What is a Warehouse Management System (WMS)? Overview and Benefits for Businesses

Warehouse management system (WMS) is software that helps businesses control and optimize the entire warehouse process from import – export, storage to transportation. This article by DNC Automation will introduce popular types of WMS, benefits of use and instructions for choosing the right system for each business model.

What are warehouse management systems?

Warehouse Management Systems (WMS) is a specialized software that helps businesses manage, coordinate and optimize all warehouse activities – from receiving goods, storing, controlling inventory to processing orders and shipping.

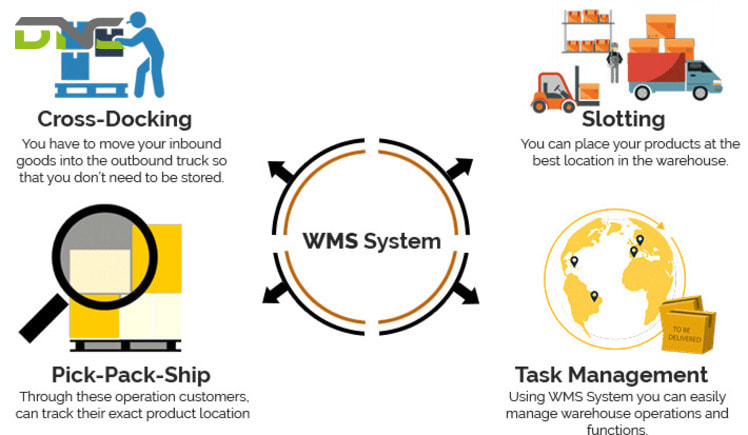

The scope of WMS activities includes:

- Recording and processing data when goods are imported into the warehouse.

- Locating goods in different storage locations.

- Tracking inventory status, expiry date or warning of shortages.

- Optimize the picking, packing and shipping process.

- Integrate with other systems such as ERP, TMS to create a tightly linked supply chain.

What are warehouse management systems?

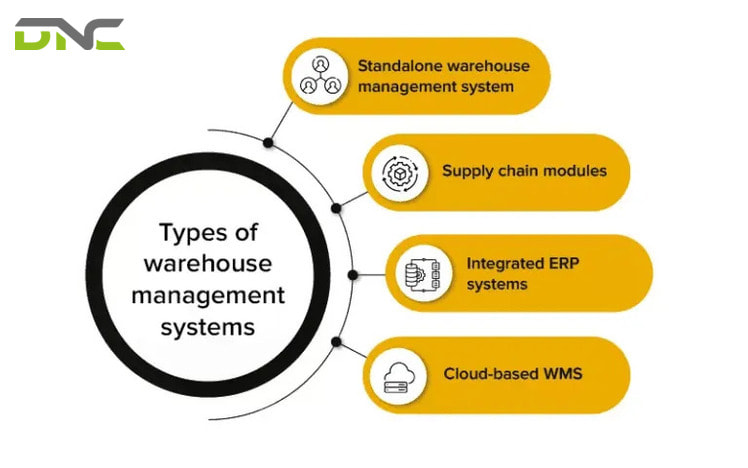

What are the 4 Types of Warehouse Management Systems

In the current market, WMS systems are developed with many different deployment forms to serve the diverse needs of businesses. Below are the 4 most popular types of WMS systems:

Standalone WMS

This is a type of WMS deployed as a separate software, not attached or integrated with other systems such as ERP or CRM.

- This system focuses on core warehouse functions such as: import – export management, inventory control, goods arrangement, storage location management, counting…

- Usually installed internally at the enterprise (on-premise), giving the enterprise full control over management and operation.

Suitable for small or medium-sized enterprises that want to focus on solving warehouse problems without needing a comprehensive management system.

Cloud-based WMS

Cloud-based WMS is a modern model that allows businesses to access and operate the system via the internet. Data is stored and processed on the software provider’s cloud server.

- Users can log in to the system from anywhere, using a computer or mobile device.

- The provider is responsible for maintaining, updating features and securing data.

- Allows for quick and flexible deployment when the business has many warehouses in many locations.

Suitable for businesses that are expanding, need to monitor warehouses remotely, or want to reduce IT infrastructure investment costs.

