Scraper Chain Conveyor: Benefits, Types & Applications

In industrial automation, choosing the right conveyor system is crucial for enhancing productivity and operational efficiency. Scraper chain conveyors are a key solution for industries dealing with heavy or abrasive materials that need to be transported efficiently. However, choosing the right scraper chain conveyor can be overwhelming with the variety of systems available.

Understanding their benefits, types, and applications can help you make informed decisions. In this article, we will dive deep into scraper chain conveyors, their features, and how they can optimize your automation processes.

What is a Scraper Chain Conveyor?

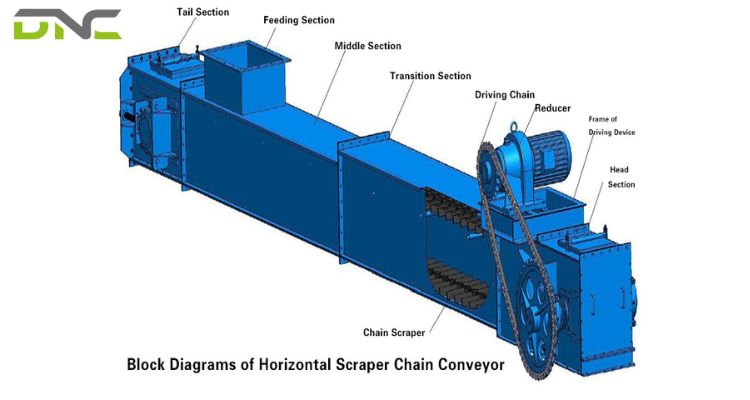

A scraper chain conveyor is a type of conveyor system that uses a chain with attached scrapers to move materials through an enclosed track. It is commonly used in industries where bulk materials like sludge, scrap, or coal need to be transported across long distances. The scraper chain works by pulling the material along a track, making it ideal for handling heavy, abrasive, or sticky materials that might otherwise clog or damage other conveyor types.

What Are the Benefits of Scraper Chain Conveyors?

Scraper chain conveyors offer several advantages in terms of efficiency, durability, and ease of maintenance. Here’s a breakdown of why they are widely used in industries:

- Durability and Longevity: Scraper chain conveyors are built to handle harsh environments and heavy loads, making them incredibly durable. They are designed to withstand abrasive materials and extreme temperatures, ensuring a long lifespan.

- Efficient Material Handling: Unlike other conveyor types, scraper chain conveyors can move dense and sticky materials without clogging, improving overall material flow and productivity.

- Low Maintenance Costs: These systems require relatively low maintenance. With proper care and regular inspections, their operational costs can be minimized, ensuring more uptime and less repair work.

- Versatility in Applications: Scraper chain conveyors are highly versatile. They can be customized to suit various industries such as food processing, mining, agriculture, and manufacturing, transporting materials such as coal, food scraps, and waste.

- Space Efficiency: These conveyors can be installed in tight spaces due to their compact design, making them ideal for facilities with limited room for larger conveyor systems.

Types of Scraper Chain Conveyors

Scraper chain conveyors come in several variations, each suited to specific tasks and material types. Understanding the different types can help you select the best option for your application.

1. Enclosed Track Scraper Conveyors

- Ideal for transporting heavy and abrasive materials.

- Commonly used in industries like mining, cement production, and waste management.

2. Open Track Scraper Conveyors

- Best for lighter materials.

- Often used in food processing, packaging, and other industries requiring less rugged conveyor systems.

3. Slat Chain Scraper Conveyors

- Typically used in environments where temperatures are extremely high.

- Common in industries like foundries and metalworking.

4. Heavy-Duty Scraper Chain Conveyors

- Designed for extremely heavy materials such as scrap metal or raw ores.

- Suitable for high-load applications where other conveyors may fail.

Scraper Chain Conveyor vs. Other Conveyor Systems

When considering different types of conveyors, understanding how scraper chain conveyors compare to other systems is essential. Here’s a quick comparison:

| Feature | Scraper Chain Conveyor | Belt Conveyor | Roller Conveyor | Bucket Elevator |

| Material Type | Heavy, abrasive, sticky | Lightweight | Heavy materials | Bulk materials |

| Durability | High | Medium | Medium | High |

| Maintenance | Low | Medium | High | Medium |

| Energy Efficiency | Medium | High | Medium | Low |

| Cost | Medium | Low | Medium | High |

| Space Efficiency | High | Medium | Low | High |

How Does a Scraper Chain Conveyor Fit Into Automated Systems?

In modern automation, scraper chain conveyors play a crucial role in streamlining production and material handling processes. These systems seamlessly integrate with automated lines to ensure continuous material flow and reduce human labor. Here’s how scraper chain conveyors contribute to automation:

- Integration with Control Systems: Scraper chain conveyors can be easily integrated with advanced control systems that monitor speed, load, and material flow. This ensures optimal performance and reduces the risk of downtime.

- Real-Time Monitoring: Automation technologies allow for real-time monitoring of the conveyor system, providing alerts for maintenance or potential breakdowns. This helps in predictive maintenance and reduces unexpected failures.

- Customization: Scraper chain conveyors can be tailored to fit the unique needs of your facility. Whether it’s the length of the conveyor, the speed of operation, or the material type, automation solutions can be adjusted to optimize performance.

Why Choose DNC Automation for Scraper Chain Conveyor Systems?

When choosing a conveyor system, it’s essential to partner with a trusted provider that can design, install, and maintain efficient solutions tailored to your business’s needs. DNC Automation is a leader in industrial automation and material handling solutions, offering expert guidance on choosing the right scraper chain conveyor for your specific application.

- Expertise in Automation Solutions: With years of experience, we design automation systems that fit your specific operational requirements.

- Customization: We provide bespoke solutions, ensuring that your scraper chain conveyor is optimized for efficiency and longevity.

- Reliable Service: Our team of professionals ensures that your system is installed and maintained with the utmost care, minimizing downtime.

Contact us now to learn more about how our scraper chain conveyor systems can enhance your material handling and production efficiency. Let us help you streamline your processes with cutting-edge technology!

- 0 views

- 0 Comment

Recent Comments