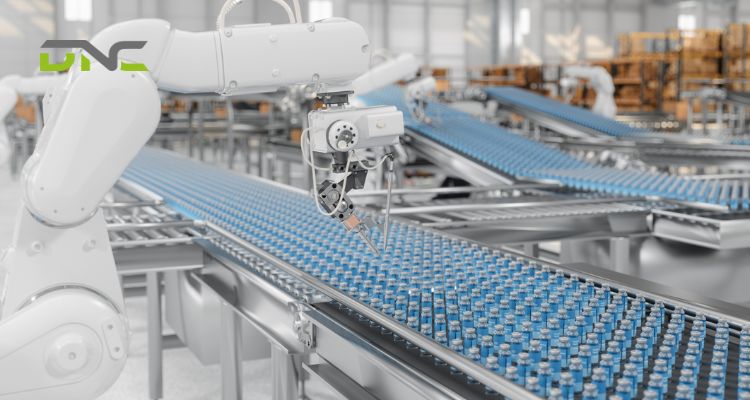

Industrial Conveyor Belt Manufacturer for Automation Systems

Choosing the right industrial conveyor belt manufacturer is a major challenge for many factories and automation projects. Poor-quality belts, weak engineering support, and non-customized designs often lead to downtime, inefficiency, and costly rework. A reliable manufacturer must deliver more than belts—they must provide engineered solutions that integrate seamlessly into automated operations.

What Is an Industrial Conveyor Belt Manufacturer?

An industrial conveyor belt manufacturer specializes in designing, engineering, and producing conveyor belt systems for material handling in industrial environments. Unlike generic suppliers, manufacturers focus on durability, load performance, automation compatibility, and application-specific requirements. Their role extends beyond production to include system design, customization, testing, and long-term operational reliability.

A professional manufacturer understands how conveyor belts interact with motors, drives, sensors, and control systems, ensuring smooth material flow within automated production lines, warehouses, and processing facilities while meeting safety and quality standards.

Key Responsibilities of an Industrial Conveyor Belt Manufacturer

A professional manufacturer plays a critical role throughout the entire lifecycle of a conveyor system, from concept to long-term operation.

Engineering-Based System Design

Manufacturers evaluate load capacity, belt speed, operating environment, and workflow layout before proposing a solution. This engineering-first approach ensures the conveyor belt supports productivity goals and integrates seamlessly with automation systems.

Precision Manufacturing and Assembly

High-quality manufacturers control fabrication processes, material selection, and assembly accuracy. Precision manufacturing ensures belt alignment, consistent tracking, and long service life under continuous industrial use.

Customization for Industrial Applications

Instead of one-size-fits-all products, manufacturers tailor conveyor belts to specific materials, weights, temperatures, and operational demands. Customization improves efficiency and reduces mechanical stress.

Types of Industrial Conveyor Belts Commonly Manufactured

Different industrial operations require conveyor belt systems designed to handle specific materials, loads, and environments. A reliable industrial conveyor belt manufacturer offers multiple belt types to support efficient material flow while maintaining durability and automation compatibility.

- Flat Belt Conveyors: Flat belt conveyors are commonly used for transporting packaged products, cartons, and components along straight or slightly inclined paths. Manufacturers carefully select belt materials and surface finishes to ensure stable movement, low friction, and minimal product damage, making them ideal for assembly and packaging lines.

- Modular Belt Conveyors: Modular conveyor belts consist of interlocking plastic segments that provide flexibility and easy maintenance. These belts are well-suited for applications requiring frequent cleaning, directional changes, or washdown environments, offering long service life and operational reliability.

- Heavy-Duty Conveyor Belts: Heavy-duty conveyor belts are engineered for bulk materials and high-load applications. Reinforced constructions allow them to withstand abrasion, impact, and continuous operation in demanding industrial conditions.

Industries That Rely on Industrial Conveyor Belt Manufacturers

Industrial conveyor belt manufacturers support a wide range of industries that depend on consistent, efficient material handling. Properly designed conveyor systems improve productivity, reduce manual labor, and enhance operational control across various industrial sectors.

