Spiral Conveyor Systems for Smart Automation Lines

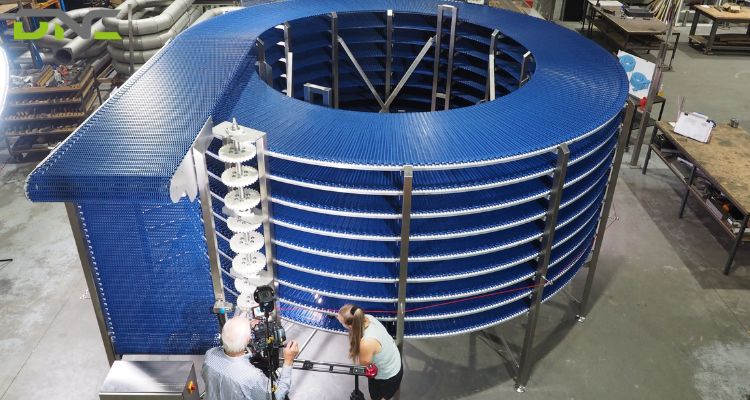

In automated production and material handling environments, efficient vertical movement is essential for maintaining a consistent workflow and maximizing available space. Spiral conveyor systems are engineered to transport products smoothly between different height levels while supporting continuous operation. By utilizing a compact vertical design, these systems eliminate the need for long incline conveyors and complex transfer points.

Spiral conveyors are widely used in manufacturing, packaging, and warehousing applications where space efficiency, throughput stability, and automation compatibility are critical. Their ability to handle a wide range of products makes them a reliable solution for modern vertical automation requirements.

What Is a Spiral Conveyor?

A spiral conveyor is a vertical conveying system designed to transport products upward or downward in a continuous flow along a spiral path. Unlike traditional incline conveyors, spiral conveyors use a compact circular footprint to move items between different elevation levels efficiently.

These systems are commonly used in automated production lines, packaging facilities, and warehouse operations where floor space is limited. Spiral conveyors can handle a wide range of product sizes and weights, making them suitable for both light-duty and heavy-duty industrial applications. Their continuous operation helps maintain throughput consistency while reducing manual handling and congestion.

How Spiral Conveyor Systems Work

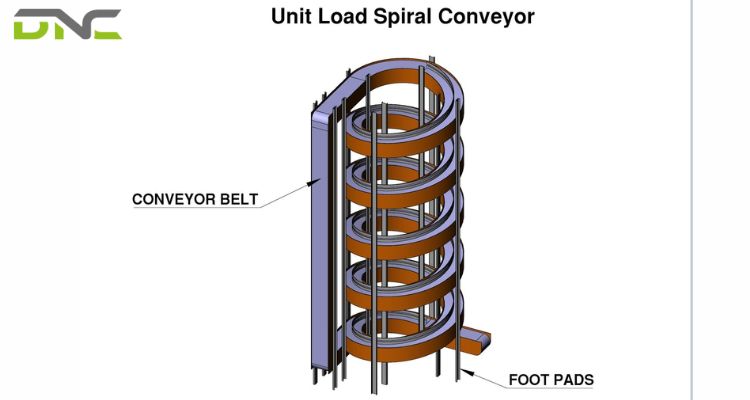

Spiral conveyors operate by guiding products along a helical path using a continuous belt or slat system supported by a central column and outer framework. This design enables smooth vertical movement while maintaining product stability.

- Continuous vertical movement: Products move seamlessly along the spiral track without stopping or transferring between separate conveyor sections. This continuous flow helps reduce bottlenecks and supports high-throughput automation lines.

- Controlled product stability: The spiral design maintains consistent product orientation during elevation changes, minimizing the risk of tipping, slipping, or product damage during transport.

- Upward or downward conveying capability: Spiral conveyors can be configured to move products either upward or downward, allowing flexible integration into different production layouts and material flow requirements.

Key Components of a Spiral Conveyor System

A spiral conveyor system consists of several engineered components that work together to ensure reliable and efficient operation in automated environments.

- Spiral conveyor belt or slat chain: The belt or slat surface is designed to provide sufficient grip and stability for products during vertical movement. Material selection depends on load capacity, hygiene requirements, and operating conditions.

- Central support column: This structural element supports the spiral track and maintains alignment, ensuring smooth motion and long-term system durability.

- Drive and tensioning system: Motors and tensioning mechanisms regulate belt speed and maintain consistent operation, helping prevent slippage and uneven wear.

- Safety guards and side frames: Protective structures enhance operator safety and ensure products remain securely on the conveyor path during operation.

