Overview of Hopper Conveyor: Definition, Structure, Cost, and Industrial Application

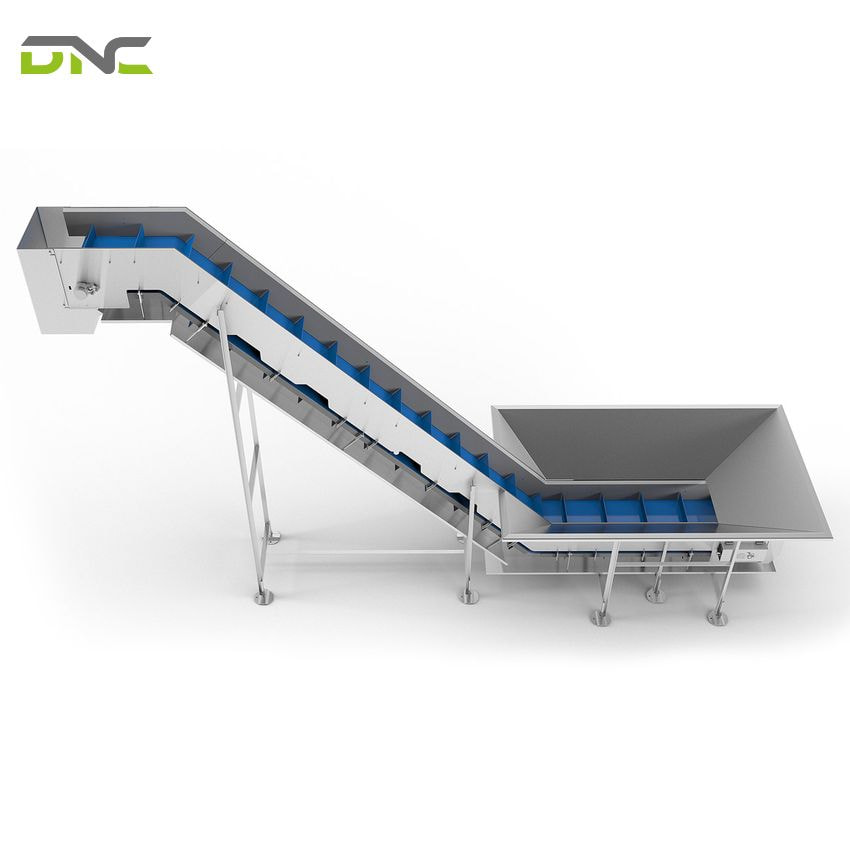

What is a hopper conveyor? A hopper conveyor is a type of material handling equipment used to store, transport, and control the flow of bulk materials. It essentially combines two main components: a hopper (a funnel-shaped container for temporary storage) and a conveyor system, usually a screw or chain, to move the material further.

Hopper conveyors are widely used in various industrial fields, such as food production, grain, pellets, and powders, or construction fields, such as sand, coal, and cement. By allowing the storage and feeding of bulk materials at a controlled rate, hopper conveyors improve the line’s efficiency and minimize waste.

How is a hopper conveyor built?

Although the design of a hopper conveyor can vary depending on the application, most systems follow a basic structure that includes the following components:

- Hopper: The hopper is typically made of stainless steel or mild steel and is shaped like an inverted pyramid or cone. The hopper is responsible for storing the material and guiding it down the conveyor system via a conveyor belt.

- Conveyor system: Attached below the hopper is the conveyor mechanism, which can be a screw conveyor, belt conveyor, or drag chain conveyor depending on the plant’s needs

- The frame is used to hold the hopper and conveyor in place. They are often modular for easy transportation and installation.

- The control system on the hopper conveyor can include a PLC-based control system to regulate the speed, flow, or discharge time of the material.

- Discharge port: A manhole cover or valve is usually installed at the bottom of the hopper to control the amount of material allowed to flow onto the conveyor at any given time.

What industries commonly use hopper conveyors?

What industries commonly use hopper conveyors?

