Mini-Load ASRS: Automated Storage Solutions 2026

Mini-Load ASRS are automated systems designed to handle totes, trays, and small containers, making them ideal for warehouses managing high SKU volumes and frequent picking operations. Unlike pallet-based Unit-Load ASRS, these systems maximize vertical space and ensure precision through computer-controlled storage and retrieval processes. Operating on a goods-to-person (G2P) principle, Mini-Load ASRS automatically deliver items..

Read more- 8 views

- 0 Comment

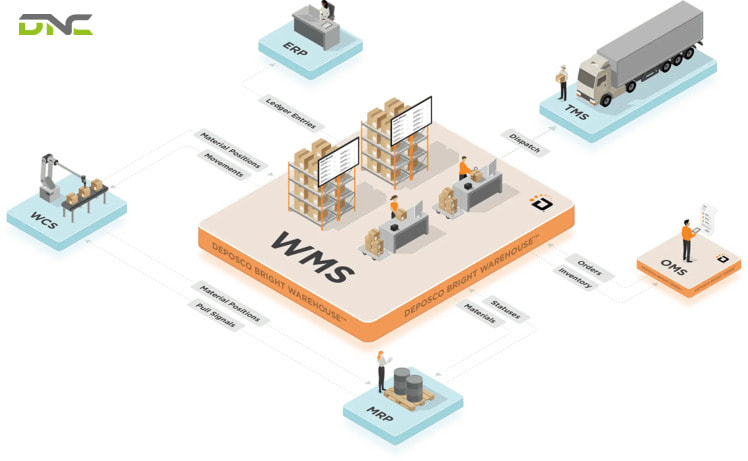

Top 5 Warehouse Management Systems 2026

Warehouse management systems (WMS) play a key role in optimizing modern supply chains. This article by DNC Automation will summarize the top 5 WMS software in 2025, helping businesses improve operational efficiency, save costs and control inventory more accurately than ever. What is Warehouse Management System (WMS)? Warehouse Management System (WMS) is a software system..

Read more- 18 views

- 0 Comment

Automated Palletizer: Boosting Efficiency and Safety in Manufacturing

An automated palletizer is a machine designed to stack goods onto pallets in a structured pattern for easier handling, storage, and shipment. Instead of relying on manual labor, these systems use robotic or mechanical technology to automate the palletizing process — ensuring faster and more consistent results. What Are the Benefits of Automated Palletizers for..

Read more- 0 views

- 0 Comment

Data-Driven Warehouse: Everything You Need To Know

Data-Driven Warehouse Management is a strategic operational approach that utilizes warehouse data analytics and technology to base decisions on real-time insights rather than intuition or historical guesswork. It involves implementing an intelligent warehouse system where every process, from inventory reception to final dispatch, is tracked, measured, and optimized using data. This forms the foundation of..

Read more- 0 views

- 0 Comment

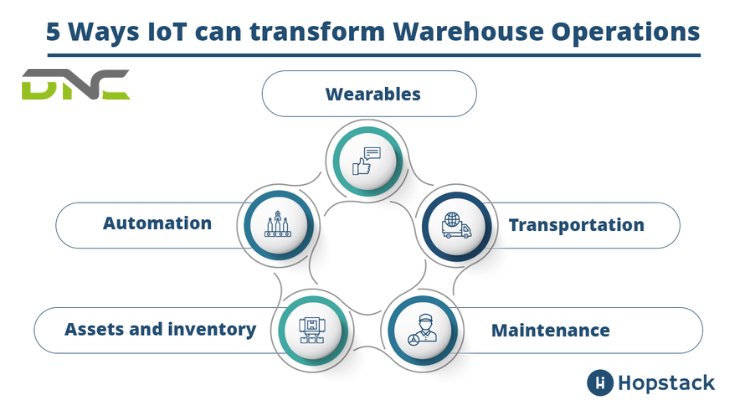

IoT in Warehouse Management: Smart Solutions for Your Warehouse

The Internet of Things (IoT) in a warehouse refers to a network of physical objects—assets, equipment, inventory, and environment equipped with sensors, software, and connectivity to collect and exchange data in real-time. This network transforms a traditional facility into a smart warehouse in Malaysia by enabling machine-to-machine (M2M) interaction and creating a connected logistics ecosystem…

Read more- 36 views

- 0 Comment

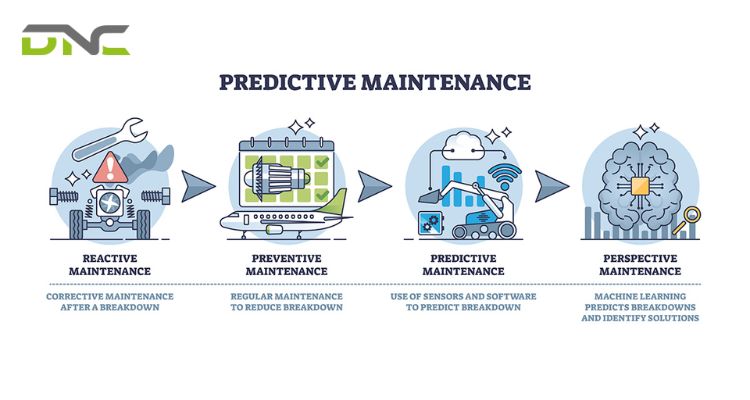

Predictive Maintenance: The Future of Smart Warehouses

Predictive maintenance is reshaping how warehouses operate. As facilities become smarter and more connected, predictive maintenance allows businesses to predict equipment failures before they occur ensuring seamless operations, higher productivity, and reduced costs. This technology-driven approach is quickly becoming the foundation of smart warehouse automation, combining IoT sensors, data analytics, and real-time monitoring to maximize..

Read more- 6 views

- 0 Comment

Warehouse Inventory Accuracy: Enhancing Efficiency in Malaysian Warehousing

Warehouse Inventory Accuracy is a critical Key Performance Indicator (KPI) that measures how closely the quantity and location of physical inventory on hand match the recorded data in your inventory management system (such as a WMS). High accuracy means minimal difference between the expected stock count and the actual stock count, ensuring warehouse data integrity..

Read more- 3 views

- 0 Comment

Automated Pallet Storage: Modern Warehousing Systems in Malaysia

An Automated Pallet Storage System is a sophisticated solution designed to automatically store and retrieve palletized goods with minimal or no human intervention. It defines the next generation of pallet storage automation by integrating physical infrastructure with advanced software controls. Its primary role in warehouse automation and logistics is to manage high volumes of stock,..

Read more- 3 views

- 0 Comment

Shuttle-Based ASRS: Revolutionizing Automated Warehousing in Malaysia

Shuttle-Based ASRS is transforming warehouse operations in Malaysia through intelligent automation and high-speed material handling. Using autonomous shuttles and vertical lifts, this system enables efficient multi-level storage, rapid retrieval, and precise inventory control. It maximizes space utilization while reducing labor dependency, making it ideal for industries facing workforce shortages and rising logistics costs. As Malaysia..

Read more- 24 views

- 0 Comment

Unit-Load ASRS Systems: Transforming Industrial Storage and Logistics

Malaysia’s manufacturing and logistics sectors are experiencing a significant transformation as businesses embrace warehouse automation technology to remain competitive in the global market. Unit-load Automated Storage and Retrieval Systems (ASRS) have emerged as a cornerstone solution for companies seeking to optimize space utilization, reduce operational costs, and improve inventory accuracy. This comprehensive guide explores how..

Read more- 10 views

- 0 Comment

Recent Comments