- Manufacturing and Assembly Lines: Conveyor belts enable continuous product movement between workstations, reducing bottlenecks and manual handling. Well-engineered systems help maintain consistent production flow and improve overall line efficiency.

- Warehousing and Logistics: In logistics and distribution environments, conveyor belts streamline sorting, loading, and order fulfillment processes. Manufacturers design systems that maximize space utilization while maintaining high throughput and accuracy.

- Processing and Packaging Industries: Processing industries require conveyor belts that meet hygiene, temperature, and safety requirements. Manufacturers ensure belts are designed to handle sensitive materials while maintaining compliance and operational efficiency.

The Importance of Custom Conveyor Belt Manufacturing

Every automation project has unique operational challenges, making custom conveyor belt manufacturing essential for long-term performance and system efficiency. Tailored designs ensure conveyors align with both material characteristics and automation requirements.

- Matching Belt Design to Material Properties: Different materials vary in weight, size, and surface texture. Custom belt designs help prevent slippage, spillage, and product damage, ensuring smooth and controlled material transport.

- Adapting to Facility Layout Constraints: Manufacturers customize conveyor layouts to accommodate space limitations, elevation changes, and complex workflows. This approach improves efficiency without requiring major structural modifications.

- Supporting Automation and Control Integration: Custom conveyor belts are designed to integrate seamlessly with sensors, PLCs, and variable speed drives, enabling precise control and synchronized automation processes.

Quality Standards and Manufacturing Compliance

Quality and safety are critical considerations in industrial conveyor belt manufacturing. A reputable manufacturer follows strict standards to ensure reliable performance, durability, and safe operation throughout the system’s lifecycle.

- Use of Industrial-Grade Materials: Manufacturers select belt materials based on operating conditions such as load, temperature, and environmental exposure. High-quality materials directly contribute to system durability and reduced maintenance.

- Adherence to Safety and Engineering Standards: Conveyor systems are designed in accordance with recognized engineering and safety guidelines. Proper guarding, structural integrity, and operational safety are key priorities.

- Testing and Quality Control Procedures: Before delivery, conveyor belts undergo rigorous testing to confirm load capacity, tracking stability, and reliable performance under real operating conditions.

How to Choose the Right Industrial Conveyor Belt Manufacturer

Selecting the right industrial conveyor belt manufacturer directly affects system reliability, operating costs, and long-term performance. Careful evaluation helps ensure a successful automation investment.

- Evaluate Engineering Expertise: A qualified manufacturer demonstrates strong technical knowledge and application experience. They focus on engineered solutions rather than offering generic conveyor products.

- Assess Customization Capability: Manufacturers should provide flexible design options that address specific operational requirements. Custom solutions deliver better performance than standard catalog systems.

- Consider After-Sales Support: Reliable technical support, spare parts availability, and maintenance guidance are essential for minimizing downtime and maintaining system efficiency over time.

Why Is DNC Automation a Trusted Industrial Conveyor Belt Manufacturer?

Choosing the right partner is essential when investing in an industrial conveyor system. Why is DNC Automation considered a trusted industrial conveyor belt manufacturer for automation-driven projects?

- Automation-Focused Engineering Design: DNC Automation designs conveyor belt systems with automation integration in mind, ensuring compatibility with control systems, sensors, and production workflows.

- Customized Industrial Conveyor Solutions: Each conveyor belt system is engineered based on material characteristics, layout requirements, and operational goals rather than using generic designs.

- End-to-End Project Capability: From concept design and manufacturing to installation and commissioning, DNC Automation delivers complete conveyor solutions with consistent quality and accountability.

- Long-Term Reliability and Support: DNC Automation emphasizes durability, easy maintenance, and responsive technical support, helping clients achieve stable operations and lower lifecycle costs.

By choosing a manufacturer with strong engineering expertise, customization capability, and automation-focused design, businesses can achieve higher efficiency, reduced downtime, and long-term operational reliability. Investing in the right partner ensures that conveyor systems support both current production needs and future automation growth.

- 2 views

- 0 Comment

Recent Comments