PLC Conveyor Systems: Control Logic, Components, Safety & Automation Benefits

PLC conveyor systems are widely used in modern industrial environments where conveyors must operate safely, reliably, and in coordination with other equipment. By using a programmable logic controller, conveyor operation can be precisely controlled through software-defined logic rather than manual or relay-based control.

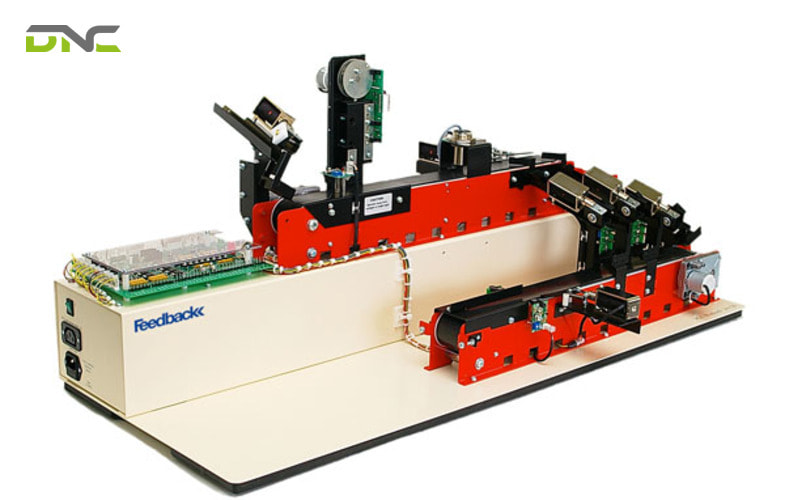

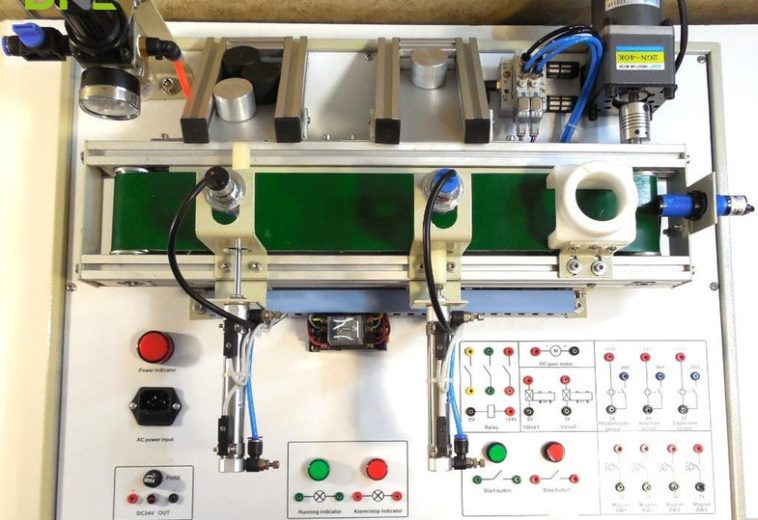

What is a PLC conveyor system?

As conveyor systems grow in size and complexity, manual control or relay-based logic becomes difficult to manage, maintain, and scale. A PLC conveyor system is designed to provide structured, programmable, and centralized control for conveyor operation.

A PLC conveyor system is characterized by:

- Centralized logic control: All conveyor behaviors—start, stop, speed changes, interlocks, and fault responses—are defined in PLC software. This eliminates scattered control logic and makes system behavior predictable and transparent.

- Rule-based and repeatable operation: Conveyors operate according to predefined rules rather than operator judgment. This improves consistency across shifts and reduces dependence on individual operator experience.

- High integration capability: PLC-controlled conveyors can easily exchange signals and data with machines, feeders, sensors, and higher-level systems such as SCADA or MES.

- Scalable system architecture: Additional conveyors, zones, or control functions can be added through program expansion rather than extensive rewiring.

How does a PLC control a conveyor system?

PLC control is based on a continuous scan cycle that allows the system to respond dynamically to real-time conditions.

The control process typically includes:

- Input signal acquisition: The PLC reads signals from photoelectric sensors, proximity sensors, encoders, push buttons, emergency stops, and safety relays. These inputs represent the current physical state of the conveyor and its environment.

