How Robotic Palletizers Boost Efficiency, Safety, and ROI in Manufacturing

In modern manufacturing, robotic palletizers are redefining how goods are stacked, packed, and prepared for shipment. By combining robotics, vision systems, and intelligent control software, these systems streamline end-of-line operations with unmatched precision and consistency. From high-speed beverage lines to mixed-load e-commerce logistics, robotic palletizing delivers greater productivity, improved safety, and long-term ROI. For Malaysian factories embracing Industry 4.0, it’s a key step toward full-scale smart factory automation.

What Are Robotic Palletizers and How Do They Work?

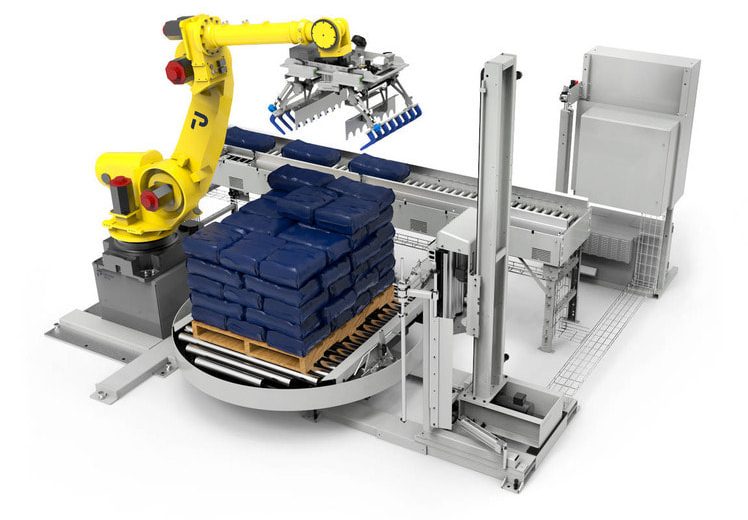

Robotic palletizers are automated systems designed to stack, organize, and transfer products onto pallets efficiently and safely — a vital process at the end of production or packaging lines. Instead of relying on manual labor to lift and arrange boxes, robotic palletizers use programmable robotic arms or gantry systems to perform these repetitive tasks with high precision and speed.

A typical robotic palletizing system consists of several key components:

- Robot Arm: The mechanical unit that performs the lifting and placement motions, equipped with multiple axes for flexibility.

- Gripper or End Effector: Custom-designed tools such as vacuum grippers, clamps, or magnetic heads that handle different product types — from cartons to sacks to bottles.

- Vision System: Cameras and sensors that detect product orientation, position, and quality to ensure accurate stacking patterns.

- Conveyor Feed: Transports products to the robot’s pick-up zone for continuous, automated handling.

Pallet Dispenser: Automatically provides empty pallets to the loading zone, enabling uninterrupted operation. - Safety Enclosure: Ensures operator safety through light curtains, fences, or collaborative modes (in cobot systems).

Robotic palletizers are automated systems designed to stack, organize, and transfer products onto pallets efficiently and safely

What Are the Different Types of Robotic Palletizers?

Modern robotic palletizers come in several configurations, each suited for specific applications, product types, and factory layouts. The table below summarizes the main types, their key features, and common industry use cases:

| Type of Robotic Palletizer | Key Features | Industry Applications |

| Cartesian / Gantry Palletizer | Operates on linear X-Y-Z axes; handles heavy or bulky loads; extremely stable and precise movement. | Ideal for high-speed production lines, building materials, chemicals, and beverages where products are uniform and weighty. |

| Articulated Arm Palletizer | Multi-axis flexibility; compact footprint; handles mixed product sizes; quick reprogramming for SKU changes. | Common in FMCG, food & beverage, logistics, and consumer goods industries requiring flexible palletizing patterns. |

| Collaborative Palletizer (Cobot) | Safe to operate near humans; easy to program; energy-efficient; small space requirement. | Suitable for SMEs, warehouses, or low-to-medium volume lines where safety and adaptability are top priorities. |

| Layer Palletizer | Forms complete layers before stacking; ensures consistent, stable pallet loads; increases throughput. | Used in high-speed, uniform packaging environments such as carton packing, bottling, or bagged goods. |

Modern robotic palletizers come in several configurations, each suited for specific applications, product types, and factory layouts

What Are the Benefits of Using Robotic Palletizers?

Implementing robotic palletizers delivers measurable gains in efficiency, safety, and return on investment across manufacturing and logistics environments. These systems automate repetitive, labor-intensive palletizing tasks, freeing human workers to focus on higher-value operations.

- Increased Throughput and Consistency: Robotic palletizers operate continuously with minimal downtime, maintaining uniform stacking patterns and precise product placement.

- Enhanced Workplace Safety: By eliminating the need for manual lifting, bending, or repetitive movements, robotic palletizers greatly reduce the risk of workplace injuries and fatigue.

- Optimized Use of Space: Compared to traditional mechanical palletizers, robotic systems are more compact and flexible in layout. Their space-efficient cells can be easily reconfigured, allowing manufacturers to maximize floor space and adapt to new production line setups.

