Roller Chain Conveyor Systems: Design, Types, and Industrial Applications

Roller chain conveyors are designed for transporting heavy and palletized loads in industrial environments where strength and load stability are critical. By using chain-driven rollers, these systems provide controlled movement and reliable positioning across automated production and material handling lines.

What Is a Roller Chain Conveyor and How Does It Work?

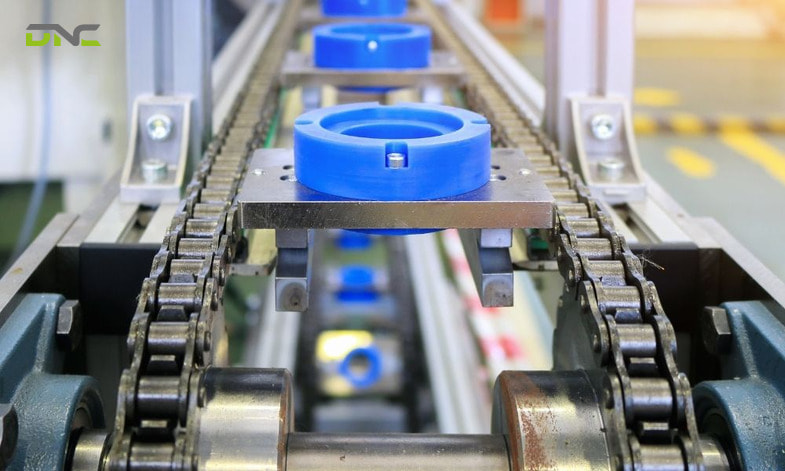

A roller chain conveyor is a type of powered conveyor system designed to transport heavy, rigid loads using chains equipped with rollers. Unlike belt conveyors that rely on friction, roller chain conveyors transmit motion through mechanical engagement between chains, sprockets, and rollers.

The system operates by driving one or more chains via a motor and sprocket assembly. Rollers mounted on the chains support the load directly, allowing pallets, fixtures, or heavy components to move smoothly along the conveyor path. Load movement is discrete and controlled, making roller chain conveyors ideal for indexed or stop-and-go operations.

Why Are Roller Chain Conveyors Used in Industrial Applications?

Roller chain conveyors are commonly selected for environments where strength, durability, and load stability are critical.

- High load capacity: The chain-driven design allows the system to handle heavy and concentrated loads without slippage.

- Mechanical reliability: Positive engagement between chain and sprocket ensures consistent motion, even in harsh environments.

- Stable pallet handling: Loads remain firmly supported, reducing shifting or misalignment during transport.

- Suitability for industrial conditions: They perform well in dusty, oily, or high-impact settings where belt conveyors may degrade faster.

Roller chain conveyors are commonly selected for environments where strength, durability, and load stability are critical.

What Are the Main Types of Roller Chain Conveyors?

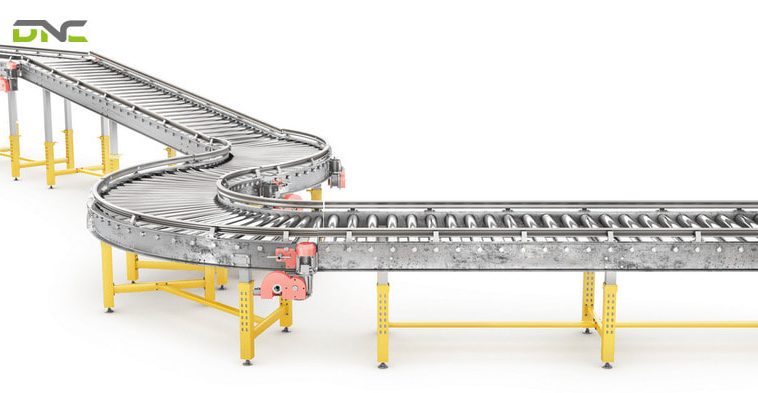

Roller chain conveyors can be configured in several ways depending on load characteristics, pallet geometry, and overall system layout. Each configuration affects load stability, system complexity, and operational flexibility.

- Single-strand roller chain conveyors: This configuration uses a single chain line to transport loads that are narrow or well-centered on the conveyor. It is typically applied where pallet width is limited and load distribution is predictable.

