AGV and AMR Systems – Which Mobile Robot Solution Fits Your Warehouse Best?

AGV (Automated Guided Vehicle) and AMR (Autonomous Mobile Robot) systems are revolutionizing warehouse and factory operations by automating material transport, improving accuracy, and reducing manual labor. With proven expertise in automation and system integration, DNC Automation delivers end-to-end AGV and AMR solutions that enhance productivity, safety, and scalability for businesses across Malaysia.

What Are AGV and AMR Systems?

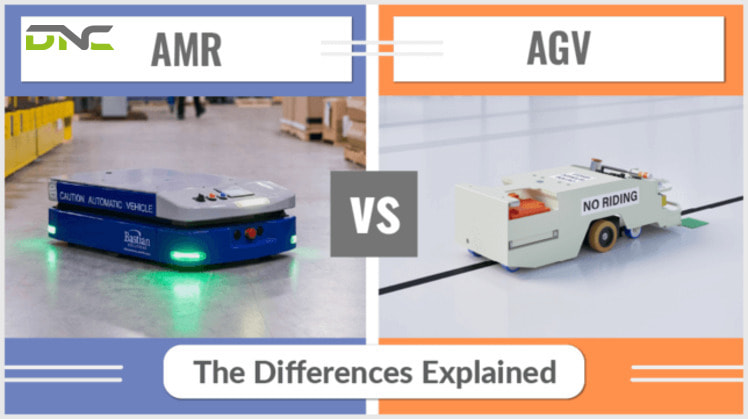

In today’s automated warehouses and factories, mobile robots play a crucial role in improving material flow and reducing manual handling. Among these technologies, AGV (Automated Guided Vehicle) and AMR (Autonomous Mobile Robot) are two of the most widely used systems — each serving different operational needs.

AGVs are mobile vehicles that move along fixed routes, guided by magnetic tapes, laser reflectors, or QR markers installed on the warehouse floor. They are ideal for structured environments where material flow is consistent and predictable. AGVs are known for their stability, repeatability, and safety in repetitive transport tasks such as pallet movement or line feeding.

AMRs, on the other hand, are equipped with advanced sensors, LiDAR, and SLAM (Simultaneous Localization and Mapping) technology, allowing them to navigate freely without physical guides. They use onboard intelligence and AI-based obstacle detection to calculate the most efficient path in real time. This makes AMRs more suitable for dynamic environments where layouts or workflows may frequently change.

AGV (Automated Guided Vehicle) and AMR (Autonomous Mobile Robot)

What Are the Key Differences Between AGV and AMR?

Although both AGVs and AMRs automate material handling, they operate on different levels of intelligence, flexibility, and infrastructure needs. Understanding these differences will help you select the right solution for your specific warehouse layout and workflow.

| AGV (Automated Guided Vehicle) | AMR (Autonomous Mobile Robot) | |

| Navigation Method | Follows fixed paths using magnetic tape, QR codes, or laser guidance. | Uses sensors, LiDAR, and SLAM mapping for free, intelligent navigation. |

| Infrastructure Requirement | Requires physical guides or markers on the floor. | No physical guides needed; relies on digital mapping and real-time perception. |

| Flexibility | Limited — route changes require physical modification. | Highly flexible — can adapt instantly to layout or workflow changes. |

| Environment Suitability | Best for structured, predictable operations. | Ideal for dynamic, mixed-traffic environments. |

| Obstacle Handling | Stops when encountering obstacles until the path is cleared. | Detects and navigates around obstacles automatically. |

| Setup Cost & Time | Lower upfront cost but less adaptable. | Higher initial investment but greater long-term efficiency. |

| Integration with Other Systems | Integrates with WMS/WCS through predefined paths. | Integrates seamlessly with WMS/WCS using real-time data communication. |

| Best Use Cases | Repetitive transport tasks, production line feeding, pallet movement. | Dynamic picking zones, order fulfillment, cross-dock transport. |

8 Key Differences Between AGV and AMR

Why Are Mobile Robots Transforming Warehouse and Factory Operations?

As industries move toward smart manufacturing and digitalized logistics, mobile robots such as AGVs and AMRs are revolutionizing how materials flow within facilities. They not only boost productivity but also create safer, more responsive, and cost-efficient operations — helping businesses stay competitive in the age of Industry 4.0.

- Continuous 24/7 operation with minimal downtime and consistent performance.

- Reduced human error and enhanced workplace safety through automation.

- Faster material transport between production lines and warehouse zones.

- Adaptability to changing demand and labor availability.

- Seamless integration with WMS and WCS for real-time coordination and data-driven decision-making.

AGVs and AMR boost productivity and cost-efficient operations

What Are the Common Use Cases of AGV and AMR Systems?

AGV and AMR technologies are now integral to modern intralogistics, optimizing every step of material movement within warehouses and factories. From pallet handling to intelligent picking, these systems streamline workflows, reduce manual labor, and improve operational efficiency.

- Pallet transport between receiving, storage, and shipping zones.

- Automated put-away and retrieval in racking or AS/RS systems.

- Goods-to-person picking and order fulfillment for e-commerce and manufacturing.

- Inter-process transport between production, packaging, and dispatch areas.

- Hybrid applications, combining AGVs for heavy-duty tasks and AMRs for flexible, dynamic workflows.

Pallet transport between receiving, storage, and shipping zones.

Challenges in Implementing AGV and AMR Systems Initial infrastructure and software investment.

While AGV and AMR technologies bring efficiency and precision to warehouse and factory operations, their implementation can be complex. Businesses must consider various technical and operational factors to ensure successful deployment and long-term performance.

- Initial Infrastructure and Software Investment: Implementing AGV and AMR systems often requires significant upfront costs for hardware, navigation infrastructure, and control software. Facilities may need to modify layouts, upgrade networks, and install sensors or safety systems.

- Compatibility with Existing WMS, WCS, and ERP Systems: Integrating AGVs and AMRs into existing digital ecosystems can be challenging.

- Floor Quality, Lighting, and Environmental Conditions: The performance of mobile robots heavily depends on the operating environment. Uneven floors, reflective surfaces, inconsistent lighting, or cluttered pathways can interfere with sensors and LiDAR navigation.

- Fleet Management, Battery Life, and Maintenance Planning: Companies must monitor real-time status, schedule charging cycles, and plan predictive maintenance to avoid downtime.

Integrating AGVs and AMRs into existing digital ecosystems can be challenging.

Why Choose DNC Automation for AGV and AMR Integration?

As the demand for efficiency, accuracy, and flexibility continues to grow, AGV and AMR systems have become essential components of modern factories and warehouses. These technologies not only automate repetitive transport tasks but also enable real-time coordination, optimized workflows.

At DNC Automation, we specialize in end-to-end automation solutions, from mobile robot integration (AGV & AMR) to conveyor systems, WMS/WCS integration, and robotic picking applications.

With over a decade of experience and a team of expert engineers, we help manufacturers and logistics providers design, implement, and maintain automation systems that deliver measurable performance and long-term ROI.

- 3 views

- 0 Comment

Recent Comments