Automated Carton Packaging Systems

In Malaysia’s fast-evolving manufacturing landscape, efficiency, precision, and flexibility are more important than ever. As industries move toward digital transformation and Industry 4.0, automated carton packaging systems have become a critical investment for companies seeking to streamline operations, cut costs, and maintain consistent product quality.

These systems are redefining end-of-line packaging – ensuring that every product is packed safely, securely, and with minimal human intervention.

What Are the Components of Carton Packaging Systems?

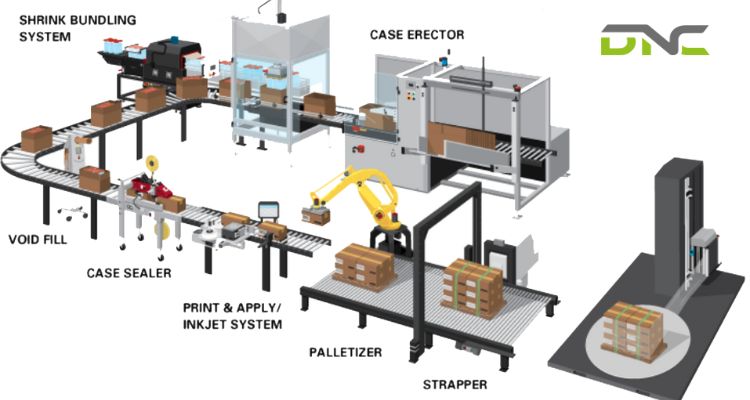

An automated carton packaging system is a fully integrated solution designed to form, load, and seal cartons with little or no manual handling. Typically, it includes three main modules:

- Carton erector – automatically forms flat cartons into boxes.

- Product inserter – loads items into the cartons accurately.

- Case sealer – closes and seals the cartons using adhesive tape or hot melt glue.

Working together as part of an end-of-line automation setup, these machines ensure smooth, high-speed packaging operations that improve consistency and reduce downtime. Modern systems also incorporate servo motors, machine vision, and PLC control to ensure precise synchronization and quality assurance.

Benefits of Automated Carton Packaging Systems

How Automated Carton Packaging Works?

Here’s how a typical automated carton packaging line operates:

- Carton Forming – Flat blanks are automatically erected into boxes.

- Product Loading – Products are positioned and inserted by mechanical or robotic arms.

- Closing and Sealing – The carton flaps are folded and sealed securely.

- Labeling and Inspection – Barcodes and labels are applied, and vision systems verify quality.

Advanced lines integrate robotic packaging arms, machine vision cameras, and PLC-based control systems that provide real-time monitoring and adaptive control for maximum efficiency.

Benefits of Automated Carton Packaging Systems

- Increased Efficiency and Throughput: Automation significantly reduces cycle time and human error. With continuous operation and optimized product handling, manufacturers achieve higher production throughput, faster changeovers, and minimal bottlenecks. This improvement translates directly into higher productivity, ensuring consistent output even under tight delivery schedules.

- Cost Savings and Labor Optimization: By automating repetitive packaging tasks, companies can reduce labor costs, minimize material waste, and lower energy consumption. Over time, the return on investment (ROI) becomes clear — fewer operators are needed, downtime is reduced, and production runs are more predictable.

- Improved Product Quality and Consistency: Automated systems maintain uniform packaging standards, ensuring each carton meets strict quality requirements. Features like automatic detection and defect rejection help eliminate inconsistencies, leading to fewer customer complaints and stronger brand reliability.

What Are The Types of Automated Carton Packaging Systems

Automated carton packaging systems vary by design and function, including horizontal, vertical, and robotic configurations. Each type offers unique advantages in speed, flexibility, and precision, helping manufacturers improve productivity, product consistency, and adaptability across food, pharmaceutical, and consumer goods industries.

Horizontal Carton Packaging Machines

Horizontal cartoners are widely used in the food, pharmaceutical, and consumer goods sectors. These systems load products horizontally into cartons, offering flexibility for various carton sizes and shapes. Their modular design supports quick changeovers, making them ideal for short product runs.

Vertical Carton Packaging Machines

Vertical cartoners handle powders, liquids, or small solid items, making them suitable for beverage, chemical, and FMCG industries. They excel in applications where gravity assists product loading, ensuring faster filling and reduced spillage.

Robotic and Custom-Integrated Systems

Modern packaging lines increasingly rely on collaborative robots (cobots) and smart vision-guided systems. These setups offer adaptability — capable of recognizing different product types and adjusting to new packaging formats in real-time.

Types of Automated Carton Packaging Systems

Integration with Industry 4.0 and Smart Factory Technologies

- IoT and Data Analytics in Packaging Lines: Today’s advanced packaging systems connect seamlessly with IoT-enabled sensors and data analytics tools. This allows manufacturers to perform predictive maintenance, monitor machine performance remotely, and make data-driven decisions that improve uptime and efficiency.

- Interfacing with MES, SCADA, and ERP Systems: To align with Malaysia’s Industry 4.0 roadmap, packaging lines must communicate effectively with higher-level systems like MES, SCADA, and ERP. Seamless data exchange ensures that production information flows from the shop floor to enterprise management, supporting full digital traceability and process optimization.

Integration with Industry 4.0 and Smart Factory Technologies

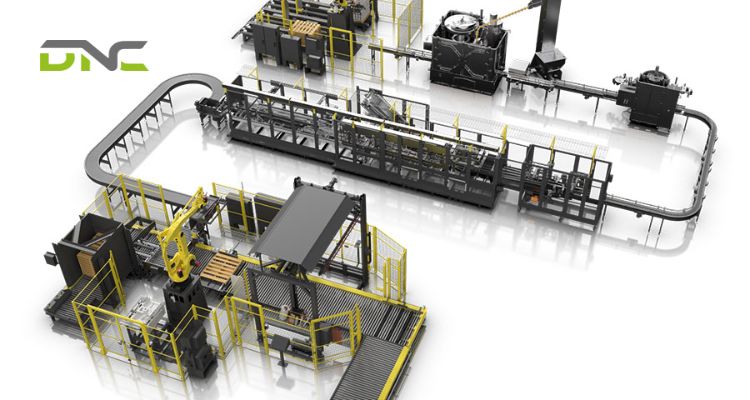

Why Choose DNC Automation as Your Automated Carton Packaging Systems Partner?

With over a decade of experience in end-of-line automation, DNC Automation is one of Malaysia’s leading integrators for automated carton packaging systems.

- Proven expertise: 10+ years of success in packaging automation, robotics, and material handling integration.

- Turnkey approach: From system design and simulation to installation and after-sales support, DNC provides complete, ready-to-run carton packaging solutions.

- Integration excellence: Seamless connection with conveyors, palletizers, vision systems, and warehouse management software for a unified, data-driven workflow.

- Local engineering support: Dedicated teams across Malaysia deliver quick response times, preventive maintenance, and on-site service.

- Industry versatility: Trusted by manufacturers in food, FMCG, pharmaceuticals, and electronics for reliable, high-performance packaging automation.

- 3 views

- 0 Comment

Recent Comments