Motorized Conveyor Rollers for Advanced Automation

Modern production and warehouse operations face constant pressure to move goods faster, reduce downtime, and cut energy consumption without increasing system complexity. Traditional conveyor drives often struggle to keep up with flexible layouts, zoning requirements, and automation integration demands. This is where motorized conveyor rollers provide a smarter solution.

By combining the drive motor directly inside the roller, these systems simplify conveyor design while improving efficiency, control, and reliability. For businesses seeking scalable automation solutions that support high throughput and long-term operational stability, motorized conveyor rollers address both performance challenges and future expansion needs.

What Are Motorized Conveyor Rollers?

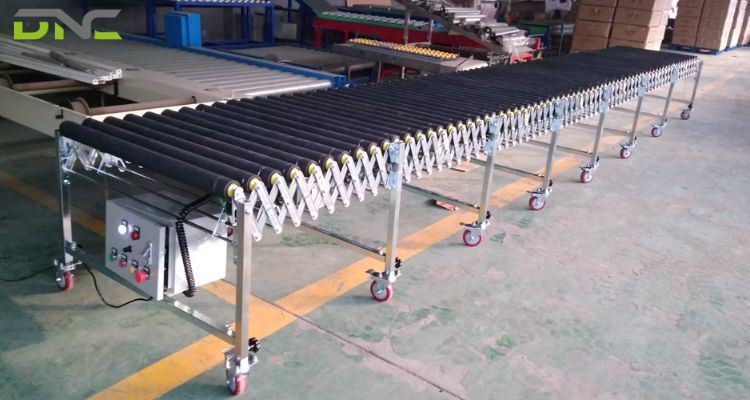

Motorized conveyor rollers are self-contained conveyor components where the electric motor, gearbox, and drive mechanism are integrated directly inside the roller shell. Unlike conventional conveyor systems that rely on external motors, chains, or belts, each roller operates independently or in controlled zones.

This design enables precise product movement, reduced mechanical complexity, and improved energy efficiency. Motorized conveyor rollers are commonly used in automated material handling systems where modularity, quiet operation, and intelligent control are essential. Their compact structure allows seamless integration into modern conveyor layouts without requiring extensive mechanical transmission components.

How Motorized Conveyor Rollers Work

Motorized conveyor rollers operate by embedding a low-voltage motor, typically DC, inside the roller body. Each roller drives products directly, eliminating the need for external power transmission. Understanding how motorized conveyor rollers function helps clarify why they are widely adopted in modern automation systems, particularly where precise control, efficiency, and scalability are critical.

- Integrated motor and gearbox: The motor and gearbox are housed within the roller, allowing direct torque transfer to the conveyor surface. This minimizes energy loss and reduces mechanical wear compared to chain- or belt-driven systems.

- Zone-based control capability: Rollers can be grouped into zones that activate only when products are present. This intelligent control reduces unnecessary motion, improves accumulation handling, and enhances overall system efficiency.

- Low-voltage operation: Most motorized conveyor rollers operate on low-voltage power, improving workplace safety while simplifying electrical integration with PLCs, sensors, and automation controls.

Key Benefits of Motorized Conveyor Rollers

Motorized conveyor rollers deliver multiple operational and technical advantages that support modern automation strategies.

- Energy efficiency: Because rollers activate only when needed, power consumption is significantly reduced. This makes motorized conveyor rollers ideal for facilities focused on sustainable and cost-efficient operations.

- Reduced maintenance requirements: With fewer external moving parts such as chains or belts, maintenance intervals are extended. Integrated designs reduce mechanical stress and improve long-term reliability.

- Compact and modular design: The space-saving structure allows flexible conveyor layouts and easy system expansion. This modularity supports evolving production and logistics requirements without major redesigns.

- Low noise operation: Motorized conveyor rollers operate quietly, improving working conditions and making them suitable for environments where noise control is important.

Common Applications of Motorized Conveyor Rollers

Motorized conveyor rollers are widely used across automated material handling environments due to their adaptability and performance.

- Warehouse and distribution centers: They support carton transport, accumulation, and sorting with precise control, helping optimize order fulfillment and throughput efficiency.

- Manufacturing and assembly lines: In production environments, motorized conveyor rollers ensure consistent product flow between workstations while supporting takt time and automation synchronization.

- Packaging and inspection systems: Accurate speed control allows smooth product handling during labeling, weighing, scanning, and quality inspection processes.

- E-commerce fulfillment systems: High-speed, zone-controlled conveyors powered by motorized rollers are ideal for dynamic order picking and sorting operations.

Motorized Conveyor Rollers vs Traditional Conveyor Drives

Choosing the right conveyor drive technology directly impacts system efficiency, flexibility, and operating costs.

| Comparison Criteria | Motorized Conveyor Rollers | Traditional Conveyor Drives |

|---|---|---|

| Drive mechanism | Motor integrated inside roller | External motor with belts or chains |

| Energy efficiency | High due to zone control | Lower due to continuous operation |

| Maintenance | Minimal moving parts | Regular belt/chain maintenance |

| System flexibility | Highly modular and scalable | Limited flexibility |

| Noise level | Low | Moderate to high |

| Control precision | High, zone-based | Limited |

This comparison highlights why motorized conveyor rollers are increasingly preferred in automated conveyor systems.

How to Select the Right Motorized Conveyor Rollers

Selecting suitable motorized conveyor rollers requires evaluating both operational and system-level factors.

- Load capacity and product characteristics: Roller selection must consider product weight, dimensions, and surface characteristics to ensure reliable traction and smooth movement.

- Conveyor speed requirements: Different applications demand different speeds. Matching roller specifications to throughput requirements ensures optimal performance without overloading components.

- Control system compatibility: Rollers should integrate seamlessly with PLCs, sensors, and warehouse management systems to support automation logic and real-time monitoring.

- Environmental conditions: Factors such as temperature, humidity, and cleanliness requirements influence material selection and sealing options for long-term durability.

Integration with Automation and Control Systems

Motorized conveyor rollers are designed to work seamlessly within automated environments.

- PLC and sensor integration: Each zone can be controlled by sensors and PLC logic, enabling intelligent accumulation, zero-pressure conveying, and product tracking.

- Scalable automation architecture: Modular roller systems allow gradual expansion as operational needs grow, supporting phased automation investments.

- Data-driven optimization: Integration with control systems enables performance monitoring, fault detection, and process optimization to improve overall system efficiency.

Why Are Motorized Conveyor Rollers the Right Choice for Modern Automation?

Motorized conveyor rollers align with the growing demand for flexible, efficient, and intelligent material handling solutions.

- Support for smart factories: Their compatibility with automation controls makes them ideal for Industry 4.0 environments.

- Improved operational efficiency: Reduced downtime, lower energy usage, and simplified maintenance contribute to long-term cost savings.

- Future-ready design: Modular systems adapt easily to layout changes, new processes, and evolving automation requirements.

Why Is DNC Automation a Trusted Partner for Motorized Conveyor Rollers?

Selecting the right automation partner is as important as choosing the right conveyor technology. Why should businesses trust DNC Automation for motorized conveyor rollers?

- Automation-focused system design: DNC Automation engineers motorized conveyor roller systems that align with overall automation strategies, ensuring seamless integration with production and warehouse workflows.

- Customized conveyor solutions: Each system is tailored to specific operational requirements rather than relying on standard configurations, maximizing performance and reliability.

- End-to-end project support: From system design and component selection to installation and optimization, DNC Automation provides comprehensive support throughout the project lifecycle.

- 1 views

- 0 Comment

Recent Comments