Learn the Important Specifications of Vacuum Conveyor

Vacuum Conveyor is a closed vacuum material transport system, helping to increase productivity and ensure absolute hygiene. With a capacity of up to 5,000 kg/hour, a maximum transport distance of 50 meters, this device is suitable for food, pharmaceutical, chemical and plastic factories. This article by DNC Automation will help you understand the operating principles, outstanding advantages and how to choose the right vacuum conveyor for each production process.

What is a vacuum conveyor?

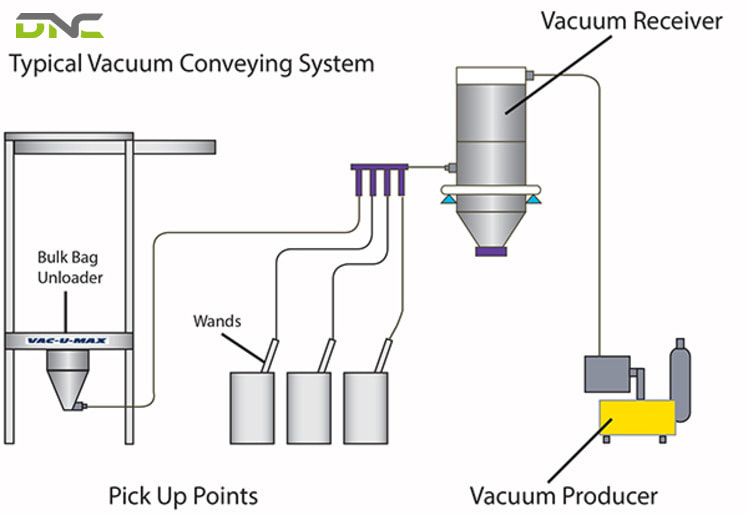

A vacuum conveyor is a device used to transport bulk materials, such as powders, granules, tablets, etc., by using negative pressure (vacuum) to suck and move the material through a closed pipe system.

During operation, the vacuum pump creates a low-pressure air stream, sucking the material from the hopper or container into the system. The material is then directed to the destination such as a packaging machine, mixer, or storage silo.

Vacuum Conveyor Specifications

Depending on the model and application needs, vacuum conveyors will have different specifications. Below is a common parameter table for a standard vacuum conveyor system:

| Conveying capacity | 100 – 5,000 kg/hour (depending on model) |

| Conveying distance | Maximum 20 – 50 meters (horizontal or vertical) |

| Power source | 220V/380V – 50Hz |

| Materials Stainless | steel 304 / 316, aluminum, or painted steel |

| Suction pipe | Ø38mm, Ø50mm, Ø76mm or customized |

| Vacuum pump capacity | 1.5 – 15 kW |

| Suitable raw material | Powder, granules, pellets, bulk materials |

| Integration capability | Can be connected to silos, mixers, packaging machines, PLCs… |

| Hygiene standards | Meet GMP, HACCP standards (if any) |

How does a Vacuum Conveyor work?

Vacuum conveyors operate on the principle of creating a vacuum (negative pressure) to suck and move materials from one point to another in a closed system. The entire transportation process usually takes place in cycles and is automatically controlled through a central controller or PLC.

The basic operating cycle of a Vacuum Conveyor includes the following 4 steps:

Step 1: Create a vacuum and suck materials

- A vacuum pump (or ejector) will create low pressure inside the chamber.

- Thanks to the pressure difference between the outside environment and inside the chamber, the materials are sucked from the feeding hopper or container through the pipe into the device.

Step 2: Transporting raw materials to the destination

- The raw materials move along the air flow in the closed pipe system and are brought to the temporary storage chamber or directly to the equipment used such as mixers, packaging machines, storage silos, etc.

Step 3: Discharging raw materials

- When the raw materials have been transferred in sufficient quantity, the system will stop suction and open the discharge valve to discharge the raw materials.

- The discharge valve can be operated by compressed air or electricity depending on the design of the system.

Step 4: Cleaning the filter and restarting the cycle

- After each suction-discharge cycle, the filter will be cleaned by reverse compressed air flow to ensure suction performance for the next cycle.

- The system continues to operate continuously and automatically, repeating the above steps.

The basic operating cycle of a Vacuum Conveyor includes the following 4 steps

Why should businesses use a Vacuum Conveyor?

Vacuum conveyor is not only a simple material transport device, but also an optimal solution to help improve production efficiency, ensure safety and minimize risks in the factory. Below are the outstanding advantages that make this device increasingly popular:

- Clean and dust-free transport: The completely closed operating system helps prevent dust from spreading into the environment, especially useful in industries that require high hygiene standards such as food, pharmaceuticals or chemicals.

- Reduce material loss during transportation: Thanks to the closed system and the ability to control the flow of materials precisely, vacuum conveyors help reduce loss, spillage and optimize the efficiency of material use – especially important for high-value materials.

- Easy to clean and maintain: Most modern vacuum conveyors are designed to be quickly disassembled, easy to clean and do not require much maintenance time.

- Safety for users: With the ability to transport automatically and without direct contact with raw materials, vacuum conveyors help minimize the risk of inhaling toxic dust or contact with irritating substances.

- Increase production capacity: Vacuum conveyors operate continuously and stably, and can be integrated into automatic lines to quickly transport raw materials between stages.

- Easy integration: The equipment can be easily connected to packaging machines, mixers, silos, or PLC control systems to form a closed chain.

Benefits of Vacuum Conveyor

Notes when choosing a Vacuum Conveyor for the factory?

For the vacuum conveyor system to maximize its efficiency in the production process, choosing the right equipment for the operating characteristics and type of raw material is a key factor. Below are some important criteria to consider before investing:

- Determine the type of material to be transported: Businesses need to determine the type of material that their factory produces such as fine powder, granular materials, or materials that are easy to clump…

- Flow rate and transport capacity: Based on the amount of raw material needed to be supplied per hour, you can determine how much capacity the vacuum conveyor needs (usually calculated in kg/h or tons/h).

- Transport distance and height: It is necessary to determine the distance from the suction point to the discharge point (both horizontal and vertical). For long distances or high altitudes, you should choose equipment with stronger suction pressure, or add intermediate support units.

- Level of automation and integration capabilities: If the factory is using an automated line, it is advisable to choose a device line that can connect control signals, material level sensors, warning signals, etc.

- Investment budget and operating costs: A system with a standard configuration will fit the average budget, while a system requiring customization will require a separate quote.

Notes when choosing a Vacuum Conveyor for the factory?

Where to buy reputable automatic vacuum conveyor lines?

If you are uncertain about where to purchase a vacuum conveyor, DNC Automation is an excellent option for you. Many customers have trusted DNC to provide automation solutions in the production process and have had positive experiences because:

- DNC is a leading technology, automation, and engineering company in Malaysia with over 15 years of experience in the field of automation

- System integration machinery, Internet of Things (IoT), Industry 4.0, and WinCC Scada System

- Diverse designs and sizes are suitable for many domestic and foreign houses. The equipment is 100% genuine and imported from Malaysia.

Please contact us via the hotline below if you have any questions about the product, we are happy to answer you!

- 26 views

- 0 Comment

Recent Comments