Warehouse Control System (WCS) – The Brain of Smart Warehouse Operations

Modern automated warehouses deploy sophisticated equipment—conveyors, sortation systems, AS/RS, AGVs, and robotic pickers—creating complex material flow networks. While Warehouse Management Systems (WMS) determine what needs to move, Warehouse Control Systems (WCS) orchestrate how equipment physically executes these movements in real-time.

What Exactly Is a Warehouse Control System (WCS)?

A Warehouse Control System (WCS) is specialized software that manages and optimizes automated material handling equipment in real-time.

Acting as the intermediate intelligence layer between business management systems (WMS, ERP) and physical equipment (conveyors, robots, sorters), WCS translates high-level business instructions into specific equipment commands while continuously monitoring performance and adapting to changing conditions.

How Does a Warehouse Control System Work?

WCS operates through continuous cycles of receiving instructions, optimizing execution plans, directing equipment, monitoring performance, and adapting to real-time conditions.

Step 1: Equipment Control and Coordination

WCS maintains direct communication with all automated equipment via industrial protocols (Profibus, Ethernet/IP, OPC UA). For conveyor systems, WCS controls motor speeds, diverter positions, and accumulation zones—speeding up or slowing sections to prevent jams or gaps.

Step 2: Receiving and Interpreting WMS Instructions

When WMS generates fulfillment requirements—”retrieve these 50 SKUs for Order Batch 147″—WCS receives high-level instructions and decomposes them into granular equipment tasks. The system evaluates current facility state: which equipment is available, where queues exist, what priorities apply, equipment performance status.

Step 3: Real-time Flow Planning and Execution

WCS continuously recalculates optimal material routing as conditions change. If a conveyor section fails, WCS instantly reroutes materials via alternative paths. If one picking station develops queue backlogs, WCS redirects incoming materials to less congested stations. If priority orders arrive, WCS reprioritizes task sequences ensuring urgent items move first.

Step 4: Performance Monitoring and Feedback

Equipment constantly reports status to WCS: current positions, task completions, error conditions, performance metrics. WCS aggregates this data providing real-time visibility through dashboards showing throughput rates, equipment utilization, queue depths, and exception alerts.

Warehouse Control System operates in 4 main steps

What Are the Key Components of a WCS?

A WCS is the essential software layer that manages and directs all automated activities on the warehouse floor. Its core components ensure seamless coordination between planning and physical execution.

- Equipment Control Module: This foundational layer is responsible for the real-time control of all physical automation equipment. It uses drivers and communication protocols to manage the precise movements of conveyors, sorters, AS/RS, and AMRs.

- Order Routing and Sequencing Engine: This is the WCS’s intelligence, dedicated to optimizing material flow and task execution. Its algorithms determine the most efficient path and order for picking, considering task priority, equipment availability, and workload. This minimizes travel time and maximizes system throughput.

- Real-time Monitoring and Data Collection: This component ensures comprehensive operational visibility. It continuously collects sensor data to track equipment status (running/idle/faulted), the precise location of materials, and key performance metrics.

- Interface and Integration Module: This layer is the connectivity hub, linking the WCS with the broader enterprise ecosystem. It uses standardized APIs to integrate with the WMS (for task retrieval) and the ERP system.

- Analytics and Reporting Engine: This final component transforms raw data into actionable intelligence. It generates real-time dashboards and exception reports to quickly highlight bottlenecks and underperformance.

Its core components ensure seamless coordination between planning and physical execution.

What Are the Main Benefits of Using a Warehouse Control System?

A Warehouse Control System (WCS) is the vital link between a WMS and the physical automation on the floor. It acts as the conductor, ensuring all machinery works harmoniously in real-time. Now explore the 5 primary benefits that implementing a WCS delivers to automated warehouses.

- Optimized Material Flow: WCS eliminates congestion and bottlenecks through intelligent routing. Systems dynamically balance loads across equipment preventing overutilization while maximizing throughput.

- Increased Operational Efficiency and Reduced Errors: Automated equipment control eliminates manual intervention reducing human errors in equipment operation. Optimized task sequencing minimizes wasted motion and empty travel.

- Enhanced Monitoring and Proactive Maintenance: Real-time equipment monitoring detects performance degradation before failures. Predictive maintenance alerts schedule repairs during planned downtime rather than reacting to unexpected breakdowns.

- Real-time Data Integration and Inventory Accuracy: Automated data capture eliminates manual tracking errors. Every material movement updates inventory systems instantly providing accurate stock visibility. Lot tracking and traceability occur automatically supporting quality compliance.

- Improved ROI on Automation Investments: WCS maximizes returns from expensive automation equipment by optimizing utilization and performance. Equipment operates at designed capacity rather than sitting idle from poor coordination. Systems adapt to volume fluctuations maintaining productivity.

