Modular Conveyor Systems: Design, Flexibility, Applications & Key Considerations

Modular conveyor systems are increasingly used in modern manufacturing and automation environments where flexibility, scalability, and fast reconfiguration are essential. Built from standardized and interchangeable modules, modular conveyors allow production lines to be easily adapted to changing products, layouts, and throughput requirements.

What is a modular conveyor and how does it differ from traditional conveyors?

A modular conveyor is a conveyor system built from standardized, interchangeable modules that can be assembled, modified, or expanded with minimal structural changes. Instead of being custom-fabricated as a single fixed structure, a modular conveyor is designed as a configurable system.

Key differences between modular conveyors and traditional fixed conveyors include:

- Modular construction philosophy: Modular conveyors are composed of repeatable modules such as straight sections, curves, drive units, and supports. Traditional conveyors are often custom-built as one rigid system, making modifications complex and costly.

- Ease of reconfiguration: Modular systems allow sections to be added, removed, or rearranged as production requirements change, whereas fixed conveyors usually require cutting, welding, or structural redesign.

- Scalability over time: Modular conveyors are designed to grow with the production line, while fixed conveyors are optimized for a single layout and capacity.

How does a modular conveyor system work in practice?

In practical operation, a modular conveyor functions as a flexible material transport platform that can adapt to layout changes without disrupting production.

A typical modular conveyor system works through the following elements:

- Standardized conveyor modules: Straight sections, curves, inclines, and declines are pre-engineered to connect seamlessly, ensuring predictable performance and alignment.

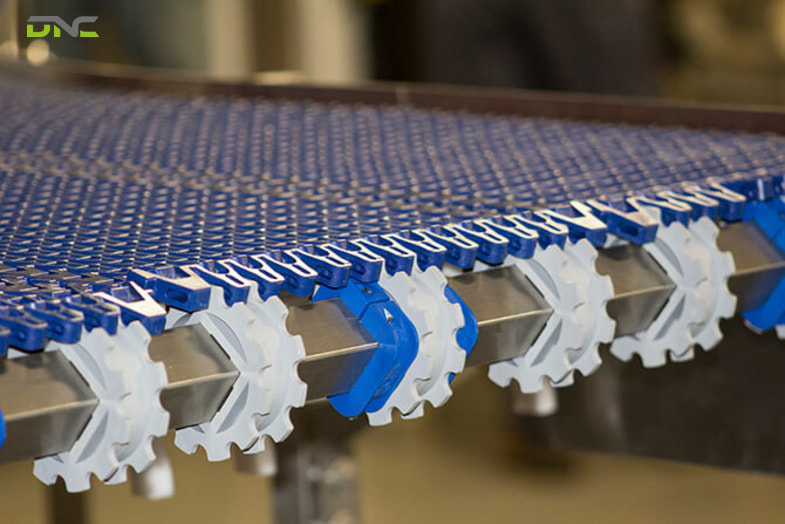

- Modular belt or roller assemblies: Depending on the application, the system uses modular belts, rollers, or chains that can be replaced individually rather than as a whole.

- Drive and return modules: Drive units are integrated into specific modules, allowing power to be applied locally without redesigning the entire system.

- Adjustable supports and frames: Height-adjustable legs and frames allow the conveyor to align with different machines or workstations.

This modular approach enables faster installation, easier maintenance, and rapid adaptation to production changes.

How does a modular conveyor system work in practice?

What types of modular conveyors are commonly used in industry?

Modular conveyors are available in several configurations, each designed for specific material handling needs.

Common types include:

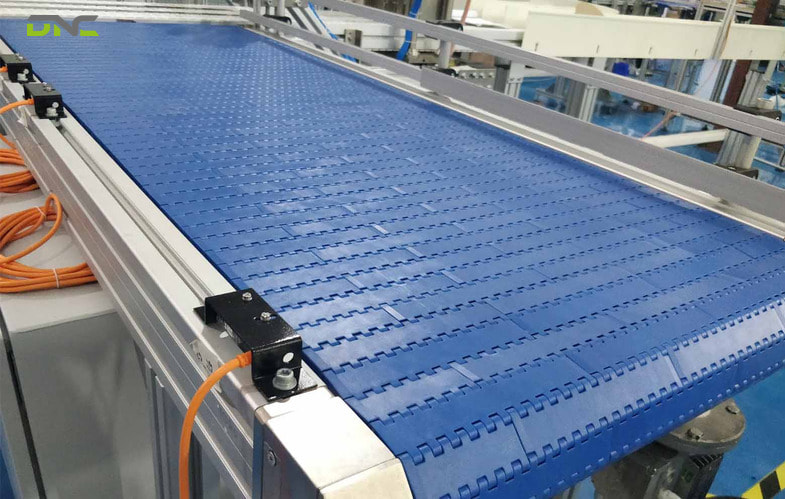

- Modular belt conveyors: Use interlocking plastic or metal belt segments. They are widely used in manufacturing and packaging due to their flexibility, cleanliness, and ease of maintenance.