- Double-strand roller chain conveyors: Double-strand conveyors employ two parallel chain lines to provide balanced support for wider or heavier pallets. By distributing weight across both chains, this configuration improves load stability and reduces stress on individual components.

- Multi-strand chain conveyors: Multi-strand configurations utilize three or more chain lines to support very large, heavy, or irregularly shaped loads. This design allows even weight distribution across the conveyor width, minimizing point loading and structural deformation.

- Accumulating roller chain conveyors: Accumulating roller chain conveyors are designed to allow pallets to queue in defined zones without continuous movement. These systems incorporate control mechanisms that maintain spacing and prevent load collision during accumulation.

Each configuration affects load stability, system complexity, and operational flexibility.

How Are Roller Chain Conveyors Classified by Chain and Roller Design?

Chain and roller design directly influence load capacity, operational stability, wear behavior, and long-term maintenance requirements of a roller chain conveyor. Selecting the correct combination is essential to ensure reliable performance under continuous industrial operation.

- Chain size and pitch: Chain size and pitch determine the conveyor’s load-carrying strength and tensile capacity. Larger chains with longer pitch can withstand higher loads and shock forces, making them suitable for heavy-duty applications.

- Roller type: Roller material and construction significantly affect durability and operating conditions. Steel rollers provide high strength and resistance to deformation under heavy loads, making them ideal for industrial environments.

- Fixed vs free-spinning rollers: Free-spinning rollers reduce friction during transfers, while fixed rollers improve load control.

- Roller spacing and attachments: Roller spacing plays a critical role in load distribution and structural integrity. Proper spacing ensures that the load is supported evenly, minimizing point loading that can cause roller damage or pallet deflection.

Which Industries Commonly Use Roller Chain Conveyors?

Roller chain conveyors are widely used in industries where heavy, rigid, or palletized loads must be transported with high stability and predictable motion. In these environments, mechanical reliability and load control are prioritized over speed or flexibility.

- Automotive and component assembly

- Heavy manufacturing and metal processing

- Palletized warehousing systems

- Packaging lines for large or rigid products

- Machinery and equipment assembly operations

Across these industries, roller chain conveyors are selected not for maximum speed, but for their ability to deliver consistent load handling, structural reliability, and long-term operational stability in demanding industrial environments.

Automotive and component assembly

What Are Common Problems and Limitations of Roller Chain Conveyors?

Despite their strength and reliability, roller chain conveyors have inherent problems and limitations that should be considered during system design and operation.

- Chain wear and elongation: Continuous heavy loads and repetitive motion cause chains to gradually stretch over time. This elongation affects sprocket engagement, leading to uneven motion and increased maintenance requirements.

- Higher noise and vibration levels: Metal-to-metal contact between chains, rollers, and sprockets generates more noise and vibration compared to belt-based systems. This can be a concern in environments where noise control is important.

- Regular lubrication and maintenance needs: Roller chain conveyors require consistent lubrication to reduce friction and wear. Inadequate lubrication accelerates component degradation, while excessive lubrication may attract dust and contaminants.

- Limited operating speed: Due to mechanical engagement and load characteristics, roller chain conveyors are generally unsuitable for high-speed conveying. Higher speeds increase wear, noise, and the risk of mechanical failure.

- Reduced flexibility for layout changes: These systems are often designed for specific pallet sizes and load paths. Modifying layouts or accommodating new products may require mechanical redesign rather than simple adjustment.

Understanding these limitations allows engineers to design roller chain conveyor systems that prioritize durability and reliability while minimizing operational risks over the long term.

What Are Common Problems and Limitations of Roller Chain Conveyors?

Why Choose DNC Automation for Roller Chain Conveyor System Design?

From a system engineering perspective, effective roller chain conveyor design goes beyond selecting components.

- Experience in heavy-duty conveyor applications

- System-level design focused on load behavior and automation flow

- Integration capability with PLCs and automated equipment

- Emphasis on durability, safety, and long-term operational stability

DNC Automation approaches roller chain conveyors as part of a complete material handling and automation ecosystem.

- 9 views

- 0 Comment

Recent Comments