Conveyor Metal Detectors: Types, Configuration, and System Integration

Conveyor metal detectors are essential inspection systems used to identify metal contaminants as products move through automated production lines. When properly integrated with conveyors and control systems, they help ensure product safety, equipment protection, and regulatory compliance without disrupting production flow. What Is a Conveyor Metal Detector and How Does It Work? A conveyor metal..

Read more- 0 views

- 0 Comment

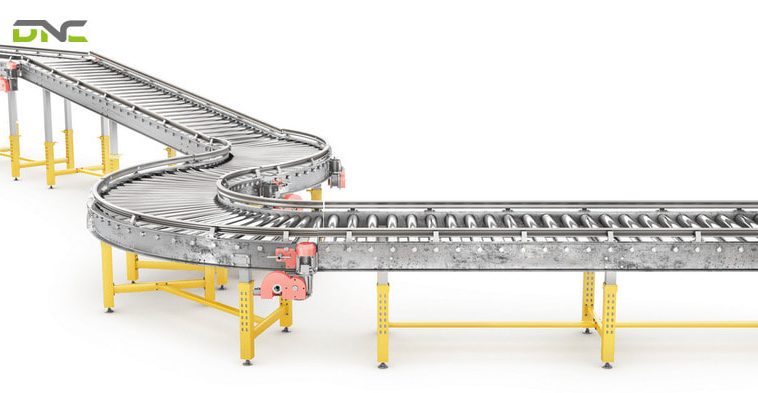

Roller Chain Conveyor Systems: Design, Types, and Industrial Applications

Roller chain conveyors are designed for transporting heavy and palletized loads in industrial environments where strength and load stability are critical. By using chain-driven rollers, these systems provide controlled movement and reliable positioning across automated production and material handling lines. What Is a Roller Chain Conveyor and How Does It Work? A roller chain conveyor..

Read more- 1 views

- 0 Comment

Timing Belt Conveyors: The Engineering Guide to Precision Indexing and Synchronous Flow

In this guide, DNC Automation breaks down the technical mechanics, component selection, and specialized applications of these high-performance synchronous systems to help you achieve zero-error material handling. What is a Timing Belt Conveyor and how does it differ from standard belt systems? A Timing Belt Conveyor (often called a Synchronous Belt Conveyor) represents a significant..

Read more- 0 views

- 0 Comment

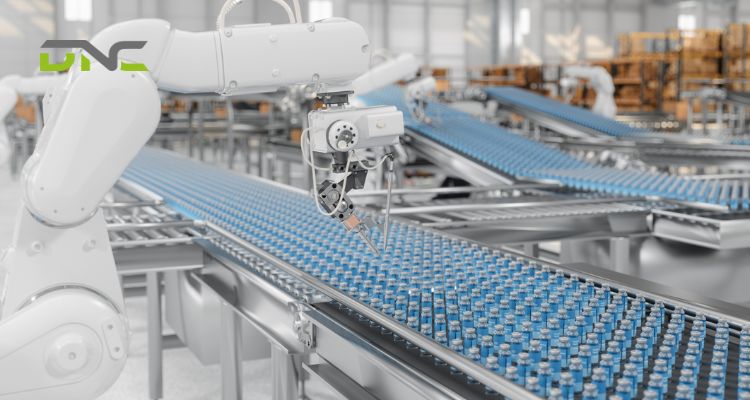

Motorized Conveyor Design and Operation in Automated Production Lines

Motorized conveyors are a core component of modern material handling and automated production systems. By providing controlled, powered movement, they enable consistent material flow, system synchronization, and reliable integration with automation technologies.\ What Is a Motorized Conveyor and How Does It Work? A motorized conveyor is a conveyor system that uses an electric motor to..

Read more- 0 views

- 0 Comment

Optimizing Industrial Flow: Why Flat Belt Conveyors are the Heart of Modern Automation

In the world of material handling, the Flat Belt Conveyor stands as the most versatile and widely utilized system. Whether it is moving micro-electronics or heavy boxed goods, this “workhorse” of automation provides a stable, reliable, and cost-effective solution for horizontal transport. What exactly is a Flat Belt Conveyor and why is it so widely..

Read more- 0 views

- 0 Comment

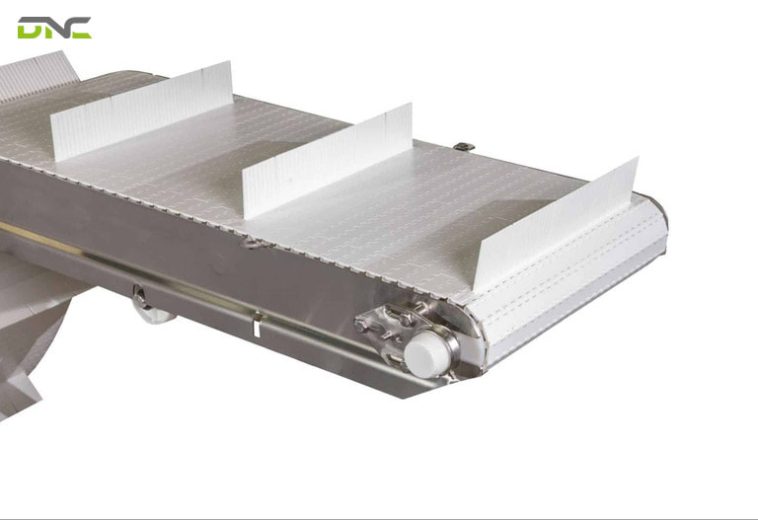

Cleated Conveyor Belt Explained: Types, Materials, Applications, and Design Considerations

Cleated conveyor belts are widely used in material handling systems where product stability, inclined conveying, and controlled material flow are required. By using raised cleats on the belt surface, they help prevent material rollback, reduce spillage, and maintain consistent positioning in automated production environments. This article explains how cleated conveyor belts work, the most common..

Read more- 2 views

- 0 Comment

Industrial Conveyor Belt Manufacturer for Automation Systems

Choosing the right industrial conveyor belt manufacturer is a major challenge for many factories and automation projects. Poor-quality belts, weak engineering support, and non-customized designs often lead to downtime, inefficiency, and costly rework. A reliable manufacturer must deliver more than belts—they must provide engineered solutions that integrate seamlessly into automated operations. What Is an Industrial..

Read more- 2 views

- 0 Comment

Conveyor Belt Rubber: Types, Properties & Uses

Premature belt wear, frequent downtime, and unexpected maintenance costs are common issues in conveyor systems. In many cases, the root cause is not the conveyor design, but the wrong conveyor belt rubber selection. Rubber quality directly impacts durability, grip, resistance, and system reliability. Understanding conveyor belt rubber materials, properties, and applications is essential for building..

Read more- 7 views

- 0 Comment

Airport Conveyor Belt Systems for Efficient Airports

Baggage delays, system congestion, and manual handling errors are common challenges in busy airports. When an airport conveyor belt system is poorly designed or outdated, it can disrupt baggage flow, increase operational costs, and negatively impact passenger experience. Modern airports require reliable, automated conveyor solutions to ensure smooth, continuous, and accurate baggage handling across all..

Read more- 1 views

- 0 Comment

Belted Conveyor Systems: Design, Applications, and Advantages in Automated Material Handling

Belted conveyors are a key component in modern material handling systems where product stability and smooth flow are essential. By using a continuous belt surface, these conveyors provide full product support, minimize damage, and ensure consistent movement throughout the line. What Is a Belted Conveyor and How Does It Work? A belted conveyor is a..

Read more- 1 views

- 0 Comment

Recent Comments