Conveyor Belt Motors: Types, Selection & Efficiency

Many conveyor systems struggle with inconsistent speed, excessive energy consumption, frequent breakdowns, or limited automation compatibility. In most cases, these problems stem from an unsuitable or poorly matched motor rather than the conveyor structure itself. Conveyor belt motors are the driving force behind material handling performance, directly influencing throughput, reliability, and operating costs. Selecting the..

Read more- 6 views

- 0 Comment

Feeder Conveyor: Types, Benefits, and Industrial Uses

In automated production lines, inconsistent material flow is one of the most common causes of downtime, inefficiency, and quality issues. Many manufacturers struggle with uneven feeding, material spillage, or bottlenecks between processes. A poorly selected conveyor system can disrupt the entire workflow and reduce productivity. This is where a feeder conveyor becomes essential. Designed to..

Read more- 4 views

- 0 Comment

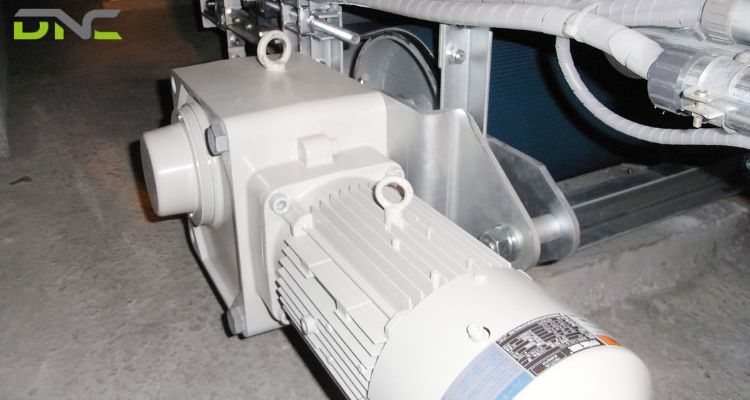

Conveyor Gearbox: Essential Guide for Efficient Conveyor Systems

In automated conveyor systems, performance issues such as uneven speed, excessive vibration, frequent breakdowns, and high energy consumption often trace back to one critical component: the gearbox. Choosing the wrong conveyor gearbox can lead to reduced efficiency, higher maintenance costs, and unexpected downtime that disrupts production flow. Engineers and system owners increasingly demand gearbox solutions..

Read more- 1 views

- 0 Comment

Polyurethane Conveyor Belt for Automated Systems

In automated production environments, conveyor belt failure can cause costly downtime, hygiene risks, and inconsistent product flow. Many manufacturers struggle with belts that wear quickly, absorb contaminants, or fail to meet strict industry standards. A polyurethane conveyor belt addresses these challenges by offering superior durability, hygienic performance, and compatibility with modern automation systems. Designed for..

Read more- 2 views

- 0 Comment

Conveyor Wheels for Efficient Material Handling Systems

In material handling operations, inefficient product flow, excessive manual handling, and frequent conveyor downtime can significantly impact productivity and operational costs. Many facilities struggle to select the right conveyor components that balance load capacity, durability, and system efficiency. Conveyor wheels play a critical role in ensuring smooth movement, controlled flow, and reliable performance within conveyor..

Read more- 5 views

- 0 Comment

Scraper Conveyor Systems for Heavy-Duty Material Handling

Handling abrasive, hot, or heavy bulk materials is a constant challenge in industrial environments. Material spillage, excessive dust, frequent maintenance, and system downtime can quickly impact productivity and operational costs. Many facilities struggle to find a conveying solution that is reliable, enclosed, and capable of operating continuously under harsh conditions. This is where scraper conveyor..

Read more- 0 views

- 0 Comment

Wire Mesh Conveyor Belt: Benefits, Applications, and Types [Updated 2026]

In modern automated production environments, material handling inefficiencies often lead to downtime, hygiene risks, and inconsistent product flow. Many facilities struggle to find conveyor solutions that can withstand high temperatures, support continuous airflow, and remain easy to clean. This is where a wire mesh conveyor belt becomes a critical component. Designed for demanding industrial conditions,..

Read more- 1 views

- 0 Comment

Flexible Conveyor Systems for Smart Automation Flow

Modern production and logistics operations face constant pressure to increase efficiency while adapting to changing layouts, fluctuating volumes, and limited floor space. Fixed conveyor systems often lack the flexibility required to support these dynamic conditions, leading to inefficiencies, manual handling, and higher operational costs. A flexible conveyor system addresses these challenges by offering mobility, scalability,..

Read more- 0 views

- 0 Comment

Motorized Conveyor Rollers for Advanced Automation

Modern production and warehouse operations face constant pressure to move goods faster, reduce downtime, and cut energy consumption without increasing system complexity. Traditional conveyor drives often struggle to keep up with flexible layouts, zoning requirements, and automation integration demands. This is where motorized conveyor rollers provide a smarter solution. By combining the drive motor directly..

Read more- 1 views

- 0 Comment

Incline Conveyor Systems for Efficient Material Handling

Incline conveyor systems play a critical role in modern automated production environments by enabling smooth material transfer between different height levels. Designed to optimize space, improve workflow efficiency, and support automation integration, incline conveyors are widely used across manufacturing, warehousing, and logistics operations. What Is an Incline Conveyor? An incline conveyor is a material handling..

Read more- 2 views

- 0 Comment

![Wire Mesh Conveyor Belt: Benefits, Applications, and Types [Updated 2026]](https://www.dnc-automation.com/wp-content/uploads/2026/01/Wire-Mesh-Conveyor-Belt.jpg)

Recent Comments