Automatic Tablet Dispensing and Packaging System | Precision & Compliance in Pharma

An automatic tablet dispensing and packaging system streamlines the entire process — from counting and filling to sealing and labeling — with unmatched accuracy and hygiene. By integrating PLC and SCADA controls, these systems help manufacturers boost productivity, maintain compliance, and ensure every dose meets the highest quality standards.

What Is an Automatic Tablet Dispensing and Packaging System?

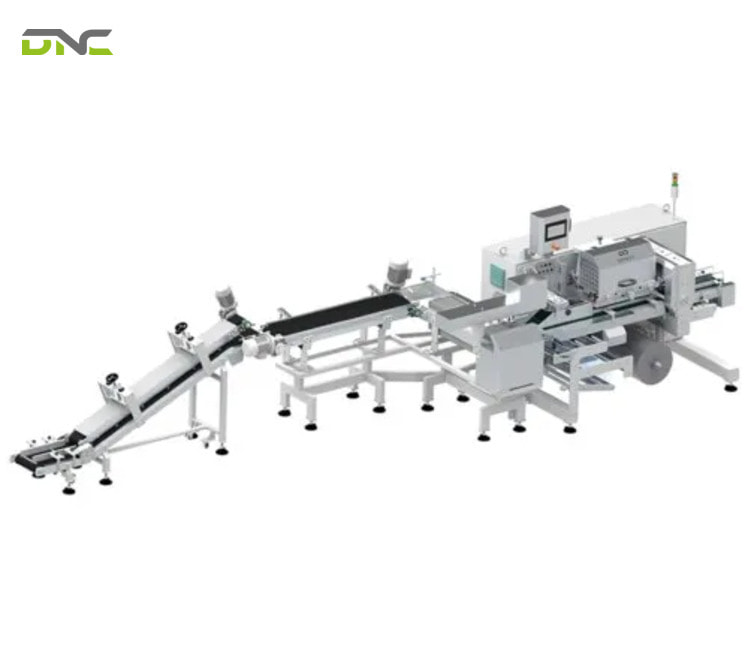

An Automatic Tablet Dispensing and Packaging System is an advanced solution designed to accurately count, fill, and pack tablets or capsules into various packaging formats — such as blisters, pouches, or bottles — without manual intervention.

This system combines precision dispensing technology, PLC control, and automated packaging modules to ensure each dose is measured, sealed, and labeled according to pharmaceutical standards.

In simple terms, it performs two key functions:

- Tablet dispensing – automatically counts and portions the required number of tablets per dose or container.

- Tablet packaging – seals and labels the product in a clean, traceable, and tamper-proof format.

Why Is Automation Essential in Tablet Dispensing and Packaging?

Automation plays a vital role in modern pharmaceutical manufacturing, especially in tablet dispensing and packaging processes where precision, hygiene, and compliance are paramount.

Here are the five key reasons automation is indispensable in this field:

- Improved Accuracy and Dosage Control: Automated systems utilize optical or vision-based sensors to count and fill tablets with exceptional precision. This ensures consistent dosage accuracy, eliminating the variability and potential errors found in manual operations.

Enhanced Contamination Prevention: Automation significantly reduces human contact with the product, minimizing the risk of contamination. - Increased Productivity and Efficiency: Automated tablet packaging systems can handle thousands of tablets per minute with consistent quality output. Integrated PLC and servo-driven controls allow continuous operation, minimizing downtime and maximizing production capacity.

- Comprehensive Traceability: With PLC/SCADA-based monitoring, every stage of the dispensing and packaging process is automatically recorded — including batch data, operator ID, timestamps, and machine settings.

5 key reasons automation is indispensable in this field

What Are the Main Types of Automatic Tablet Packaging Systems?

Automatic tablet packaging systems come in several configurations, each designed to handle specific dosage forms and production needs. Below are the most common types used in the pharmaceutical and nutraceutical industries:

Blister Packaging Machines

These machines create aluminum-plastic or aluminum-aluminum blisters that protect tablets from moisture, oxygen, and light. Blister packaging not only preserves product stability and shelf life but also allows for easy unit-dose dispensing, improving patient safety and convenience.

Pouch Packaging Machines

Ideal for powdered supplements or tablets sold in sachets or zip pouches, these systems automatically form, fill, and seal flexible film packaging. They are commonly used for nutraceuticals, single-dose tablets, or combination packs, offering compact and hygienic packaging with attractive presentation.

