standard; 100 mm heavy-duty) determines the maximum chip size the belt can carry without jamming at the drive sprocket.

Drive unit — 0.25–1.5 kW three-phase motor with helical gearbox, direct-mounted to the conveyor head shaft. Motor is CNC-interlocked through the machine’s auxiliary output relay. Torque monitoring relay detects belt jam conditions and triggers alarm + stop before belt damage occurs. DNC Automation specifies Siemens motors with IP54 protection as standard for chip conveyor drive units.

Coolant tank — Integral coolant tank (50–500 L capacity) formed at the base of the conveyor body, below the chip inlet zone. Drain valve for periodic cleanout. Coolant level sensor (float switch) connected to coolant pump control. Secondary sump with baffle plate for fine swarf settling before pump suction.

Chip briquetter interface — High-volume machining operations generating 500+ kg/shift of chips benefit from chip briquetters that compress loose chips into dense pucks (5–10:1 compression ratio), increasing scrap metal value by 30–50% and reducing transport volume. DNC Automation integrates chip conveyors with chip briquetters in high-volume automotive machining cells.

──────────────────────────────────────────────────

Applications: Where Chip Conveyors Are Used in Malaysian Manufacturing

Chip conveyor applications in Malaysia concentrate in automotive machining, aerospace component manufacturing, die casting, and precision engineering.

Automotive Machining — Selangor

Selangor’s automotive machining sector — supplying machined components to Toyota Malaysia, UMW Toyota, Proton, Perodua, and their Tier-1 and Tier-2 suppliers — is the largest consumer of chip conveyor systems in Malaysia. Engine blocks (cast iron and aluminium), cylinder heads (aluminium), crankshafts (steel), transmission cases (aluminium die casting), and brake discs (cast iron) are all machined in high-volume, multi-pallet horizontal machining centre cells. Toyota and UMW are DNC Automation clients; DNC has engineered chip and coolant management systems for Toyota’s Selangor component manufacturing operations. Cast iron engine block machining produces 300–600 kg/shift of fragite swarf per machine — scraper chip conveyors with magnetic pre-separation remove cast iron swarf reliably across multi-machine cells.

Aerospace and Precision Engineering — Penang

Penang’s aerospace supply chain manufactures titanium, Inconel, and aluminium structural components for regional MRO (maintenance, repair, and overhaul) operators and Tier-2 global aerospace suppliers. Titanium machining generates fine, powdery chips with pyrophoric risk (titanium dust ignites at 250°C in air) — chip management protocols require magnetic conveyors for fine ferrous co-mingled particles, wet chip handling to suppress fire risk, and sealed collection bins with inert atmosphere for titanium swarf. DNC Automation engineers compliant chip management systems for Penang aerospace facilities under AS9100 quality management requirements.

Die Casting and Aluminium Machining — Selangor

Aluminium die casting machining facilities in Selangor produce long, curly swarf from CNC turning and milling of die-cast components (housings, brackets, engine mounts). Aluminium chips have a high coolant retention rate — loosely packed aluminium turnings can contain 30–50% coolant by weight. Hinge belt chip conveyors with extended inclined sections (to maximise coolant drainage time) recover 85–90% of carried coolant from aluminium swarf, delivering chips to briquetters that press the remaining wet chips into dry pucks suitable for direct re-smelting return to aluminium foundries.

CNC Precision Turning Shops — Penang and Selangor

Precision CNC turning shops operating Swiss-type automatic lathes, CNC turning centres, and multi-axis turn-mill machines produce high volumes of short-to-medium steel and stainless steel chips. Hinge belt conveyors sized for the individual machine footprint are the standard; for stainless steel machining (where chips have high work-hardening and spring back that can jam narrow belt widths), 200–250 mm minimum belt width is specified with 100 mm chain pitch to prevent chip packing at the drive sprocket. DNC Automation supplies chip conveyor systems to precision turning shops in Penang’s industrial parks as part of complete CNC cell automation packages.

