Aluminium Profile Conveyor Systems: Modular Design for Automated Production Lines

In modern automated manufacturing, conveyor systems must be flexible, clean, and easy to integrate with automation equipment. Aluminium profile conveyors are designed to meet these requirements by combining modular aluminium extrusion frames with various conveying mechanisms, enabling efficient material handling in dynamic production environments.

What Is an Aluminium Profile Conveyor?

An aluminium profile conveyor is a conveyor system built on aluminium extrusion profiles that serve as the main structural frame. These profiles are precision-engineered with standardized slots, allowing conveyor components, accessories, and automation devices to be mounted easily without welding.

Unlike traditional steel-frame conveyors, aluminium profile conveyors emphasize modularity, flexibility, and clean design, making them ideal for modern automated production environments where layout changes, integration, and cleanliness are important.

Why Are Aluminium Profile Conveyors Popular in Modern Automation?

As factories move toward flexible manufacturing and Industry 4.0, conveyor systems must adapt quickly to changing processes. Aluminium profile conveyors support this shift by offering:

- Fast assembly and reconfiguration without structural modification

- Lightweight construction with sufficient rigidity for light to medium loads

- Clean, professional appearance suitable for modern production floors

These characteristics make aluminium profile conveyors a preferred solution in automation-focused facilities.

Why Are Aluminium Profile Conveyors Popular in Modern Automation?

How Does an Aluminium Profile Conveyor Work?

An aluminium profile conveyor functions as a structural platform that supports different conveying mechanisms:

- The aluminium frame provides rigidity and alignment

- Conveyor elements (belt, rollers, chain) are mounted directly to the profiles

- Motors, gearboxes, sensors, and guards are attached using standard slot connectors

This modular architecture allows engineers to design conveyors that are easy to assemble, adjust, and expand, while maintaining precise alignment and stable operation.

What Types of Aluminium Profile Conveyors Are Commonly Used?

Aluminium profile conveyors can be configured in several common forms:

- Aluminium Profile Belt Conveyors: Used for smooth, continuous transport of products. Ideal for assembly lines, inspection stations, and packaging operations where gentle handling and clean operation are required.

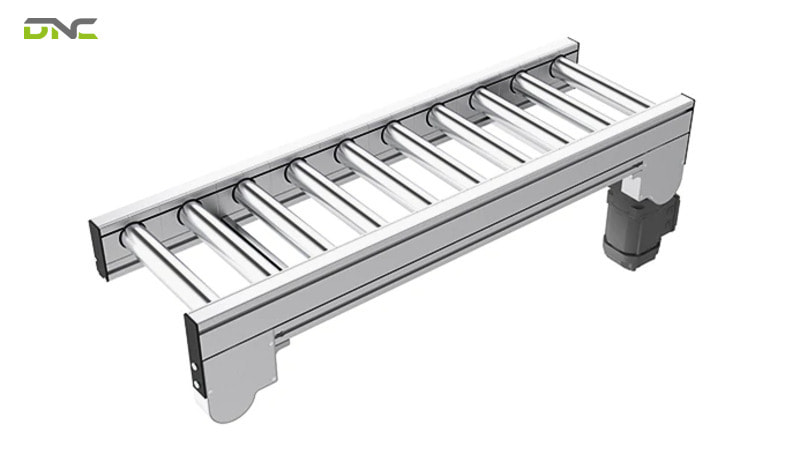

- Aluminium Profile Roller Conveyors: Suitable for cartons, totes, or pallets with flat bottoms. Often used in manual or semi-automated lines where accumulation and gravity flow are needed.

- Aluminium Profile Chain Conveyors: Designed for controlled positioning and indexing applications. Frequently used in automotive component assembly or workstation-based production.

- Modular Workstation Conveyors: Integrated with workbenches, fixtures, and operator stations to support ergonomic and flexible assembly processes.

What Types of Aluminium Profile Conveyors Are Commonly Used?

What Industries Commonly Use Aluminium Profile Conveyors?

Aluminium profile conveyors are widely used in industries that require precision, cleanliness, and flexibility, including:

- Electronics and semiconductor manufacturing

- Automotive component assembly

- Packaging, labeling, and inspection lines

- Pharmaceutical and clean manufacturing environments

Their modular nature makes them well-suited for facilities with frequent process changes.

What Are the Advantages of Aluminium Profile Conveyors?

Aluminium profile conveyors are widely used in modern automated factories because they offer a balance between structural strength, flexibility, and ease of integration. Compared to traditional welded steel conveyor frames, aluminium profile systems are designed to adapt quickly to changing production requirements while maintaining stable and reliable operation.

- Lightweight yet rigid structure: Aluminium profiles offer excellent strength-to-weight ratio, reducing installation effort while maintaining stability.

- High modularity and flexibility: Frames, supports, and accessories can be easily modified or expanded.

- Easy automation integration: Sensors, vision systems, robotics, and guarding can be mounted directly to profile slots.

- Clean design and corrosion resistance: Ideal for cleanrooms, pharmaceutical areas, and modern factory environments.

- Low maintenance requirements: No welding joints and standardized components simplify maintenance and adjustments.

What Are the Limitations of Aluminium Profile Conveyors?

Despite their advantages, aluminium profile conveyors are not suitable for all applications:

- Lower load capacity than steel-frame conveyors: Not ideal for heavy pallets or high-impact loads.

- Limited resistance to extreme environments: Harsh heat, heavy vibration, or abrasive conditions may require steel structures.

- Higher material cost compared to basic steel frames: Initial investment can be higher, though lifecycle cost is often lower.

Despite their advantages, aluminium profile conveyors are not suitable for all applications

How Does DNC Automation Deliver Aluminium Profile Conveyor Solutions?

DNC Automation delivers aluminium profile conveyor systems using a system integration approach:

- Detailed analysis of product flow and load conditions

- Engineering-driven frame and conveyor design

- Customized aluminium profile structures and accessories

- Integration with PLCs, sensors, robotics, and automation systems

- Professional installation, commissioning, and long-term support

This ensures each conveyor system is reliable, scalable, and optimized for real production conditions.

- 0 views

- 0 Comment

Recent Comments