Predictive Maintenance: The Future of Smart Warehouses

Predictive maintenance is reshaping how warehouses operate. As facilities become smarter and more connected, predictive maintenance allows businesses to predict equipment failures before they occur ensuring seamless operations, higher productivity, and reduced costs.

This technology-driven approach is quickly becoming the foundation of smart warehouse automation, combining IoT sensors, data analytics, and real-time monitoring to maximize uptime and efficiency.

What Is Predictive Maintenance in Warehousing?

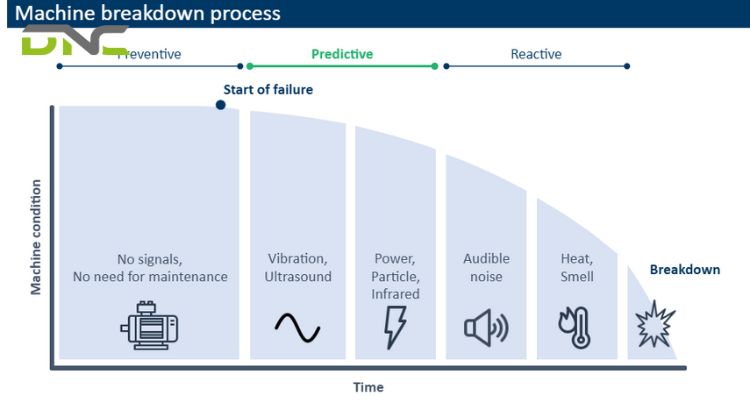

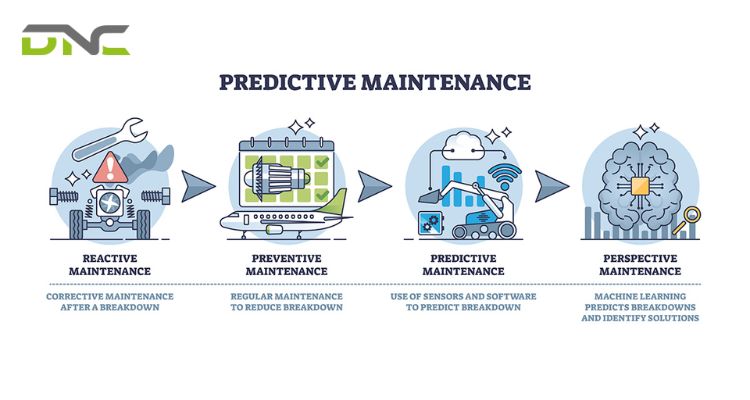

Predictive maintenance (PdM) is a data-driven strategy that uses sensors and advanced analytics to detect early signs of wear, deterioration, or failure in warehouse equipment. Unlike reactive or scheduled maintenance, PdM allows operators to service machinery only when necessary, based on the actual condition of the equipment.

In modern warehouses, predictive maintenance systems continuously monitor assets such as conveyors, automated storage systems, and AGVs (Automated Guided Vehicles), helping to identify potential failures before they cause unplanned downtime, creating a safer, smarter, and more cost-effective environment.

What are the Components of a Predictive Maintenance System?

An effective predictive maintenance system combines several technological layers to collect, process, and act on real-time equipment data.

- Vibration Sensors: Mounted on motors, conveyors, and gearboxes, vibration sensors detect abnormal mechanical movements or imbalances often the first indicators of bearing wear or misalignment.

- Temperature and Humidity Sensors: Environmental factors can directly affect equipment performance. These sensors help identify overheating components or environmental stress conditions in warehouse environments.

- Edge Computing Devices: Edge computing enables fast, local data processing near the equipment source. It minimizes latency and allows immediate fault detection without relying entirely on cloud processing.

- Real-Time Monitoring Dashboards: Supervisors can view machine health in real time through CMMS (Computerized Maintenance Management Systems) or integrated HMI (Human-Machine Interface) dashboards, allowing quick response to alerts.

