Beyond the Assembly Line: How End-of-Line Automation Redefines Packaging Efficiency

In modern manufacturing, the end of the line is where true efficiency is tested. Packaging, labeling, and palletizing may seem routine, but they determine how fast products reach the market — and how well your brand delivers consistency. End-of-line automation bridges production and logistics, transforming the last step into a strategic advantage for performance, traceability, and cost control.

What Is End-of-Line Packaging Automation?

End-of-line (EOL) packaging automation refers to the use of automated machinery and robotics to handle the final stages of the packaging process — including case forming, sealing, labeling, palletizing, and wrapping. Instead of relying on manual labor, automated systems streamline how products are prepared for storage or shipment at the end of a production line.

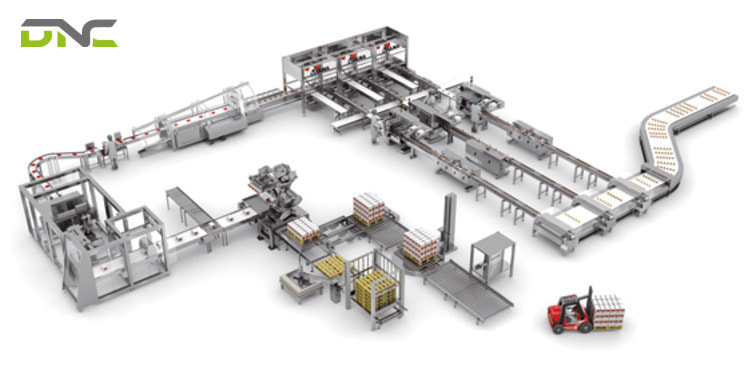

A typical EOL automation setup integrates conveyors, vision inspection systems, robotic palletizers, and automated labelers — all coordinated through a central control system (PLC or HMI). This enables continuous, synchronized operation across different packaging steps.

The primary goal is to enhance efficiency, accuracy, and consistency, ensuring every product leaving the line meets quality standards while minimizing human error and bottlenecks.

Why Is End-of-Line Automation Important for Modern Manufacturing?

End-of-line automation plays a vital role in helping manufacturers stay competitive in today’s fast-paced industrial environment. Its importance can be understood through the following key points:

- Addresses modern production challenges: Supports faster order fulfillment, adapts to rising e-commerce demand, and handles increasing product variety with high flexibility and reliability.

- Reduces dependency on manual labor: Automates repetitive, labor-intensive tasks like box sealing, labeling, and pallet stacking — minimizing workplace injuries and ensuring consistent output even during labor shortages.

- Improves accuracy and product quality: Automated systems ensure every package is correctly labeled, sealed, and prepared for shipment, minimizing human error and enhancing overall process consistency.

- Enhances traceability and product safety: Integrated sensors and vision systems verify packaging quality, barcode accuracy, and product count, ensuring compliance and safety throughout the supply chain.

- Boosts Overall Equipment Effectiveness (OEE): When connected to enterprise platforms like WMS, MES, or ERP, automated systems provide real-time data for performance analysis, downtime tracking, and process optimization.

- Supports Industry 4.0 transformation: Aligns manufacturing with digital transformation goals by enabling data-driven decision-making, real-time visibility, and long-term operational sustainability.

End-of-line automation plays a vital role in helping manufacturers stay competitive in today’s fast-paced industrial environment

How Does an End-of-Line Packaging System Work?

An end-of-line (EOL) packaging system streamlines the final stage of production — where finished goods are prepared, packed, and shipped. By combining conveyors, case packers, labelers, palletizers, and inspection systems into one integrated line, manufacturers can achieve seamless flow from production to dispatch. Below are 6 steps look at how a modern EOL packaging system operates.

Step 1 — Product Infeed & Accumulation: Finished goods enter the end-of-line area from the production line. Conveyors and sensors organize and buffer the products, ensuring a steady, well-timed flow for downstream operations.

Step 2 — Case Forming & Packing: Automatic case erectors form cartons, while robotic pick-and-place systems load products inside. This process increases packing speed and ensures precise, consistent placement for every package.

Step 3 — Sealing & Labeling: Once packed, cartons are automatically sealed with tape, glue, or shrink wrap. Integrated labeling systems print and apply product details, barcodes, and expiration dates accurately and efficiently.

Step 4 — Inspection & Quality Control: Vision sensors and checkweighers inspect barcode accuracy, label quality, and seal integrity. Any defective or non-compliant packages are automatically rejected to maintain quality standards.

Step 5 — Palletizing & Wrapping: Robotic palletizers stack boxes onto pallets in optimized patterns, followed by wrapping or strapping for transport security. This step improves space utilization and ensures safe handling during logistics.

Step 6 — Conveyor Integration: Completed pallets or cartons are transferred via conveyors to the warehouse or shipping area. The system connects with WMS or MES software for real-time tracking, data collection, and inventory updates.

6 steps look at how a modern EOL packaging system operates

What Are the Key Benefits of End-of-Line Packaging Automation?