- Adaptability and Flexibility: Modern robotic palletizers can be quickly reprogrammed to handle new SKUs, packaging formats, or product dimensions. This adaptability is critical in fast-moving industries where production demands change frequently or where mixed-product pallets are required for distribution.

- Long-Term Cost Efficiency: Although initial setup costs may be higher, robotic palletizers reduce labor expenses, minimize downtime, and extend system lifespan through predictive maintenance. The result is a strong productivity improvement and lower total cost of ownership (TCO) over time.

Benefits of Using Robotic Palletizers

Key Components and Technologies Behind Robotic Palletizing Systems

Behind every efficient robotic palletizer is a combination of advanced hardware, sensors, and intelligent software that ensure smooth, reliable, and precise operation. Understanding these technologies helps businesses assess system capability and integration potential in a smart factory environment.

- Vision Systems and AI Algorithms: Integrated robotic vision systems use cameras and machine learning to detect product orientation, dimensions, and position in real time. AI-driven algorithms enable adaptive stacking patterns, improving accuracy and speed even when product alignment varies on the conveyor.

- Grippers and End Effectors: The end effector is the robot’s working tool, responsible for picking and placing items. Options include vacuum grippers for cartons or bags, mechanical clamps for heavy items, and magnetic grippers for metal parts.

- Sensors and Load Cells: Smart sensors and load cells continuously monitor product weight, alignment, and pallet stability. These components provide feedback for precise placement and automated layer correction.

- Software and PLC/HMI Integration: The robotic palletizer interfaces with plant control systems through PLC automation and HMI panels, coordinating with conveyors, AGVs, and upstream packaging equipment. This integration enables synchronized operation, seamless line control, and easier diagnostics.

- Data Connectivity and System Integration: Modern palletizers connect to Warehouse Management Systems (WMS), Warehouse Control Systems (WCS), or Manufacturing Execution Systems (MES) for real-time visibility.

Challenges and Considerations Before Implementing Robotic Palletizers

While robotic palletizers offer strong ROI and operational benefits, their success depends on careful planning, integration, and long-term support. Below are key challenges and considerations that companies should evaluate before deployment:

- Initial Investment and Cost Justification: The upfront cost of robotic systems — including hardware, integration, and safety enclosures — can be significant. Businesses should conduct a thorough ROI in automation analysis, factoring in labor savings, reduced downtime, and throughput improvements.

- Integration with Existing Systems: Robotic palletizers must align with legacy conveyors, ERP/WMS systems, and production equipment. Proper system integration ensures seamless product flow, real-time inventory tracking, and accurate order fulfillment.

- Factory Layout and Space Constraints: Designing an optimal factory layout is crucial. Cell dimensions, pallet infeed/outfeed zones, and safety fences must be considered to maintain efficient material flow while meeting safety regulations.

- Operator Training and Safety Compliance: Operators and maintenance teams must receive proper training on robot programming, troubleshooting, and emergency response. All installations should comply with safety certification standards (e.g., ISO 10218, CE, or Malaysia DOSH guidelines).

- Local Maintenance and Technical Support: A reliable partner with local engineering capability ensures timely support, spare parts availability, and on-site troubleshooting — all critical for minimizing downtime and maximizing system lifespan.

Challenges and Considerations Before Implementing Robotic Palletizers

Why Choose DNC Automation for Robotic Palletizer Solutions?

As one of Malaysia’s leading industrial robotics integrators, DNC Automation has a proven track record in designing and implementing end-of-line packaging automation tailored to each client’s production environment.

- Over 10 Years of Automation Expertise: DNC brings a decade of experience in factory automation, robotics integration, and motion control systems, serving clients across food, pharmaceutical, logistics, and manufacturing sectors.

- Customized End-of-Line Solutions: From robotic palletizing to case packing and labeling, DNC designs fully integrated automation systems that streamline production and improve overall equipment efficiency (OEE).

- Seamless Integration with Connected Systems: DNC’s solutions can integrate with AGVs, conveyors, vision inspection systems, and WMS platforms for synchronized, data-driven logistics operations.

- Local Engineering, Support, and Training: With an in-house team of Malaysian engineers, DNC provides responsive maintenance, spare part support, and comprehensive operator training — ensuring long-term system reliability and customer satisfaction.

FAQ: Robotic Palletizers

1. What’s the difference between a robotic palletizer and a conventional one?

Traditional palletizers rely on fixed mechanical movements, while robotic palletizers use programmable robotic arms capable of handling multiple product types and stacking patterns. This provides greater flexibility and space efficiency.

2. Can robotic palletizers handle mixed-product or random-size loads?

Yes. With advanced vision systems and adaptive grippers, robotic palletizers can manage mixed-case palletizing, ideal for e-commerce or consumer goods distribution.

3. How long does installation and setup take?

Implementation time varies by project complexity but typically ranges from 4 to 10 weeks, including layout design, robot programming, safety testing, and operator training.

4. What’s the typical ROI period?

Most companies achieve ROI within 1 to 3 years, depending on labor savings, system uptime, and production volume increases.

5. Can DNC customize a palletizer for my industry or space constraints?

Absolutely. DNC specializes in custom robotic palletizer design, adapting configurations to your factory layout, payload type, and throughput requirements.

- 6 views

- 0 Comment

Recent Comments