- Cloud Analytics Platforms: Data from IoT devices are stored and analyzed in the cloud. AI models then predict potential failures and recommend optimized maintenance schedules.

What are the Components of a Predictive Maintenance System?

How Does Predictive Maintenance Warehouse Work?

Predictive maintenance systems continuously gather equipment data such as vibration, temperature, and voltage through IoT sensors. This data is processed via edge computing devices and then transmitted to cloud analytics platforms for deeper insights.

Machine learning algorithms analyze patterns and detect anomalies that indicate possible issues. Maintenance teams receive automated alerts through the CMMS or HMI interface, allowing them to perform targeted inspections before breakdowns occur.

This proactive approach ensures warehouse uptime, smooth logistics flow, and reliable order fulfillment even in high-demand seasons.

How Does Predictive Maintenance Warehouse Work?

What are the Benefits of Predictive Maintenance for Warehouse Operations

Predictive maintenance gives warehouses a proactive edge — helping prevent costly downtime, extend equipment lifespan, and ensure a safer workplace. By using real-time data and automated monitoring, facilities can achieve smoother operations, stronger ROI, and better employee performance.

- Minimizing Downtime and Equipment Failure: Predictive maintenance supports equipment health monitoring to detect faults early. By addressing small performance issues before they escalate, warehouses maintain higher uptime and avoid sudden disruptions in production.

- Extending Equipment Lifespan and Reducing Maintenance Costs: Through maintenance optimization, predictive systems adjust service schedules based on actual equipment conditions. This approach improves cost efficiency and delivers measurable ROI by minimizing unnecessary repairs and maximizing asset lifespan.

- Enhancing Worker Safety and Productivity: With predictive safety monitoring and automated alerts, workers are warned of equipment risks in advance. This leads to a safer, more stable environment and greater operational efficiency

How Predictive Maintenance Integrates with Warehouse Automation Systems

Predictive maintenance is the backbone of modern warehouse automation, ensuring every system from conveyors to ASRS and AGVs operates at peak reliability. By integrating IoT sensors, SCADA systems, and cloud analytics, warehouses gain full visibility and control over equipment performance.

- Integration with ASRS, AGVs, and Conveyor Systems: Advanced sensors and analytics track vibration, motor load, and navigation accuracy in ASRS, AGVs, and conveyors. Early anomaly detection enables maintenance teams to take action before faults occur, ensuring continuous operation and maximizing throughput.

- The Role of SCADA and HMI in Predictive Maintenance: SCADA and HMI platforms provide real-time visualization of temperature, vibration, and motor data. Integrated HMI dashboards deliver instant alerts and performance trends to help technicians prevent costly downtime.

- Data Flow Between IoT Devices and Cloud Analytics: A robust IoT connectivity network links sensors, edge devices, and cloud servers. Edge computing processes data instantly, while cloud maintenance analytics predict long-term trends — paving the way toward fully autonomous warehouse operations.

How Predictive Maintenance Integrates with Warehouse Automation Systems

How to Choose the Right Predictive Maintenance Partner in Malaysia

As one of the leading warehouse automation specialists in Malaysia, DNC Automation provides comprehensive predictive maintenance solutions that seamlessly integrate with ASRS, conveyors, AGVs, and SCADA systems.

Here’s why businesses choose DNC Automation:

- Comprehensive expertise: Extensive knowledge in Industrial Automation, Robotics and Smart Warehouse Integration with over 10 years of industry experience.

- Customized solutions: Predictive maintenance systems are tailor-made to suit specific operational needs.

- On-site support: Providing on-site technical support and system optimization across Malaysia.

- Professional consulting team: making it easy for you to make the right choice that will increase uptime, save costs and ensure long-term reliability for your automated warehouse operations.

With DNC Automation, you can prepare your warehouse for the future and take a big step towards automation readiness.

- 6 views

- 0 Comment

Recent Comments