Overview of Automated Storage Retrieval Systems (ASRS): Applications, Benefits, Components…

What is the ASRS? Automated Storage and Retrieval Systems (ASRS) are high-tech, computer-controlled solutions designed to store and retrieve inventory or materials automatically from defined storage locations. These systems are widely used in warehouses, manufacturing facilities, distribution centers, and logistics hubs to streamline operations, reduce manual labor, and maximize storage efficiency.

In today’s era of fast-paced logistics and omnichannel retail, ASRS has become a game-changer. It enables businesses to manage their inventory with unmatched precision and speed, resulting in lower operational costs and higher customer satisfaction.

What are the salient features of ASRS?ASRS integrates advanced automation technology and intelligent software to manage storage operations intelligently. Here are the key features that define a powerful ASRS:

- Computerized inventory management: Every item is tracked in real-time, minimizing loss and misplacement.

- Automated storage and retrieval machines (SRM): These systems use machines to pick and place goods with minimal human intervention.

- Customizable storage layout: The system can be easily adjusted to accommodate a wide range of items and various warehouse configurations.

- Integrated software system: Warehouse management system (WMS) and Warehouse control system (WCS) work in sync to create seamless operations for inventory management.

- Scalable architecture: ASRS can grow as your business and storage needs expand.

- High-Density Storage: This approach allows for storing more goods in a smaller area by utilizing vertical space, which is the most innovative and modern warehouse management model today.

What are the basic components of ASRS?

What are the basic components of ASRS?

Storage and Retrieval Machines (SRMs)

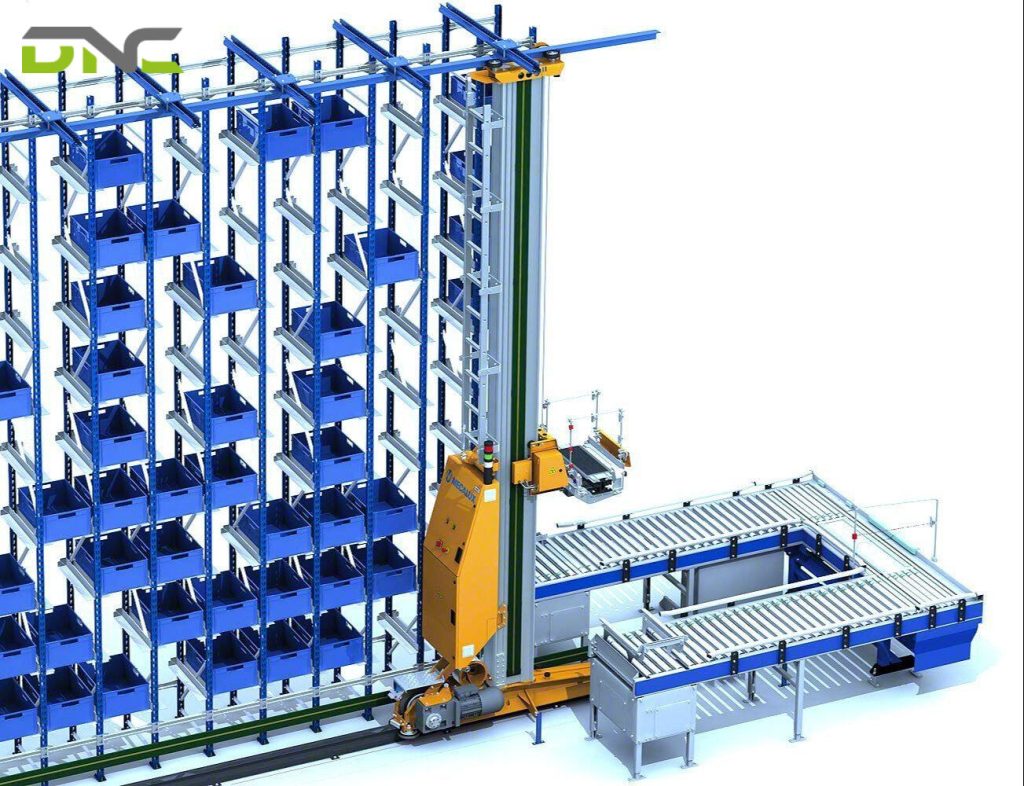

Storage and Retrieval Machines (SRMs), commonly referred to as carts, stackers, or robotic arms, are the core mechanical components of an ASRS. These machines are responsible for automatically placing and retrieving items from storage locations in a racking system. They are equipped with sensors and actuators to accurately locate and handle items, thereby significantly reducing the need for human intervention and increasing operational efficiency.