- Logic evaluation and decision-making: The PLC evaluates permissives, interlocks, timers, counters, and sequence conditions. For example, a conveyor may only start if downstream conveyors are running and no fault conditions are active.

- Output command execution: Based on the evaluated logic, the PLC sends commands to motors, VFDs, solenoids, and actuators to control movement, speed, and direction.

- Continuous scan and update: This cycle repeats continuously, allowing the PLC to react quickly to jams, product accumulation, or safety events.

PLC control is based on a continuous scan cycle that allows the system to respond dynamically to real-time conditions.

What are the main components of a PLC conveyor system?

A PLC conveyor system consists of multiple components that must operate together reliably.

- PLC controller (CPU and I/O modules): The PLC executes control logic and serves as the communication hub between field devices and control systems.

- Motor and drive systems (VFDs or soft starters): Drives control conveyor speed, torque, acceleration, and deceleration, which are critical for smooth startup and controlled stopping.

- Sensors and feedback devices: Sensors detect product presence, conveyor position, belt speed, and system status, enabling closed-loop and condition-based control.

- Human–Machine Interface (HMI): HMIs provide operators with real-time visibility into conveyor status, alarms, operating modes, and manual control options.

- Electrical panels and communication networks: Panels house control hardware, while industrial networks enable reliable communication between PLCs, drives, and remote I/O.

What types of conveyor control logic are commonly used in PLC systems?

Different conveyor applications require different control strategies.

Common PLC conveyor logic types include:

- Start/stop logic with permissives: Ensures conveyors only run when safety conditions and process requirements are satisfied, reducing the risk of improper operation.

- Sequential control logic: Coordinates the startup and shutdown of multiple conveyors to prevent material buildup, backflow, or mechanical overload.

- Zone-based control logic: Divides conveyors into zones that can stop or run independently, improving material flow control and throughput.

- Accumulation and release logic: Allows products to queue without contact or pressure, protecting product quality in packaging and logistics systems.

- Fault detection and alarm logic: Detects jams, overloads, sensor failures, and abnormal conditions, enabling faster troubleshooting and reduced downtime.

Safety and reliability are major reasons for adopting PLC-controlled conveyors.

How does PLC conveyor control improve safety and reliability?

Safety and reliability are major reasons for adopting PLC-controlled conveyors.

PLC conveyor systems improve safety and reliability by:

- Continuous safety monitoring: Emergency stops, guards, and safety interlocks are continuously monitored rather than checked only during startup.

- Controlled startup and shutdown sequences: Gradual acceleration and deceleration reduce mechanical stress and prevent sudden material movement.

- Automatic fault response: Conveyors can stop automatically or switch to safe states when abnormal conditions are detected.

- Clear diagnostics and alarm messaging: Operators receive clear information about faults, reducing response time and human error.

How does PLC conveyor control support process automation?

PLC-controlled conveyors act as active elements in automated production systems.

They support automation by enabling:

- Process-driven conveyor operation: Conveyor behavior adapts based on upstream and downstream machine status rather than fixed timing.

- Synchronization across equipment: Conveyors coordinate with feeders, robots, weighers, and packaging machines to maintain balanced flow.

- Data exchange with higher-level systems: Production data, alarms, and status information can be shared with SCADA, MES, or ERP systems.

- Flexible operating modes: Systems can switch between automatic, semi-automatic, and manual modes as needed.

What advantages do PLC-controlled conveyors offer compared to conventional control?

PLC-controlled conveyors offer advantages that go beyond simple automation.

Key advantages include:

- Software-based logic modification: Control changes can be implemented without physical rewiring.

- Improved system transparency: Operators and engineers can see exactly why a conveyor is running or stopped.

- Better long-term maintainability: Structured programs and diagnostics simplify troubleshooting and upgrades.

- Higher operational consistency: Reduced variability improves overall process stability.

PLC-controlled conveyors offer advantages that go beyond simple automation.

Why choose DNC Automation for PLC conveyor solutions?

From a system integration perspective, PLC conveyor performance depends on how well logic, hardware, and process requirements are aligned.

DNC Automation focuses on:

- Clear and maintainable PLC logic structures

- Correct selection and placement of sensors and drives

- Stable operation under real industrial conditions

- Scalable designs that support future automation goals

This approach helps ensure PLC conveyor systems remain reliable, safe, and adaptable over time.

- 0 views

- 0 Comment

Recent Comments