OSHA Safety Regulations for Warehouse Racking Systems You Need to Know

Warehouse racking system is a storage shelf system designed to organize, preserve and optimize warehouse space. These systems help store goods in an orderly, easy-to-manage manner, while increasing operational efficiency during the import, export and inventory processes.

What are OSHA requirements for warehouse racking?

OSHA (Occupational Safety and Health Administration) does not have a specific set of standards for racking systems, but it does have general regulations and guidelines to ensure the safety of workers and the warehouse environment. These requirements are mainly contained in section 29 CFR 1910 – General Industry Regulations.

Here are the important OSHA requirements for racking systems:

- The racking system must be installed properly: The racking must be installed according to the manufacturer’s technical design. Do not arbitrarily expand or change the structure without technical approval.

- Do not exceed the design load: Each floor or pallet has a maximum load limit. There must be a load warning sign posted in a visible place.

- Maintain safe aisles and distances: The aisles between rows of racks must be wide enough for forklifts to operate. Exits must always be spacious, clear and unobstructed.

- Regular inspection and maintenance: The shelving system must be inspected regularly for warping, rust, and cracks. If a problem is detected, it must be discontinued and repaired promptly.

OSHA requirements for racking systems

What is the role of the shelf system in the warehouse?

The warehouse shelf system not only helps to arrange goods neatly but also optimizes the area, increases operating efficiency and supports automatic equipment. Below are the outstanding roles of the shelf system in the warehouse:

- Optimizing storage area: The shelf system helps to maximize the warehouse space, especially the height, helping to increase capacity without expanding the warehouse area.

- Increasing the speed of picking goods: Goods are classified and arranged scientifically, making it easy to retrieve and reducing the time for importing and exporting goods, improving warehouse operating efficiency.

- Improving labor safety: Minimizing manual stacking, avoiding broken goods, and reducing the risk of accidents in the warehouse.

- Supporting automation equipment: Modern shelf systems can be combined with equipment such as forklifts, conveyors, and picking robots (AS/RS), helping to optimize the process and enhance warehouse automation.

How to install warehouse racking?

The installation of warehouse racking systems must be done accurately, ensuring proper techniques and safety in operation. The basic process usually includes the following steps:

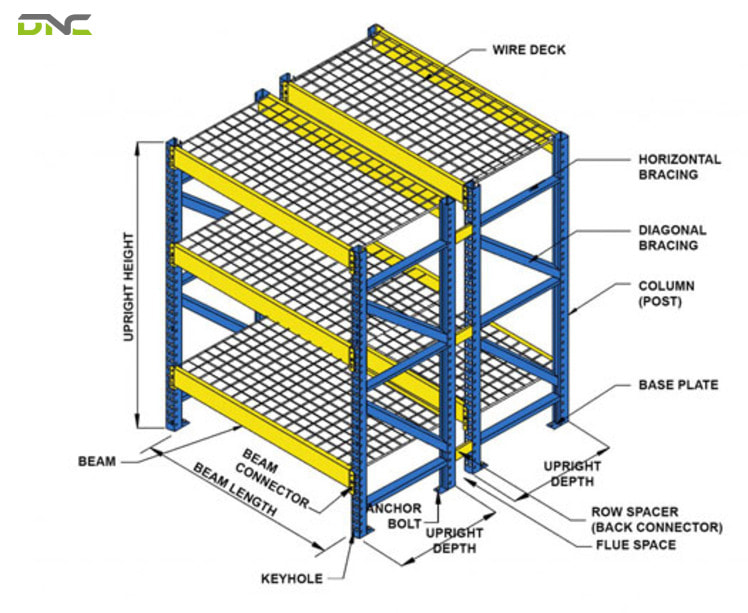

The warehouse racking installation process begins with a survey of the site and the design of a racking layout suitable for the area, type of goods and means of operation. Then, components such as pillars, beams, cross braces, etc. are assembled according to the correct technique, ensuring balance and firmness.

The entire system must be fixed to the floor with expansion bolts, tighten the connections, and check the load capacity. With automatic racking systems, technicians will also check the sensors and control software.

Installation should be performed by a professional unit, complying with safety standards such as OSHA or EN to ensure efficient operation and avoid risks during use.

How to install warehouse racking?

What is the difference between shelving and racking?

In the field of storage, shelving (lightweight shelves) and racking (pallet racking systems) are both used to optimize warehouse space. However, they have distinct differences in design, purpose of use and load capacity:

| Shelving | Racking | |

| Purpose of use | For light, small goods, manual picking | For heavy, bulky goods, forklift picking |

| Load capacity | Light load (from 50–200 kg/floor) | Large load (from 500–3000 kg/pallet or more) |

| Method of picking | Manual picking by staff | Using forklift or supporting equipment |

| Shelf height | Usually from 1.5m – 2.5m | Can be up to 10m or more |

| Common applications | Offices, stores, small parts warehouses | Industrial warehouses, logistics warehouses, cold storage |

Comparison between shelving and racking

How much does it cost to install a warehouse racking system?

The investment cost for a warehouse racking system depends on many factors such as the type of rack used, the design load, the height of the rack, the warehouse area as well as the accompanying technical requirements.

In particular, simple racks such as Selective racks are often affordable, ranging from $1000 – $2000 while modern systems such as Shuttle racks or AS/RS can cost tens to hundreds of millions of VND due to the integration of automation technology.

How much does it cost to install a warehouse racking system?

What is a reputable warehouse racking system provider in Malaysia?

If you are uncertain about where to purchase a warehouse racking system, DNC Automation is an excellent option for you. Many customers have trusted DNC to provide automation solutions in the production process and have had positive experiences because:

- DNC is a leading technology, automation, and engineering company in Malaysia with over 15 years of experience in the field of automation

- System integration machinery, Internet of Things (IoT), Industry 4.0, and WinCC Scada System

- Diverse designs and sizes are suitable for many domestic and foreign houses. The equipment is 100% genuine and imported from Malaysia.

Please contact us via the hotline below if you have any questions about the product, we are happy to answer you!

- 12 views

- 0 Comment

Recent Comments