Bucket conveyor system: classification, advantages, best cost…

Bucket conveyors are specialized equipment used to move materials vertically at a speed of about 3~5 feet per second. The conveyor is designed to be used continuously and automatically, with a simple operating principle of collecting and dumping raw materials. It can be said that bucket conveyors are one of the important machines in many warehouses.

What is the bucket conveyors?

In addition, the equipment has a variety of different prices with many classifications such as: continuous bucket, positive discharge, centrifugal conveyors, … with each classification having different characteristics, operating capabilities and prices.

Let’s learn more about this equipment with DNC Automation in the following article:

How is the bucket conveyor structured and operated?

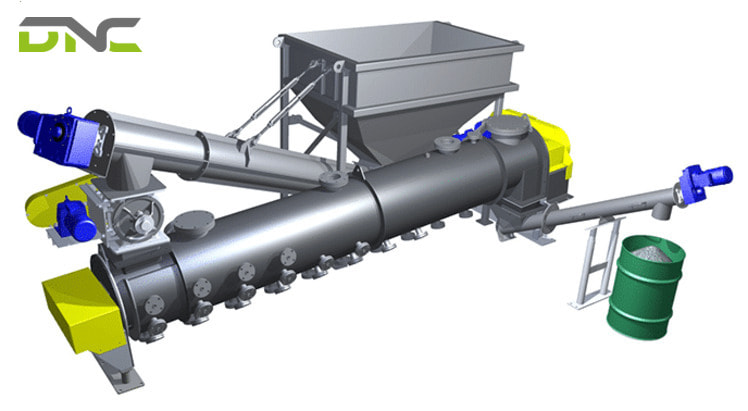

The bucket conveyor consists of buckets connected together in a vertical chain. The device operates by using a reciprocating bucket, the purpose of which is to transport goods up and down in a certain direction.

How bucket conveyor works?

In addition, the bucket conveyor is operated automatically and quickly, supporting the collection and dumping of raw materials, the device will work best in transporting dry, light, and powdery materials. Limit the use of wet materials, which can easily adversely affect the discharge capacity of the device.

How much does it cost to install the bucket conveyors?

Is the cost of a bucket conveyor expensive or cheap? This is a difficult question because many factors affect the installation cost of the conveyor such as:

Bucket conveyor installation cost

- Components and materials used: depending on the material used for the bucket, there will be many different prices. More expensive materials such as steel and stainless steel will increase the bucket conveyor’s cost.

- Capacity and size of the chain: systems that require higher capacity and larger sizes will often come with a higher cost than those with smaller capacities.

- Maintenance and installation issues: do not rush to ignore the cost of installation and maintenance, because this is a significant expense in the total cost of the conveyor.

- Customization and design capabilities: for conveyors with complex designs and high requirements for self-adjustment, the initial investment cost will be higher.

But generally speaking, the price range for a bucket conveyor will range from $2,000 to $8,000.

Continuous Bucket Conveyors

The equipment is specially designed for light and fragile materials without clearance between buckets. The equipment is uniquely arranged in Z, C or S style with operating speed of about 3~5 feet per second, very effective in handling materials such as: recycled glass, sand, gravel, ore, crushed stone…

Positive Discharge Conveyors

This is considered a special type of centrifugal conveyor, moving at a slower speed of about 2~4 feet per second, minimizing spillage of raw materials. Active discharge conveyors are very suitable for handling raw materials such as grains, seeds, dried fruits… products that emphasize the integrity and quality of the product.

Centrifugal Bucket Conveyors

With its relatively high travel speed, the centrifugal bucket conveyor allows the material to be pushed out of the bucket and into the discharge hole very easily. This equipment is especially suitable for small, fine lumpy materials that can withstand being scooped out of the bucket and thrown out the discharge pipe.

What are the applications of bucket conveyors?

Bucket conveyors are widely used in various industries such as:

- Cement production and packaging

- Production of pulp and paper, wood chips.

- Industries such as fertilizers, and animal feed production are also being applied more and more widely.

- Heavy and hard-to-find materials such as those used in mineral mining activities…

What are the outstanding advantages of Bucket Conveyors?

Like other types of conveyors, bucket conveyors bring many outstanding advantages to the production line, including:

Outstanding advantages of bucket conveyor

- Innovative configuration: the device has a special appearance located in a certain vertical direction, saving warehouse space and meeting many separate requirements for many different projects.

- Easy transportation: because it is a highly automated device, with just a few simple operations, the system will operate automatically, and move large quantities of materials easily.

- Larger capacity: Depending on the size of the hopper and bucket, large buckets will be safer for transporting materials without worrying about spillage.

- Cost savings: bucket conveyors are considered a great investment for many production facilities, thanks to their self-operating ability and high endurance with outstanding performance. This is the device that helps manufacturers optimize labor costs and effectively save costs for businesses.

What should be noted during the use of the bucket conveyor?

Here are some things to keep in mind to ensure your bucket conveyor is durable and efficient for a long time:

- Regularly inspect, lubricate, and maintain the system to ensure the equipment always performs at its best.

- Follow the manufacturer’s instructions and operating methods to avoid unexpected damage.

- Contact a qualified technician or contact the manufacturer directly as soon as you notice any unusual signs of the equipment such as loud noises, malfunctions during operation, excessive wear and tear, etc.

- Experienced and qualified technicians must be present to operate and supervise the entire process.

- 169 views

- 0 Comment

Recent Comments