Rack Structures

A rack structure is the static frame that holds the stored goods. It is specifically designed to match the size, weight, and handling requirements of the inventory it holds. Racks can come in a variety of configurations, from narrow, high-rise designs used in high-density storage to wider configurations for bulkier items.

Warehouse Control System (WCS)

The Warehouse Control System (WCS) is the operational brain of the ASRS. This software handles real-time control of equipment such as SRMs, conveyors, and AGVs. The system monitors system performance and ensures tasks are performed accurately and efficiently, optimizing throughput and minimizing delays due to equipment downtime or human error.

Conveyor or AGV Interface

Autonomous Guided Vehicles (AGVs) or conveyors ensure a smooth flow of materials into and out of the ASRS. Conveyors are ideal for continuous, high-speed transfers, while AGVs provide flexible, automated navigation for complex layouts. These interfaces play a vital role in reducing bottlenecks, speeding up operations, and maintaining synchronization between the warehouse and other warehouse functions.

What types of ASRS are common today?

What types of ASRS are common today?

There are many types of ASRS available on the market today, each suitable for different operational and warehouse layout needs. Depending on the needs of the manufacturing facility, there will be some popular types of ASRS such as: Conveyor ASRS, Unit Load ASRS, Vertical Lift Module (VLM) …

- Unit Load ASRS: Designed to handle large, heavy items stored on pallets. They are ideal for heavy-duty manufacturing and warehousing.

- Shuttle system: This is a flexible and scalable type of ASRS that uses automated shuttles for picking. Known for its high-speed and efficient operation.

- Conveyor ASRS, such as vertical and horizontal conveyors, operate by rotating items vertically/horizontally to deliver the desired bin to the picker.

- Vertical Lift Module (VLM): The system automatically picks up trays from the vertical column and transfers them to a convenient access point.

How does the ASRS warehouse operate?

How does the ASRS warehouse operate?

The operational process of ASRS is quite complex because it leverages a suite of hardware and software technologies, including Warehouse Execution Systems (WES), robotics, and structural automation to manage the storage and movement of goods. Here is a step-by-step overview of how an ASRS warehouse works:

- Inbound Goods: Goods are placed on a conveyor or AGV and scanned into the system.

- Store command issued: WES/WCS directs an SRM or shuttle to a designated location.

- Automatic Placement: Goods are stored precisely using robots and sensors.

- Order Trigger: When an order is placed, the system determines the location and triggers a pick.

- Goods Picked and Delivered: SRMs or shuttles pick up the goods and send them to a pick or packing station.

- Outbound Goods Processing: Goods are packed and shipped directly or sent to downstream operations.

All operations are performed with a very high degree of precision, which significantly reduces errors, labor requirements, and processing times incurred in the process.

Where is the most reputable place to provide ASRS in Malaysia?

Where is the most reputable place to provide ASRS in Malaysia?

If you’re looking for a trusted supplier of high-quality Automated Storage and Retrieval Systems (ASRS) in Malaysia, DNC Automation stands out as a top choice. With over 15 years of experience in automation, engineering, and industrial technology, DNC has earned a strong reputation for delivering reliable and fully customized ASRS solutions to businesses across various sectors.

As a leading provider of warehouse automation systems in Malaysia, DNC specializes in:

- Tailor-made ASRS solutions for different warehouse sizes and industries

- Integration with Warehouse Management Systems (WMS) and control software

- Robotics and smart automation for high-density, high-speed storage

- Industry 4.0 and IIoT integration to enable real-time monitoring and analytics

- End-to-end project management from design and installation to after-sales support

DNC Automation offers scalable ASRS configurations designed to meet the specific needs of manufacturing, logistics, retail, and 3PL operations. All systems are engineered in Malaysia using proven international standards, ensuring high performance, durability, and seamless integration with your existing infrastructure.

- 39 views

- 0 Comment

Recent Comments