Benefits of Chip Conveyors for CNC Machining Operations

Chip conveyor systems deliver four measurable productivity improvements that compound across every machine in a machining facility.

Machine uptime increase — Unmanaged chip accumulation in CNC machine enclosures causes three to five spindle stops per shift on high-removal-rate operations, each requiring 10–20 minutes of operator intervention to clear chips manually. A chip conveyor eliminates these stops, recovering 30–100 minutes of productive spindle time per shift per machine — equivalent to a 6–20% OEE improvement on a machine running a 16-hour day.

Cutting fluid cost reduction of RM 5,000–50,000/year per machine — Coolant recovery through the chip conveyor returns 80–90% of cutting fluid to the machine tank. At a coolant cost of RM 15–50 per litre (concentrate) and coolant tank volumes of 200–500 L, the annual coolant saving from 80% recovery versus no recovery is RM 7,000–40,000 per machine per year, depending on coolant type and machine throughput.

Operator safety improvement — Manual chip removal from CNC machines is one of the leading causes of laceration injuries in Malaysian manufacturing workshops. Sharp stringy steel and aluminium chips cause severe cuts through standard gloves; fine grinding swarf causes eye injuries. Chip conveyors eliminate the need for manual chip clearing between parts, reducing chip-related injuries by 70–90% in DNC Automation client facilities.

Scrap metal value recovery — Clean, dry chips (coolant-free) achieve scrap metal prices 30–50% higher than wet, mixed chips. A machining facility producing 5,000 kg/month of steel chips with chip conveyor-recovered dryness (< 2% coolant content) versus wet chips (15–20% coolant content) achieves additional scrap revenue of RM 3,000–8,000/month at current steel scrap prices in Malaysia.

How to Choose the Right Chip Conveyor for Your CNC Machining Cell

Selecting the correct chip conveyor requires matching conveyor type to chip morphology, sizing the conveyor capacity to chip generation rate, and specifying the coolant management subsystem for the machine’s coolant system.

Chip morphology is the primary selection criterion — Long stringy steel or aluminium: hinge belt. Small granular cast iron or brass: scraper or screw. Fine ferrous grinding swarf: magnetic. High coolant volume with fine chip contamination: drum filter. Long-distance multi-machine cell transfer: screw auger.

Chip generation rate sizes the conveyor — Chip volume per hour (calculated from material removal rate and chip density) must not exceed 60% of the conveyor’s rated chip carrying capacity. For high-volume operations, DNC Automation engineers specify 30% margin above peak chip rate to prevent conveyor overload during heavy-cut roughing cycles.

Machine geometry defines conveyor inlet and discharge dimensions — The chip conveyor must fit within the machine’s rear or side chip discharge opening (typically 150–400 mm wide × 100–200 mm high). Discharge height must clear the chip collection bin with a minimum 50 mm clearance above the bin’s full level.

Coolant system integration requires matching coolant tank volume, pump pressure, and filter screen size to the machine’s coolant specification. DNC Automation engineers review the CNC machine tool’s coolant specification sheet (delivered with the machine from the tool builder) before specifying coolant system integration parameters.

NIMP 2030 and SAG Grant eligibility — Chip conveyor systems integrated with Siemens PLC monitoring, coolant concentration automatic dosing, and OEE data reporting to factory SCADA qualify as automation upgrades under MIDA’s SAG Grant criteria. DNC Automation assists Malaysian machining facilities through the SAG Grant application process.

Frequently Asked Questions About Chip Conveyors

What type of chip conveyor is best for machining steel in a Malaysian automotive plant?

Hinge belt chip conveyors with 50–100 mm chain pitch and 200–320 mm belt width are the standard specification for steel machining in automotive environments. Steel chips from turning and milling operations are typically 10–80 mm long with C-shaped or helical morphology — hinge belt conveyors transport these chips reliably without wrapping. For machining operations generating stringy chips longer than 100 mm, a chip crusher (rotary or shredder type) mounted at the conveyor inlet reduces chip length before entry, preventing conveyor jamming.

