Conveyor Belt Scraper Systems: Engineering Analysis & Selection Guide

Material carryback is the silent enemy of conveyor efficiency, leading to equipment wear and high cleaning costs. A conveyor belt scraper is your first line of defense, essential for removing debris and extending belt life. In this guide, DNC Automation explores the various scraper types and materials to help you optimize your material handling system for peak performance.

What is the true cost of “Carryback” in your conveyor system?

In industrial material handling, Carryback is the residual material that fails to discharge at the head pulley and remains stuck to the belt. While it may seem like a minor nuisance, the technical implications are severe:

- Abrasive Wear: Carryback acts like sandpaper, grinding down return rollers, idlers, and the belt’s bottom cover.

- Belt Mistracking: Material buildup on return rollers creates an uneven diameter, forcing the belt to drift sideways, leading to edge damage and structural collisions.

- Operational Loss: Statistics show that carryback can account for up to 1-3% of total material loss. Over a year, this represents a significant hit to the bottom line.

- Safety Hazards: Accumulation under the conveyor creates “slip and trip” zones and, in some industries, poses a significant combustible dust explosion risk.

Why is a Multi-Stage Cleaning System necessary for 99% efficiency?

One scraper is rarely enough. To achieve maximum cleanliness, DNC Automation engineers a multi-stage approach based on the physics of the belt path:

A. The Primary Scraper (Pre-Cleaner): The “Peeler”

- Location: Mounted on the face of the head pulley, just below the material trajectory (usually at the “3 o’clock” or “4 o’clock” position).

- Physics: It uses a “Peeling” action. It is designed to remove the high-volume bulk (60-70% of material) before the belt leaves the pulley.

- Design Fact: The blade is usually made of a flexible polymer to prevent damage to the belt during high-impact discharge.

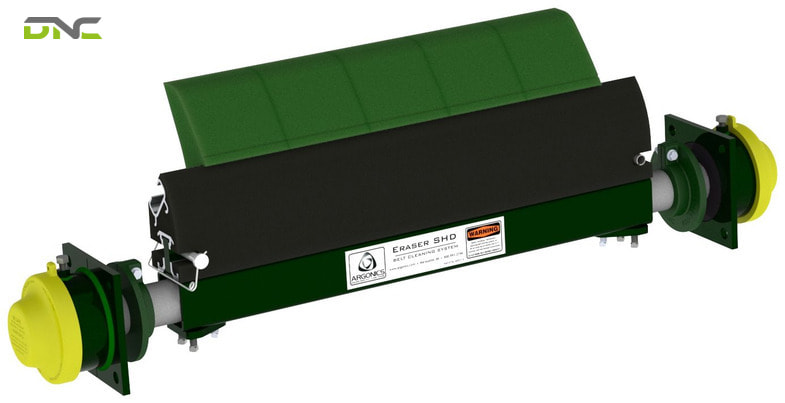

B. The Secondary Scraper: The “Polisher”

- Location: Positioned just behind the head pulley, where the belt is flat.

- Physics: It uses a “Scraping” action. This scraper is designed to remove “fines”—the microscopic, sticky, or wet particles that the primary scraper missed.

- Design Fact: It often utilizes harder materials like Tungsten Carbide to provide a precise, razor-sharp edge for “shaving” the belt surface clean.

C. The V-Plow (Internal Scraper): The “Protector”

- Location: Installed on the clean side (inside) of the belt, right before the tail pulley.

- Purpose: It prevents “stray” material (rocks, debris) from falling onto the inside of the belt. If a rock gets trapped between the belt and the tail pulley, it acts like a punch-press, potentially creating a hole in your expensive belt.

What is the true cost of “Carryback” in your conveyor system?

Material Science: How to choose the right blade for your scraper?

The efficiency of a conveyor belt scraper is dictated by the complex interaction between the blade material and the belt’s surface energy. Selecting the wrong material can either lead to poor cleaning performance or, worse, permanent damage to the belt cover.

- Polyurethane (PU): Typically featuring a hardness of 80-90 Shore A, this material offers a low friction coefficient and high impact resistance. It is engineered to be “belt-friendly” or sacrificial, meaning the blade wears down before the belt does, making it the ideal choice for primary scrapers and systems utilizing mechanical fasteners (clips).

- Tungsten Carbide: Known for its extremely high hardness and wear resistance, these blades maintain a sharp cleaning edge significantly longer than polymers. They are the premier choice for high-speed belts and highly abrasive materials like glass, iron ore, or granite; however, they must only be used on vulcanized (seamless) belts to avoid damaging mechanical joints.

- UHMW-Polyethylene (UHMW-PE): This material provides excellent chemical resistance and zero water absorption, which prevents wet or “tacky” materials from adhering to the blade. It is specifically designed for handling sticky food products or corrosive chemical substances where maintaining a non-stick surface is critical for hygiene and performance.

- Stainless Steel: Offering superior corrosion resistance and meeting stringent sanitary standards, these blades are essential for pharmaceutical and food-processing environments. They provide a rigid, durable edge that can withstand frequent high-pressure washdowns and exposure to aggressive cleaning agents without degrading.

- Ceramic Tipped Blades: Designed for extreme abrasion environments, ceramic inserts provide an incredibly long service life in wet and slurry conditions. They offer a middle ground between the flexibility of polymers and the extreme rigidity of carbide, often used in specialized secondary cleaning applications.

Selecting the wrong material can either lead to poor cleaning performance or, worse

The Tensioning Mechanism: Why “Set and Forget” is a myth?

The most common cause of scraper failure is loss of tension. As a blade wears down, the gap between the blade and the belt increases.

- Spring Tensioners: The most common system. They use mechanical spring pressure to push the blade upward. They require periodic manual adjustment as the spring loses its “stretch.”

- Air/Pneumatic Tensioners: Used in high-end automation. These systems use a constant air bag or cylinder to maintain identical pressure regardless of blade wear.

- DNC Engineering Tip: Over-tensioning is as bad as under-tensioning. Excessive pressure creates friction heat, which can “glaze” the belt surface, making it brittle and prone to cracking.

Why “Set and Forget” is a myth?

Why partner with DNC Automation for your cleaning solutions?

At DNC Automation, we integrate “Maintenance 4.0” into our solutions. We don’t just bolt a piece of plastic to your conveyor; we analyze the belt speed, material moisture content, and pulley diameter to provide a custom-engineered cleaning solution.

Our scrapers are designed for Rapid Blade Change (RBC). We ensure that your maintenance team can swap out a worn blade in under 10 minutes, minimizing downtime and ensuring your automation line never loses its momentum.

- 13 views

- 0 Comment

Recent Comments