ERP Module-Based WMS

This is a model in which WMS is developed as part of the ERP (Enterprise Resource Planning) system. WMS then not only supports the warehouse, but also seamlessly connects data with other departments such as: Purchasing, production, sales, etc.

Supply Chain Module-Based WMS

Unlike ERP-based WMS which only focuses internally, this type is part of the overall supply chain management system (Supply Chain Management – SCM). It allows businesses to:

- Connect warehouse data with supply chain partners (suppliers, distribution centers, customers…)

- Analyze and optimize real-time goods flow

- Forecast demand and automatically reorder

4 most popular types of WMS systems

Why should we use WMS system in factories?

Regardless of the form of implementation, WMS systems all aim at the same goal: helping businesses manage their warehouses more effectively. So specifically, what benefits does WMS bring?

- Increasing warehouse management efficiency: Instead of manual recording that is prone to errors, the system supports automatic management from the time of goods receipt, storage, to the time of warehouse delivery.

- Saving time and operating costs: By automating processes such as data entry, inventory, goods positioning, order processing, etc., WMS helps businesses reduce manual workload, thereby saving labor, reducing operating costs and limiting errors.

- High accuracy: This accuracy not only ensures quick inventory but also helps businesses avoid the risk of defective goods, expired goods or mistakes in delivery, thereby increasing reputation with customers.

- Improve decision-making ability: Managers can easily analyze inventory status, identify fast-selling and slow-selling items and make decisions to import goods or adjust sales policies appropriately.

- Flexible expansion as the business grows: Many WMS systems support expansion according to needs such as adding warehouses, new features or integrating with other software.

Advantages of warehouse management systems (WMS)

How to choose the right WMS system for your business?

Choosing the right warehouse management system (WMS) not only helps businesses optimize operational performance but also saves costs and improves competitiveness. Below are important criteria to consider when choosing a WMS system:

- Determine business needs: Businesses need to clearly understand how many warehouses they are managing, the quantity of goods, import – export frequency and operating goals to choose a WMS with suitable functions, avoiding waste.

- Ability to integrate with other systems: WMS should easily connect with software such as ERP, accounting, sales to synchronize data, reduce manual operations and increase operational efficiency.

- Good security and technical support: The system needs to ensure data security, clear authorization and have a technical team ready to support when problems arise.

- Reasonable cost, effective investment: Consider the cost of implementation, maintenance and efficiency to ensure that WMS is truly a worthwhile investment.

- Easy-to-use interface: A friendly, easy-to-use system helps warehouse staff quickly get acquainted, reduces errors and saves training time.

This is important criteria to consider when choosing a WMS system

When should a business deploy a WMS system?

Enterprises should consider implementing a WMS system when the quantity of goods is increasing, the import-export process is complicated and manual warehouse management begins to have many errors.

In addition, if the enterprise expands its scale, operates multiple warehouses at the same time or wants to improve efficiency and reduce operating costs, this is the right time to apply WMS.

In which industries are WMS systems commonly used?

WMS systems are commonly used in many industries with complex logistics operations and strict inventory control requirements. Some typical industries include:

- Retail and e-commerce: WMS helps manage thousands of product codes, process orders quickly and accurately, especially important in the omnichannel model.

- Logistics and supply chain: Logistics companies use WMS to track goods in multiple warehouses, support on-time delivery and increase distribution efficiency.

- Pharmaceuticals and healthcare: WMS helps manage product expiration dates, storage conditions and traceability, meeting strict safety requirements.

- Automotive and components: WMS helps manage thousands of components in detail, ensuring the correct type, quantity and supporting accurate inventory in production according to orders.

- Food and beverage: The system supports temperature control, expiry date and inventory rotation according to FIFO/LIFO principle, ensuring product quality.

Where to buy reputable warehouse management systems?

If you are uncertain about where to purchase a warehouse management systems, DNC Automation is an excellent option for you. Many customers have trusted DNC to provide automation solutions in the production process and have had positive experiences because:

- DNC is a leading technology, automation, and engineering company in Malaysia with over 15 years of experience in the field of automation

- System integration machinery, Internet of Things (IoT), Industry 4.0, and WinCC Scada System

- Diverse designs and sizes are suitable for many domestic and foreign houses. The equipment is 100% genuine and imported from Malaysia.

Please contact us via the hotline below if you have any questions about the product, we are happy to answer you!

- 6 views

- 0 Comment

Recent Comments