How much coolant can a chip conveyor recover?

Well-specified chip conveyors with adequate inclined drain section length recover 80–90% of cutting fluid carried out of the machining zone with the chips. Drum filter chip conveyors achieve 90–95% coolant recovery. The remaining 5–20% is absorbed or trapped within the chip matrix and is recovered only by chip briquetting (which presses residual coolant out under 200–500 bar pressure). Total coolant recovery (conveyor + briquetter) can exceed 95% of all cutting fluid in the system.

Can a chip conveyor be retrofitted to an existing CNC machine in Malaysia?

Yes — chip conveyors are designed to retrofit to existing CNC machines through the machine’s rear chip discharge opening, which is a standard feature of all machining centres, turning centres, and grinding machines. DNC Automation engineers measure the machine’s discharge opening and internal chip pan geometry during a site survey, then designs a chip conveyor that fits within the existing machine footprint without modification to the machine structure. Retrofit installations are typically completed within 4–8 hours of machine downtime.

What is the maintenance requirement for a chip conveyor?

Chip conveyor maintenance includes weekly inspection of belt or chain wear and tension, monthly cleaning of drain screens and coolant filter elements, quarterly drive unit inspection and lubrication, and annual hinge belt pin and plate wear measurement. Belt or chain replacement intervals depend on chip abrasiveness and operating hours — cast iron granular chips wear hinge belt plates 3–4× faster than aluminium chips. DNC Automation provides maintenance contracts with quarterly service visits for chip conveyor systems installed in Malaysia.

How does a chip conveyor improve overall equipment effectiveness (OEE)?

Chip conveyors improve OEE through three of its six loss categories: unplanned downtime (eliminating chip jam stoppages), setup and adjustment time (eliminating manual chip clearing between parts), and process defects (preventing chip re-cutting that causes surface finish degradation and tool breakage). Combined, these OEE improvements typically add 5–20 percentage points to machining cell OEE, depending on the initial frequency of chip-related stoppages.

What chip conveyor types does DNC Automation supply and install in Malaysia?

DNC Automation (dnc-automation.com) supplies and installs all chip conveyor types — hinge belt, scraper, magnetic, drum filter, and screw auger — as part of complete CNC cell automation packages. DNC’s 35+ engineers design chip and coolant management systems for automotive machining, aerospace, die casting, and precision engineering applications, integrating Siemens PLC control with CNC machine interfaces for automated chip removal, coolant monitoring, and production data reporting. All systems are ISO 9001:2015 designed and installed. Get a Free Consultation to specify the right chip conveyor for your machining operation.

Conclusion

Chip conveyors are the most direct investment a Malaysian CNC machining operation can make to recover hidden productive time, reduce cutting fluid costs, and eliminate the operator safety risks associated with manual swarf management. For Selangor’s automotive machining sector, Penang’s aerospace precision engineers, and the growing precision engineering industry across Malaysia’s industrial parks, chip and coolant management is a productivity multiplier — not an afterthought.

DNC Automation (dnc-automation.com) — Malaysia’s No. 1 factory automation company since 2005, ISO 9001:2015 certified with 35+ engineers — designs, fabricates, and installs complete chip conveyor and coolant management systems for Malaysian CNC machining operations. DNC’s work with Toyota, Sony, and Hartalega demonstrates the breadth of machining automation expertise available. Talk to our engineers today for a Free Consultation and find out how your machining cell can qualify for the SAG Grant to fund a complete chip and coolant management upgrade.

Related reading: Explore DNC Automation’s complete machining automation solutions including Comau robot integration, Siemens CNC control upgrades, and automated quality inspection systems.

- 43 views

- 0 Comment

Recent Comments