Industrial Applications of Spiral Conveyors

Spiral conveyor systems are widely used across industries that require efficient vertical material movement while maintaining continuous production flow.

- Manufacturing and assembly lines: Spiral conveyors transport components or finished products between different process stages, supporting multi-level production layouts without excessive floor space usage.

- Packaging operations: These systems are commonly used to feed products into packaging machines, accumulate items between processes, or transfer packaged goods to higher-level conveyors.

- Warehousing and distribution centers: Spiral conveyors enable smooth movement of cartons, totes, or parcels between floors, mezzanines, and sorting systems in automated logistics environments.

- Food and beverage processing: With appropriate belt materials and hygienic design, spiral conveyors are suitable for moving packaged food products while maintaining sanitation standards.

Advantages of Using Spiral Conveyor Systems

Spiral conveyors offer several operational and layout benefits compared to traditional vertical conveying solutions.

- Space-saving design: The compact footprint of a spiral conveyor allows vertical transport within a confined area, freeing valuable floor space for other equipment or processes.

- Continuous product flow: Unlike elevators or intermittent lifts, spiral conveyors support uninterrupted movement, improving throughput consistency and reducing cycle time.

- Flexible system integration: Spiral conveyors can be integrated with automated lines, sensors, and control systems, enabling synchronized operation with upstream and downstream equipment.

- Reduced manual handling: Automated vertical transport minimizes the need for manual lifting or transferring, improving workplace safety and operational efficiency.

Spiral Conveyor vs Incline Conveyor Systems

Choosing between a spiral conveyor and an incline conveyor depends on layout constraints, throughput requirements, and available space.

| Comparison Factor | Spiral Conveyor | Incline Conveyor |

|---|---|---|

| Footprint & Layout Efficiency | Uses a compact circular footprint, significantly reducing horizontal space requirements and supporting space-constrained layouts | Requires long conveyor lengths to achieve elevation changes, increasing floor space consumption |

| Elevation Change Capability | Achieves vertical transport over short distances with a continuous spiral path | Needs extended conveyor length to maintain safe incline angles for product stability |

| Throughput Consistency | Maintains continuous, steady product flow, supporting high-throughput automation lines | Throughput may vary due to speed adjustments based on incline angle and product characteristics |

| System Integration | Easily integrates into multi-level automation systems with minimal transfer points | Often requires additional transfer conveyors or transitions |

| Operational Flexibility | Suitable for both upward and downward conveying within compact layouts | More limited when space constraints restrict conveyor length |

Key Factors to Consider When Selecting a Spiral Conveyor

Selecting the right spiral conveyor system requires careful evaluation of operational and technical requirements.

- Product characteristics: Product size, weight, shape, and surface condition influence belt selection, spiral diameter, and system configuration to ensure stable transport.

- Throughput and speed requirements: Conveyor speed must align with production capacity to prevent accumulation issues or flow interruptions.

- Environmental conditions: Temperature, humidity, and cleanliness requirements affect material choices and design features, especially in sensitive processing environments.

- Integration with automation controls: Compatibility with PLC systems, sensors, and safety interlocks is essential for seamless operation within automated production lines.

Maintenance and Safety Considerations

Proper maintenance and safety design are essential to ensure long-term performance and reliability of spiral conveyor systems.

- Routine inspection and cleaning: Regular checks of belts, drives, and support structures help identify wear early and prevent unexpected downtime.

- Accessible maintenance design: Well-designed spiral conveyors provide access points for inspection and servicing without requiring extensive disassembly.

- Safety guarding and compliance: Protective covers, emergency stops, and safety sensors help reduce operational risks and support compliance with industrial safety standards.

Why Is DNC Automation a Trusted Partner for Spiral Conveyor Solutions?

Choosing the right automation partner is just as important as selecting the right spiral conveyor system. A trusted partner ensures that the conveyor solution aligns with operational goals, layout constraints, and long-term automation strategies.

DNC Automation delivers spiral conveyor solutions through:

- Automation-focused system design: Each spiral conveyor is engineered to integrate seamlessly with automated production lines, control systems, and material handling workflows.

- Customized application solutions: Conveyor systems are tailored to specific product characteristics, throughput requirements, and facility layouts rather than relying on generic designs.

- End-to-end project support: From system design and integration to commissioning and after-sales support, DNC Automation provides comprehensive assistance throughout the project lifecycle.

If you are planning to upgrade or implement a spiral conveyor system, contact DNC Automation now to discuss your application requirements and receive a solution designed for long-term automation performance and operational efficiency.

- 1 views

- 0 Comment

Recent Comments