Implementing end-of-line (EOL) packaging automation offers a wide range of operational, financial, and strategic advantages for manufacturers:

- Higher throughput and productivity: Automated case packers, sealers, and palletizers can run continuously with minimal downtime, significantly increasing production output and meeting growing customer demands.

- Consistent product quality and reduced rework: Automation minimizes human error, ensuring each product is correctly packed, sealed, and labeled. This consistency leads to fewer product returns and quality issues.

- Lower labor costs and improved workplace safety: By automating repetitive, heavy, or ergonomically risky tasks, factories can reduce labor dependency while enhancing worker safety and compliance with occupational standards.

- Better traceability and real-time visibility: Integrated sensors, barcode scanners, and software systems track every product from packaging to dispatch, improving transparency and enabling quick root-cause analysis when issues occur.

- Scalability and flexibility for future product changes: Automated lines can be easily reprogrammed or adjusted to handle different packaging formats or SKUs, supporting flexible manufacturing and business growth.

Benefits of End-of-Line Packaging Automation

What Challenges Should Manufacturers Consider Before Implementing EOL Automation?

While the benefits are significant, successful deployment of end-of-line packaging automation requires careful planning and consideration:

- High initial investment and ROI calculation: Automation systems involve upfront costs for equipment, integration, and software. Manufacturers must assess ROI timelines based on labor savings, throughput gains, and quality improvements.

- Space constraints and layout optimization: EOL systems, especially palletizers or wrapping machines, require proper floor space and workflow design to ensure efficient material handling and accessibility.

- Integration with legacy systems and existing production lines: Seamless communication between new EOL equipment and existing conveyors, PLCs, or ERP/WMS systems is essential for synchronized operations and data flow.

- Maintenance, spare parts, and technical expertise: Regular maintenance and the availability of trained technicians are crucial to minimize downtime. Local support from automation partners helps ensure long-term system performance.

How to Choose the Right End-of-Line Automation Partner?

Selecting the right end-of-line automation partner is a critical decision that directly impacts your production efficiency, system reliability, and long-term ROI. Beyond just equipment supply, a trusted automation partner acts as a technology advisor—helping you design, integrate, and maintain a fully optimized packaging line.

- Evaluate industry experience and technical expertise: Choose a partner with proven experience in your specific sector—such as food & beverage, FMCG, pharmaceuticals, or manufacturing.

- Assess system integration capability: A strong automation partner should be able to integrate multiple technologies—robotic palletizers, conveyors, labeling systems, AGVs, and data software—into one synchronized solution. Compatibility with existing ERP, MES, or WMS platforms ensures smooth data flow and real-time visibility across your operations.

- Verify local engineering support and after-sales service: Reliable local support is essential for minimizing downtime and keeping your packaging line running efficiently. Ensure your partner offers preventive maintenance, on-site troubleshooting, spare parts availability, and operator training.

- Consider scalability and customization: Your automation investment should evolve with your business. Look for a partner that offers modular and scalable designs—so new product formats, volumes, or technologies can be added later without complete system replacement.

- Review past projects and client references: Ask for real-world case studies or client testimonials that demonstrate the partner’s success in similar automation projects. This provides valuable insight into their reliability, technical execution, and post-installation support.

Choose a partner with proven experience in your specific sector

Frequently Asked Questions (FAQ) — End-of-Line Packaging Automation

1. What processes are typically automated at the end of the line?

EOL automation commonly includes case erecting, product packing, sealing, labeling, inspection, palletizing, and stretch wrapping. Each process can be integrated to create a seamless, fully automated workflow from production to shipping.

2. Can EOL automation integrate with existing equipment?

Yes. Modern systems are designed to integrate with existing conveyors, case sealers, or ERP/WMS software through PLCs and industrial communication protocols like Ethernet/IP or Modbus.

3. What’s the ROI or payback period for packaging automation?

Most manufacturers experience ROI within 18–36 months, depending on production scale, labor savings, and operational improvements. EOL automation reduces rework and improves throughput, accelerating payback.

4. How much space is needed for an automated EOL system?

Space requirements vary depending on line speed, product size, and palletizing configuration. Compact robotic palletizers and modular conveyors can be customized for limited floor plans.

5. Does DNC offer maintenance and operator training services?

Yes. DNC Automation provides end-to-end services, including system design, installation, operator training, and ongoing maintenance. Their local engineering team in Malaysia ensures responsive support and spare parts availability.

Conclusion

End-of-line packaging automation is no longer just a productivity upgrade—it’s a strategic investment for manufacturers seeking speed, precision, and long-term cost efficiency. By automating the final stage of packaging, businesses can streamline operations, minimize human error, and create a more connected, data-driven production environment.

At DNC Automation, we specialize in designing and integrating custom end-of-line automation systems tailored to your production needs. From case packing, labeling, and robotic palletizing to conveyor integration and vision inspection, our team delivers turnkey solutions that connect your production to logistics seamlessly.

With over a decade of experience in industrial automation across Malaysia and ASEAN, DNC combines deep engineering expertise, local support, and world-class technologies to help factories transition into smart, efficient, and future-ready operations. Whether you’re upgrading an existing line or building a new facility, DNC Automation is your trusted partner in end-of-line innovation.

- 2 views

- 0 Comment

Recent Comments