- Modular roller conveyors: Designed for unit loads such as cartons or totes. Rollers can be gravity-driven or powered and are easy to reconfigure as layouts change.

- Modular chain conveyors: Use chains instead of belts or rollers, making them suitable for heavier products or applications requiring precise product positioning.

- Flexible modular conveyor systems: Designed for highly dynamic environments, these systems can be quickly reconfigured or extended to support temporary or variable workflows.

What materials and products are modular conveyors designed to handle?

Modular conveyors are optimized for unit handling and light-to-medium load applications.

Typical materials and products include:

- Packaged goods and cartons: Boxes, parcels, and shipping units commonly found in manufacturing and distribution centers.

- Containers and bottles: Frequently used in food, beverage, and consumer goods production where product flow changes often.

- Food products: Especially in applications requiring hygienic design and easy cleaning.

- Lightweight industrial components: Parts used in assembly lines where frequent layout changes are required.

- Products with frequent changeovers: Modular conveyors support quick line adjustments for multiple product variants.

Modular conveyors are optimized for unit handling and light-to-medium load applications.

What are the main advantages of using modular conveyors?

Modular conveyors offer several advantages that make them attractive in modern production environments.

Key advantages include:

- High flexibility and adaptability: Systems can be reconfigured quickly to accommodate new products, layouts, or production volumes.

- Reduced installation and modification time: Standardized modules minimize engineering and installation effort compared to custom-built systems.

- Scalability for future expansion: Additional modules can be integrated without major redesign or downtime.

- Simplified maintenance and spare parts management: Individual modules or components can be replaced without dismantling the entire conveyor.

- Support for lean and agile manufacturing: Modular conveyors align well with production systems that emphasize adaptability and continuous improvement.

What limitations should be considered when using modular conveyors?

Despite their flexibility, modular conveyors are not suitable for every application.

Important limitations include:

- Load and capacity constraints: Modular conveyors are generally not designed for extremely heavy or high-impact materials.

- Limited suitability for abrasive bulk materials: Applications involving sand, gravel, or sharp materials may cause excessive wear.

- Higher initial planning requirements: Poor initial module selection can limit future flexibility or performance.

- Potential speed and throughput limitations: Very high-speed or high-capacity applications may require custom-engineered solutions.

Despite their flexibility, modular conveyors are not suitable for every application.

How do modular conveyors support flexible and automated production?

Modular conveyors play a key role in modern automation strategies.

They support automation by:

- Adapting to frequent product changes: Modular layouts can be quickly adjusted for different product sizes or flows.

- Integrating easily with automation equipment: Robots, sensors, sorters, and vision systems can be added without major structural changes.

- Reducing downtime during reconfiguration: Layout changes can often be performed without stopping the entire production line for extended periods.

- Supporting Industry 4.0 initiatives: Modular conveyors facilitate scalable, data-driven, and reconfigurable production environments.

How do modular conveyors compare with fixed or custom conveyor systems?

When compared to other conveyor approaches:

- Modular conveyors vs fixed conveyors: Modular systems prioritize flexibility, while fixed conveyors maximize stability and capacity.

- Modular conveyors vs custom-built systems: Modular conveyors reduce engineering time and complexity, but may not match the performance of fully custom designs in extreme applications.

- Modular conveyors vs mobile conveyors: Modular conveyors focus on layout flexibility within a fixed area, whereas mobile conveyors focus on relocation between sites.

How do modular conveyors compare with fixed or custom conveyor systems?

Why choose DNC Automation for modular conveyor solutions?

DNC Automation designs modular conveyor systems with a strong focus on flexibility, scalability, and system integration. Instead of treating modular conveyors as isolated components, DNC approaches them as part of a complete production and automation workflow.

By understanding real manufacturing constraints—such as frequent layout changes, multiple product variants, and automation integration—DNC Automation helps ensure that modular conveyor systems remain easy to reconfigure, reliable in operation, and adaptable to future expansion.

- 0 views

- 0 Comment

Recent Comments