What is Buffer Conveyor? Features and applications in factory automation

Buffer Conveyor is an effective automation solution that optimizes the transportation and temporary storage of products in the factory. With conveyor lengths ranging from 2m to 30m, widths from 300mm to 1200mm, and load capacities up to 500kg/m, the system supports flexible operating speeds from 5m/min to 30m/min, helping to maintain continuity and minimize bottlenecks in production.

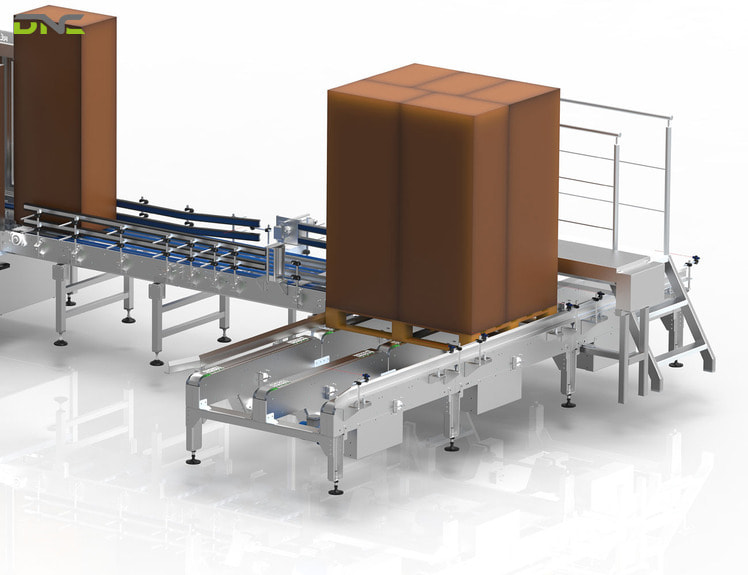

What is a buffer Conveyor?

A Buffer Conveyor is a conveyor system used to create a buffer space, allowing temporary storage of products during the manufacturing process.

It acts as a “buffer” between stages in the production line, allowing parts or products to be temporarily held without interrupting the overall process.

Buffer Conveyor Specifications

- Size (Length x Width x Height): 2000mm x 1200mm x 1000mm (Can be changed according to business needs)

- Conveyor material: Stainless steel or 304 stainless steel

- Maximum load: 50kg – 500kg

- Speed: 5m/min – 20m/min

- Power: 0.25kW to 5.5kW

- Heat resistance: 80°C to 100°C, some types can withstand temperatures up to 150°C

- Dust and water resistance: Systems with IP54 to IP67 index (dust and water resistance according to international standards)

- Warranty: 12 months

What are the benefits of using Buffer Conveyor in factory automation?

- Reduce congestion: Buffer conveyor helps to pause products during transportation, avoiding congestion in the production line when a stage is slow or stopped. This helps maintain continuity throughout the entire process.

- Increase efficiency and productivity: Buffer conveyor helps to minimize machine downtime due to parts needing more time to process. As a result, the working efficiency of the production system is improved.

- Flexible adjustment ability: Buffer conveyor helps the factory to flexibly adjust the speed and operating time of different parts in the line without affecting each other.

- Easy integration with other automation systems: Buffer conveyors can be connected to other automation devices such as robots, dynamic conveyors, helping to enhance the automation capability of the entire factory.

- Optimize storage space: This system allows temporary storage of products while maintaining continuous operation of other parts in the chain, increasing the efficiency of the entire process.

Thanks to the above benefits, the use of buffer conveyor helps factories automate and optimize production processes, increase efficiency and minimize operating costs.

Advantages of Buffer Conveyors

What are the considerations for choosing the right Buffer Conveyor for your factory?

To choose the right Buffer Conveyor for your factory, you need to consider a number of important factors to ensure the system operates efficiently and is suitable for your factory’s production requirements.

- Determine the product type: Products with different sizes, weights or shapes will require different types of conveyors.

- Determine the product volume: If your factory has large-scale production, you need to choose a buffer conveyor that can store and transport a large volume of products.

- Size of the factory: Measure the available space in the factory to ensure that the buffer conveyor system can be installed without affecting other lines.

- Ability to integrate with other systems: If your factory uses automation systems such as robots or control systems, make sure that the buffer conveyor can easily integrate with these devices.

- Calculate investment costs: Consider the total investment cost, including installation and maintenance costs.

- Choose a reputable supplier: They will provide solutions that suit the specific needs of the factory and support warranty and maintenance services.

What are the considerations for choosing the right Buffer Conveyor for your factory?

How are Buffer Conveyors used in different industries?

Buffer Conveyors can be used in many different industries due to their ability to increase operational efficiency and optimize production processes. Here are some specific applications of Buffer Conveyors in different industries:

- Automotive manufacturing industry: Buffer Conveyors help create space between production stages, minimizing bottlenecks when parts are not ready to continue the production process.

- Food and beverage industry: Buffer Conveyors can be used to regulate the transportation of products such as cans, bottles, packaging, or food in packaging and processing processes.

- Electronics and components industry: The conveyor helps regulate electronic components or small parts in production and assembly lines.

- Logistics and distribution industry: Buffer Conveyors are used in distribution and warehousing systems, helping to regulate the movement of goods between stages of the order processing process.

Buffer Conveyors can be used in many different industries due to their ability to increase operational efficiency and optimize production processes.

Are Buffer Conveyors Expensive or Cheap?

The price of Buffer Conveyors on the market usually ranges from $10,000 to $50,000. However, this price can vary depending on the following factors:

- System size: Large, long conveyor systems or those with high load capacity will cost more.

- Material: Materials such as stainless steel, PVC, or rubber will increase the cost. Stainless steel, because of its durability and corrosion resistance, is often more expensive than other materials.

- Motor power: Systems with large motor power (from 5.5kW to 15kW) will cost more than systems with lower power.

- Features and technology: Conveyor systems that integrate modern technology such as PLC, smart sensors, and automation capabilities will increase the price.

To know the exact price of Buffer Conveyor for your needs, you should contact the supplier directly for advice and detailed quotation.

The price of Buffer Conveyors on the market usually ranges from $10,000 to $50,000.

Where to buy reputable automatic buffer conveyor lines?

If you are uncertain about where to purchase a buffer conveyor, DNC Automation is an excellent option for you. Many customers have trusted DNC to provide automation solutions in the production process and have had positive experiences because:

- DNC is a leading technology, automation, and engineering company in Malaysia with over 15 years of experience in the field of automation

- System integration machinery, Internet of Things (IoT), Industry 4.0, and WinCC Scada System

- Diverse designs and sizes are suitable for many domestic and foreign houses. The equipment is 100% genuine and imported from Malaysia.

Please contact us via the hotline below if you have any questions about the product, we are happy to answer you!

- 103 views

- 0 Comment

Recent Comments