Conveyor Belt Motors: Types, Selection & Efficiency

Many conveyor systems struggle with inconsistent speed, excessive energy consumption, frequent breakdowns, or limited automation compatibility. In most cases, these problems stem from an unsuitable or poorly matched motor rather than the conveyor structure itself. Conveyor belt motors are the driving force behind material handling performance, directly influencing throughput, reliability, and operating costs. Selecting the right motor is essential for achieving stable operation, efficient power usage, and long-term system scalability.

This article provides a complete overview of conveyor belt motors, helping engineers and decision-makers understand their function, compare options, and make informed selection decisions.

What Are Conveyor Belt Motors?

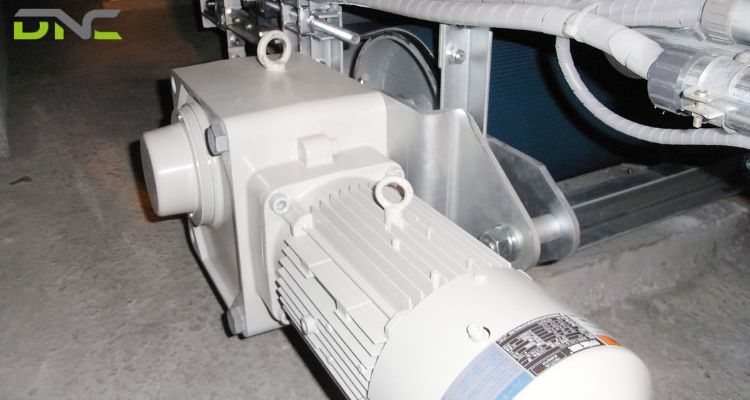

Conveyor belt motors are electric motors specifically designed to drive conveyor systems by converting electrical energy into mechanical motion. Their primary function is to generate the torque and rotational speed required to move conveyor belts under varying load conditions. These motors are typically integrated with gearboxes, pulleys, and control components to ensure smooth and controlled material flow.

Depending on the application, conveyor belt motors may operate continuously or intermittently and can be configured for fixed or variable speed. Their design plays a critical role in system efficiency, durability, and compatibility with modern automation environments.

How Conveyor Belt Motors Work

Conveyor belt motors operate by producing rotational motion that drives a pulley or roller connected to the conveyor belt. This motion transfers force along the belt surface, enabling consistent material movement across the system.

Understanding the operating mechanism of conveyor belt motors provides a foundation for evaluating motor performance, control options, and long-term reliability.

- Electrical-to-mechanical energy conversion: The motor uses electromagnetic interaction to convert electrical input into rotational force. The efficiency of this conversion affects power consumption, heat generation, and overall performance during continuous operation.

- Torque transmission to the conveyor system: Torque generated by the motor is transmitted through a shaft or gearbox to the conveyor pulley. Adequate torque is essential for smooth start-up, load handling, and preventing belt slippage.

- Speed regulation and control: Motor speed can be regulated through controllers or variable frequency drives, allowing the conveyor to adapt to changing production demands without mechanical stress.

Common Types of Conveyor Belt Motors

Different conveyor applications require different motor technologies based on load characteristics, speed control requirements, and automation integration.

Each motor type offers unique advantages, making it important to understand how they differ before selecting a solution.

- AC Motors: AC motors are widely used in conveyor systems due to their robustness and cost efficiency. They are well-suited for continuous-duty applications where stable operation is required. When paired with variable frequency drives, AC motors can deliver flexible speed control and improved energy efficiency.

- DC Motors: DC motors provide high starting torque and precise speed control. They are commonly used in conveyors that require frequent speed adjustments or smooth acceleration. However, DC motors generally require more maintenance compared to AC motors.

- Gear Motors: Gear motors combine an electric motor with an integrated gearbox to deliver high torque at reduced speeds. They are ideal for heavy-load conveyors, inclined systems, and applications where compact installation is required.

- Servo Motors: Servo motors offer high precision, fast response, and accurate positioning. These motors are commonly used in automated conveyor systems that require synchronization with robotics, sensors, or advanced control platforms.

Key Factors When Selecting Conveyor Belt Motors

Choosing the right conveyor belt motor directly impacts system performance, energy consumption, and maintenance costs. Motor selection should always be based on real operating conditions rather than nominal power ratings alone.

- Load capacity and torque requirements: Accurate load calculations ensure the motor can handle start-up conditions and peak loads without strain. Undersized motors risk failure, while oversized motors lead to unnecessary energy waste.

- Speed range and control needs: Conveyors that require variable speed operation benefit from motors compatible with VFDs or digital controllers. This improves process flexibility and product handling accuracy.

- Duty cycle and operating conditions: Motors must be rated for continuous or intermittent operation and be suitable for environmental factors such as dust, humidity, or temperature variations.

- Energy efficiency and lifecycle cost: High-efficiency motors reduce power consumption and operating expenses while extending service life through lower heat generation.

Conveyor Belt Motors Comparison

Understanding the differences between motor types helps system designers select the most appropriate option for their application.

The following comparison highlights key performance characteristics to support informed decision-making.

| Comparison Criteria | AC Motor | DC Motor | Gear Motor | Servo Motor |

|---|---|---|---|---|

| Speed Control | Moderate | Excellent | Moderate | Very high |

| Torque Output | Medium | High | Very high | High |

| Maintenance Needs | Low | Medium | Low | Medium |

| Energy Efficiency | High | Medium | High | High |

| Automation Compatibility | Good | Good | Very good | Excellent |

Energy Efficiency and Cost Optimization

Energy efficiency is a major consideration for conveyor systems that operate for long hours or under continuous load. Optimizing motor efficiency reduces electricity consumption while improving system stability and sustainability.

- Using variable frequency drives: VFDs allow conveyor belt motors to operate at optimal speeds based on actual demand, significantly reducing energy usage during partial load or idle conditions.

- Selecting premium-efficiency motors: High-efficiency motor designs minimize electrical and mechanical losses, lowering heat generation and reducing cooling and maintenance requirements.

- Improving mechanical transmission efficiency:Proper alignment, lubrication, and gearbox selection reduce friction losses and improve power transfer from motor to conveyor belt.

Why Are Conveyor Belt Motors Essential in Automation Systems?

Conveyor belt motors play a critical role in determining the effectiveness of automated material handling systems. Reliable motor performance ensures smooth coordination between conveyors, control systems, and downstream processes.

- Process synchronization Motors enable precise coordination between conveyors, sorting systems, and robotic equipment.

- System scalability: Automation-ready motors support future system upgrades without major mechanical or electrical redesigns.

- Consistent material flow: Stable motor operation reduces product damage and maintains predictable throughput across the production line.

Why Is DNC Automation a Trusted Partner for Conveyor Belt Motors?

DNC Automation is a trusted partner for conveyor belt motors, providing reliable solutions designed to meet modern automation requirements. With strong technical expertise, DNC Automation supports motor selection, system integration, and performance optimization to ensure long-term efficiency and operational reliability.

Selecting the right conveyor belt motor is essential for achieving efficient, reliable, and scalable automation systems. DNC Automation delivers expert guidance and proven conveyor motor solutions tailored to real operational demands.

Contact us now to discuss your conveyor belt motor requirements and enhance your automation performance.

- 13 views

- 0 Comment

Recent Comments