Thanks to its unique design and ability to handle bulk solids effectively, hopper conveyors play an important role in many industries, some of which are notable:

- Agriculture: hopper conveyors support the process of transporting and loading seeds and grains accurately. In addition, the equipment will control the flow of raw materials well, minimize loss and optimize performance in mixing or bagging stations

- Mining and quarrying: The equipment is responsible for moving gravel, ore, and coal from the mining point to the processing area. The hopper conveyor can operate continuously with large loads without being worn out quickly.

- Construction: The machinery supports the process of loading cement, sand, gravel, and concrete mixing materials into the mixer at a precise and stable ratio, ensuring the quality of concrete for the project

- Recycling: The devices are an effective solution for recycling plants. Plants that need to load and move recyclable materials such as shredded plastic, crushed glass, or crushed metals into sorting equipment or crushers

For each different field, hopper conveyors provide certain features with effective automated solutions to improve productivity, reduce labor costs, and create uniformity for all output products.

What are the outstanding features of a hopper conveyor?

What are the outstanding features of a hopper conveyor?

Based on the versatile application of hopper conveyors in many fields, some typical features have been proposed that make hopper conveyors stand out from other types of material handling systems:

- Controlled material flow as the conveyor can combine a hopper and a conveyor, allowing for uniform and measured material discharge, reducing the risk of blockages or overflows.

- Versatility in use as whether you are handling fine powders, wet materials or coarse aggregates, hopper conveyors can be customized to suit your specific material type and handling needs.

- Space efficiency with a unique design, the vertical hopper with a compact conveyor system saves valuable floor space while increasing production.

- Automation-ready as hopper conveyors can be integrated into automated lines with sensors, level detectors, and PLC control systems for a fully synchronized production process.

What should you consider when operating a hopper conveyor?

What should you consider when operating a hopper conveyor?

Hopper conveyors have many outstanding features and can be used for a long time. However, to ensure that the equipment operates smoothly and does not wear out over time, you need to pay attention to some basic points below:

- Feeding speed: When using udnjg, technicians should set the appropriate feeding speed to avoid clogging, overflowing or overloading downstream equipment.

- Periodic maintenance: you need to check and clean regularly to avoid accumulation, reduce wear, and prolong the life of the equipment. Pay special attention to bearings, seals, and discharge mechanisms.

- Safety in use: always follow the manufacturer’s instructions. Use shields, emergency stop switches, and locking and tagging systems during maintenance.

- Environmental factors: If you are handling corrosive materials or working in a humid environment, choose conveyors with corrosion-resistant properties and sealed components to ensure operating efficiency as well as equipment life.

How much does a hopper conveyor cost?

How much does a hopper conveyor cost? This is the most common question that every business is concerned about when considering a hopper conveyor. While hopper conveyor systems can have a significant initial cost, they provide long-term value by increasing productivity and reducing material handling time, thereby reducing overall labor costs.

Current market price range:

- Small/light models: $1,500 – $3,500

- Medium models: $4,000 – $8,000

- Heavy-duty models: $8,000 and up

These are just estimates, as the price of each type of conveyor depends on a number of factors, including conveyor length, load capacity, motor power, and the specific material it will handle. But overall, the cost difference is likely not to be too high.

Where is the best place to buy a hopper conveyor?

Where is the best place to buy a hopper conveyor?

There are many reputable conveyor solution providers in Malaysia, but here are 4 reasons why you should prioritize choosing hopper conveyor solutions from DNC Automation:

- Our team of qualified and experienced technicians can recommend the right options for your needs and budget

- We guarantee that our hopper conveyors are 100% genuine, clearly certified, and proven in origin. With fast delivery times, we ensure your production line runs smoothly and efficiently without any delays.

- A dedicated customer care staff system, 24/7 support, and ready to answer all your questions.

- Provide attractive warranty and after-sales policies, a 12-month warranty, and support for repairing damage during use.

If you have any questions, please call the hotline below. We are always happy to help!

- 477 views

- 0 Comment

Recent Comments