Bottle Filling & Capping Machines

These machines count and fill tablets into bottles, followed by automatic capping, labeling, and sealing. They are widely used for over-the-counter (OTC) and prescription medications, enabling fast and accurate bottle packaging with integrated serialization and labeling modules.

Stick Pack or Strip Machines

Designed for small single-dose applications, such as chewable tablets or effervescent tablets, stick pack and strip machines create individual packets that are portable and convenient. They provide precise dosing and are ideal for high-volume production of travel-size or sample-size pharmaceutical products.

4 common types used in the pharmaceutical and nutraceutical industries

How Do PLC and SCADA Enhance Tablet Packaging Automation?

Automation control systems like PLC (Programmable Logic Controller) and SCADA (Supervisory Control and Data Acquisition) play a central role in ensuring seamless, reliable, and compliant operations in tablet packaging lines.

- Centralized Control – The PLC coordinates all modules in the system, from tablet feeding and counting to sealing and labeling, ensuring synchronized motion and process accuracy.

- Data Logging – Production data such as batch numbers, timestamps, temperature, and machine settings are automatically recorded for traceability and audit purposes.

- Alarm & Fault Detection – The system detects faults or irregularities in real time, triggering alarms to prevent product defects and minimize downtime.

- Integration Capability – PLC and SCADA systems can easily integrate with MES, ERP, or pharmaceutical serialization platforms, enabling full production transparency.

- Compliance Support – Automated data collection and access control features support 21 CFR Part 11 compliance for secure and validated electronic recordkeeping.

How Can Integration and Maintenance Maximize Long-Term System Performance?

Ensuring long-term system performance requires careful integration and proactive maintenance strategies:

- System Integration – The tablet dispensing and packaging system is integrated into the overall production line, connecting upstream processes (mixing, compression, coating) and downstream logistics.

- Preventive Maintenance – Regular checks on sensors, conveyors, and vision systems help prevent unexpected breakdowns and maintain consistent performance.

- Software & Firmware Updates – Keeping PLC and SCADA software up-to-date ensures enhanced control logic, cybersecurity, and system stability.

- IoT & Predictive Maintenance – Smart IoT sensors enable remote monitoring of machine health, vibration, and temperature, supporting predictive maintenance that minimizes downtime.

Ensuring long-term system performance requires careful integration and proactive maintenance strategies

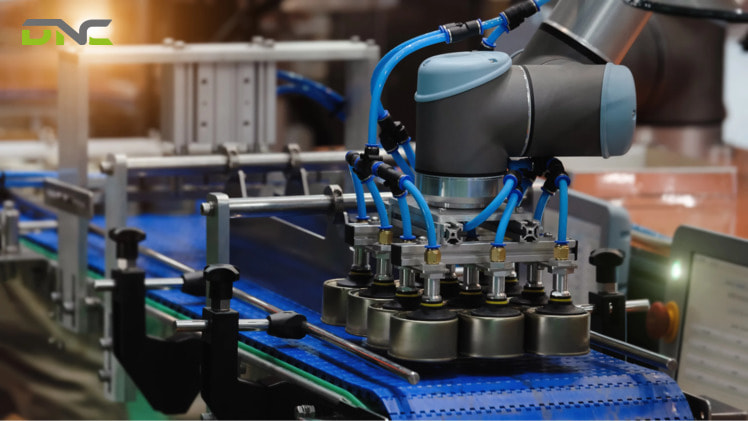

Why Choose DNC Automation for Tablet Dispensing & Packaging Solutions?

DNC Automation is a trusted expert in pharmaceutical automation, offering end-to-end integration of PLC, SCADA, robotics, and vision systems. With extensive experience in GMP-, CE-, and FDA-compliant facilities, DNC delivers customized automation solutions that meet the highest industry standards.

Our services include consultation, design, installation, calibration, and operator training, ensuring smooth project execution and long-term operational reliability. At DNC, we commit to precision, safety, efficiency, and transparent traceability — the pillars of modern pharmaceutical production.

Conclusion

Automatic tablet dispensing and packaging systems represent a crucial step in the evolution of pharmaceutical manufacturing.

They ensure precision dosing, contamination control, and global regulatory compliance while significantly boosting productivity and product quality. Investing in automation isn’t just about technology — it’s about building a safer, smarter, and more sustainable pharmaceutical future.

- 25 views

- 0 Comment

Recent Comments