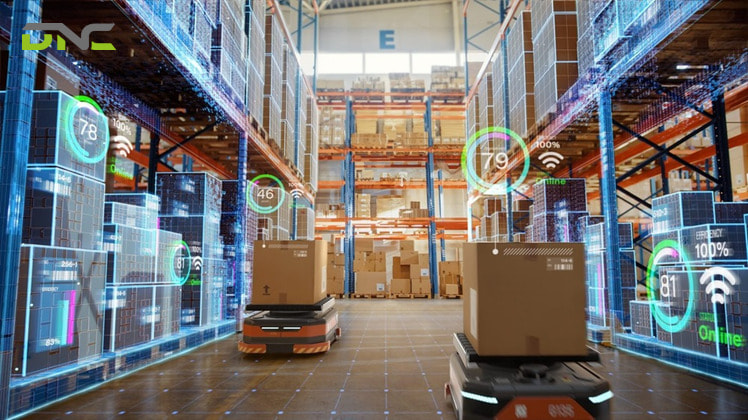

5 primary benefits that implementing a WCS delivers to automated warehouses

What’s the Difference Between WMS and WCS?

In a highly automated environment, the Warehouse Management System (WMS) and the Warehouse Control System (WCS) fulfill distinct but interdependent functions. The WMS operates at the strategic and planning level, focusing on what inventory to process and where to store it. Conversely, the WCS operates at the real-time execution level, focusing on how to physically control and optimize the flow of automated equipment.

| Feature | WMS (Warehouse Management System) | WCS (Warehouse Control System) |

| Primary Purpose | Manage inventory, orders, storage strategies | Control and optimize material handling equipment |

| Operational Level | Business logic and planning layer | Equipment execution and control layer |

| Decision Scope | What to move, where to store, how to pick | How equipment moves items, routing paths, timing |

| Time Horizon | Minutes to hours (order waves, replenishment) | Seconds to minutes (real-time equipment control) |

| Key Functions | Receiving, putaway, inventory tracking, order management, shipping | Equipment coordination, traffic management, task optimization, performance monitoring |

| Typical Users | Warehouse managers, inventory planners, supervisors | Operations engineers, maintenance teams, automation specialists |

| Data Focus | Inventory accuracy, order status, labor productivity | Equipment utilization, throughput rates, system performance |

| Example Tasks | Generate pick list for 100 orders | Route totes through conveyors to correct picking stations |

Difference Between WMS and WCS

What Challenges Can Occur Without a Proper WCS?

Relying only on a WMS to run complex automation equipment is inefficient. Without a dedicated Warehouse Control System (WCS) acting as the real-time conductor, automated systems cannot work harmoniously. 4 key challenges listed below highlight the operational risks inherent when a dedicated WCS layer is absent.

- Poor System Synchronization: Without WCS coordination, equipment operates independently creating inefficiencies. Conveyors run at mismatched speeds causing jams or gaps. Robots complete retrievals but wait for occupied picking stations. Sorters accumulate backlogs from downstream bottlenecks.

- Reduced Productivity and Flow Bottlenecks: Uncoordinated equipment creates congestion points where material accumulates while other areas remain underutilized. Operators manually intervene routing materials or clearing jams—reducing throughput and increasing labor requirements.

- Limited Visibility and Reactive Maintenance: Without WCS monitoring, equipment problems go undetected until failures occur. Maintenance operates reactively rather than proactively. Performance degradation happens gradually unnoticed until severe.

- Inability to Scale Operations: As businesses grow adding equipment or expanding facilities, uncoordinated systems become increasingly complex to manage manually. Each new piece of equipment creates additional coordination challenges.

4 key challenges listed below highlight the operational risks inherent when a dedicated WCS layer is absent

Frequently Asked Questions About WCS

1. Can WCS control equipment from different vendors?

Yes, modern WCS platforms support multi-vendor environments through standardized industrial protocols and flexible integration capabilities. Systems communicate with conveyors from one supplier, sorters from another, and robots from a third vendor.

This vendor-neutral approach allows businesses to select best-in-class equipment for each function rather than being locked into single-vendor solutions. DNC’s WCS implementations regularly integrate equipment from 3-5 different manufacturers creating cohesive systems from diverse components.

2. How long does WCS deployment take?

Implementation timelines depend on facility complexity and existing automation: basic WCS for simple conveyor systems deploys in 6-12 weeks, moderate complexity facilities with multiple equipment types require 3-5 months, and large-scale implementations with extensive automation take 6-12 months including design, configuration, integration, testing, and commissioning.

3. Is WCS suitable for small or medium-sized warehouses?

Absolutely. While historically associated with large automated facilities, modern cloud-based WCS platforms serve operations of all sizes. Small warehouses with basic conveyor systems benefit from optimization and monitoring capabilities.

The decision depends more on automation level than facility size—any operation with multiple automated equipment types benefits from WCS coordination. Cloud-based subscription models make WCS financially accessible to Malaysian SMEs without massive upfront software investments.

Conclusion

A well-designed Warehouse Control System (WCS) is the key to ensuring seamless, efficient, and data-driven warehouse operations. By connecting and controlling every piece of automation equipment — from conveyors, AS/RS, to robotic systems — WCS allows your warehouse to operate with precision, speed, and real-time visibility.

At DNC Automation, we go beyond just supplying technology. With over 10 years of experience in warehouse automation and material handling, our team delivers custom-engineered WCS solutions that perfectly fit your operational flow and business goals.

Whether you are upgrading an existing system or building a smart warehouse from the ground up, DNC provides end-to-end integration, reliable local support, and scalable designs that grow with your business.

- 10 views

- 0 Comment

Recent Comments